Hydrophilic degradable segmented polyurethane as well as preparation method and application thereof

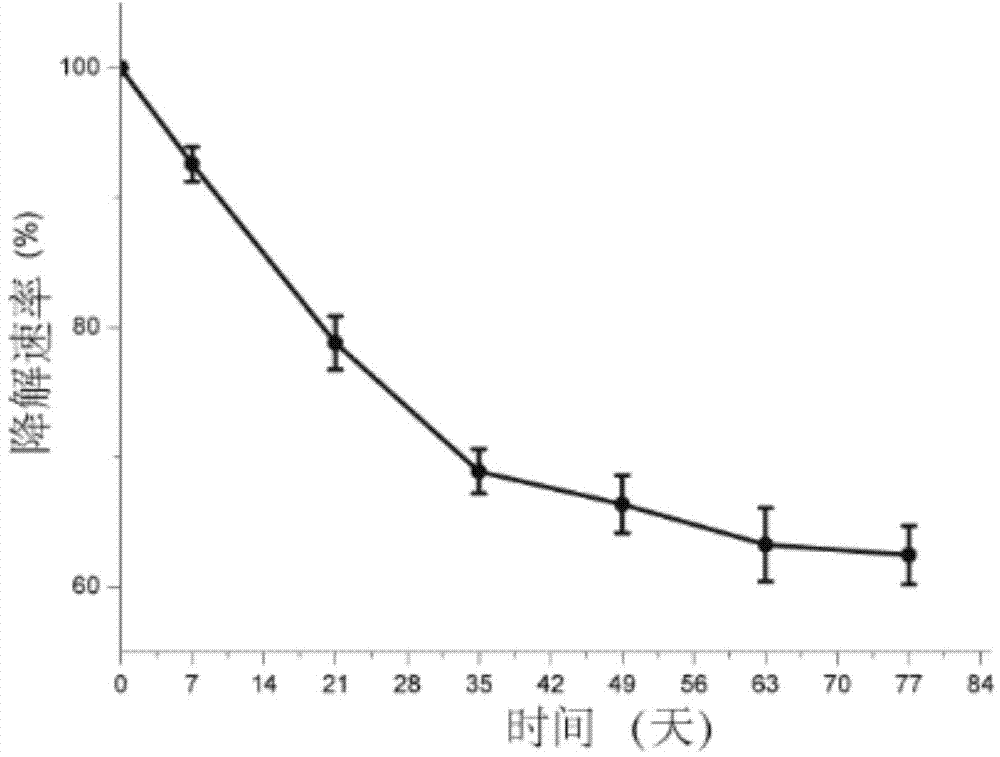

A hydrophilic, polyurethane technology, applied in the field of polymer medical materials and synthesis, to improve the hydrolysis rate, avoid secondary surgery, reduce pain and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step (1), putting 0.0875mol (10g) of ε-caprolactone monomer and 0.01mol (20g) of polyethylene glycol with a molecular weight of 2000 into a reaction vessel for vacuum dehydration treatment to obtain dehydrated raw materials;

[0037] Step (2), mixing the dehydrated raw material in step (1) with 0.3 g of iron acetylacetonate catalyst, under the protection of nitrogen, polymerized at 135° C. for 24 hours, and cooled to normal temperature to obtain a tri-block polyester polyol;

[0038] Step (3), after vacuum dehydration of the three-block polyester polyol obtained in step (2), take 3g (0.0005mol) and dissolve it in 45ml N,N-dimethylformamide organic solvent, then add 1ml (1.05g, 0.006mol) hexamethylene diisocyanate, 0.042g catalyst iron acetylacetonate, and reacted at 65°C for 2 hours under nitrogen protection to obtain a prepolymer;

[0039] Step (4), add 5ml organic solvent N,N-dimethylformamide, 0.134g (0.001mol) trimethylolpropane chain extender to the prepolymer obta...

Embodiment 2

[0042] Step (1), putting 0.175mol (20g) of ε-caprolactone and 0.01mol (20g) of polyethylene glycol with a molecular weight of 2000 into a reaction vessel for vacuum dehydration treatment to obtain dehydrated raw materials;

[0043] Step (2), mixing the dehydrated raw material in step (1) with 0.4 g of catalyst iron acetylacetonate, under the protection of nitrogen, polymerized at 130° C. for 29 hours, and cooled to normal temperature to obtain a tri-block polyester polyol;

[0044] Step (3), after vacuum dehydration of the triblock polyester polyol obtained in step (2), get 4g (0.0006mol) and dissolve it in 50mL organic solvent N,N-dimethylformamide, then add 0.002mol ( 0.3483g) toluene diisocyanate, 0.0044g catalyst iron acetylacetonate, and reacted at 60°C for 3.5 hours under the protection of nitrogen to obtain a prepolymer;

[0045] Step (4), add 5mL organic solvent N,N-dimethylformamide, 0.001mol (0.062g) chain extender ethylene glycol to the prepolymer obtained in step (...

Embodiment 3

[0047] Step (1), putting 0.35mol (40g) of ε-caprolactone and 0.01mol (20g) of polyethylene glycol with a molecular weight of 2000 into a reaction vessel for vacuum dehydration treatment to obtain dehydrated raw materials;

[0048] Step (2), mixing the dehydrated raw material in step (1) with 0.6 g of catalyst iron acetylacetonate, under the protection of nitrogen, polymerized at 140° C. for 19 hours, and cooled to normal temperature to obtain a tri-block polyester polyol;

[0049] Step (3), after vacuum dehydration of the three-block polyester polyol obtained in step (2), get 10g (0.001mol) and dissolve it in 77mL organic solvent N,N-dimethylformamide, then add 5g (0.02mol ) diphenylmethane diisocyanate, 0.33g catalyst iron acetylacetonate, and reacted at 70°C for 1.5 hours under the protection of nitrogen to obtain a prepolymer;

[0050] Step (4), add 9 mL of organic solvent N,N-dimethylformamide, 1.44 g (0.01 mol) of chain extender 1,4-cyclohexanediol to the prepolymer obtai...

PUM

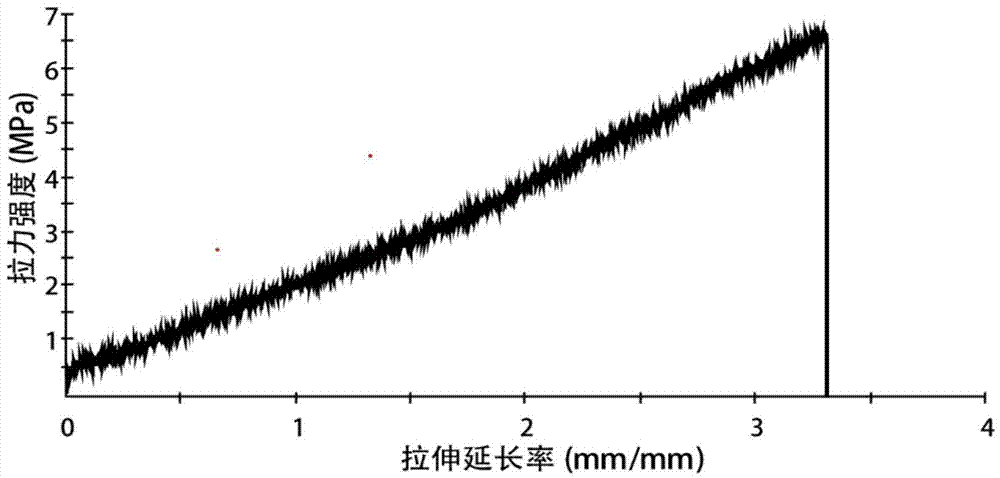

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com