Patents

Literature

125results about How to "Achieve anti-corrosion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

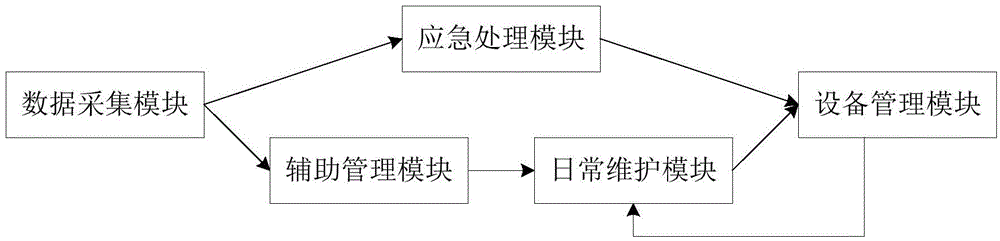

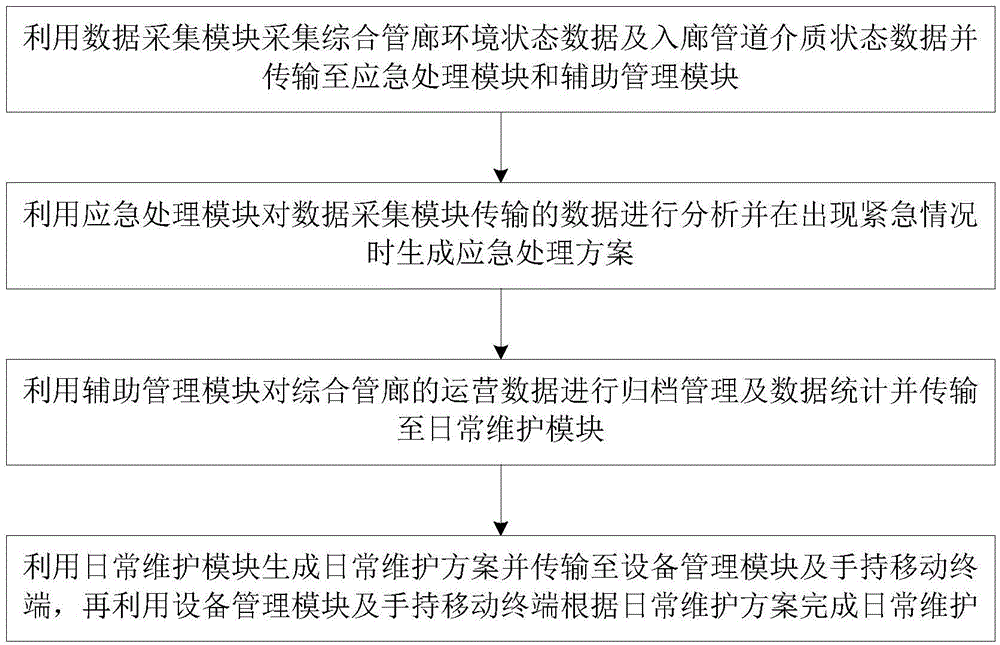

System and method for comprehensive pipe gallery management based on BIM

InactiveCN104880986AAccurate analysisRealize 3D visualization managementProgramme controlComputer controlComputer moduleData acquisition

The invention discloses a system and a method for comprehensive pipe gallery management based on a BIM. The system comprises a data acquisition module, an emergency processing module, an auxiliary management module, a daily maintenance module, and a device management module. The method comprises: using the data acquisition module to acquire environment state data of a comprehensive pipe gallery and medium state data in a gallery accessing pipe, using the emergency processing module to generate an emergency processing scheme when emergency occurs, using the auxiliary management module to perform archive management and data statistics on operating data of the comprehensive pipe gallery, and using the daily maintenance module and the device management module to perform daily maintenance. The system and the method realize three-dimensional visual management on the whole comprehensive pipe gallery, ensure security of the comprehensive pipe gallery and life and property safety of workers, and improve operating efficiency.

Owner:CHINA CONSTR UNDERGROUND SPACE

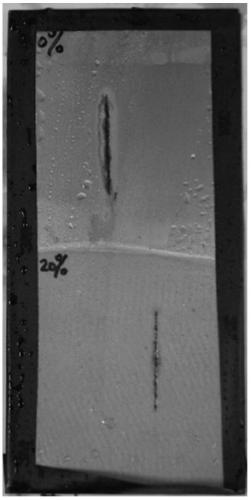

Self-repair coating with anticorrosion and antifouling double functions and method for preparing self-repair coating

InactiveCN109082193AGood coordinationWide range of applicationsAntifouling/underwater paintsPaints with biocidesChemistryEnvironmentally friendly

The invention belongs to the field of marine anticorrosion and antifouling technologies, and particularly relates to a self-repair coating with anticorrosion and antifouling double functions and a method for preparing the self-repair coating. The method includes preparing macromolecular micro-capsules with loaded environment-friendly antifouling agents and self-repair reagents; adding dispersing auxiliaries into the macromolecular micro-capsules and dispersing the micro-capsules in resin to obtain the self-repair coating. The self-repair coating and the method have the advantages that the micro-capsules can be ruptured to release the self-repair reagents and the environment-friendly antifouling agents in the micro-capsules when the self-repair coating is damaged, accordingly, micro-crack can be repaired, and microorganisms can be stopped from being attached to the micro-crack; the self-repair coating can have the self-repair anticorrosion and antifouling functions by the aid of high value-added effects of the micro-capsules as compared with the traditional self-repair anticorrosion coatings, and the loaded antifouling agents are environmentally friendly and are high in efficiency and broad in spectrum; raw materials for the self-repair coating are inexpensive and are easily available, synthesis procedures are easy to control, special conditions or equipment can be omitted, themethod is high in yield, and obvious self-repair anticorrosion and antifouling effects can be realized by the self-repair coating.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Strongly corrosion-resistant stranded galvanized steel wire and manufacturing method thereof

InactiveCN104451434AImprove tensile propertiesImprove corrosion resistanceTextile cablesWire rodCorrosion resistant

The invention discloses a strongly corrosion-resistant stranded galvanized steel wire. The strongly corrosion-resistant stranded galvanized steel wire is prepared from the following components in percentage by weight: 0.83-0.85% of C, 0.76-0.78% of Mn, 0.09-0.13% of Si, 0.53-0.55% of Cr, 0.16-0.18% of Mo, 0.41-0.43% of Ni, 0.015-0.025% of V, 0.003-0.005% of B, less than or equal to 0.015% of P, less than or equal to 0.012% of S, less than or equal to 0.017% of Cu, less than or equal to 0.005% of N and the balance of Fe and inevitable impurities. The invention also discloses a manufacturing method of the strongly corrosion-resistant stranded galvanized steel wire; the strongly corrosion-resistant stranded galvanized steel wire is high in corrosion resistance and fatigue durability, high in wire steel purity, uniform in component and structure, and long in service life.

Owner:ROLLAS POWER TECH CO LTD

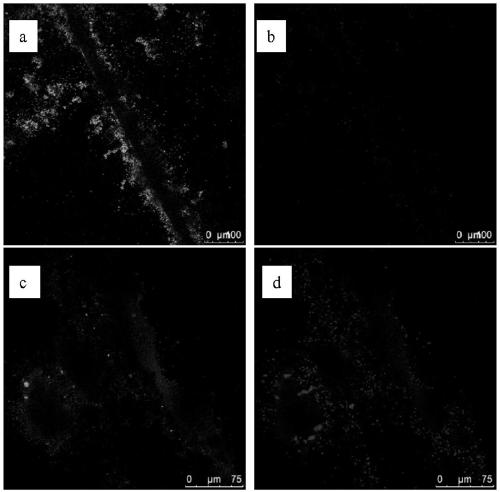

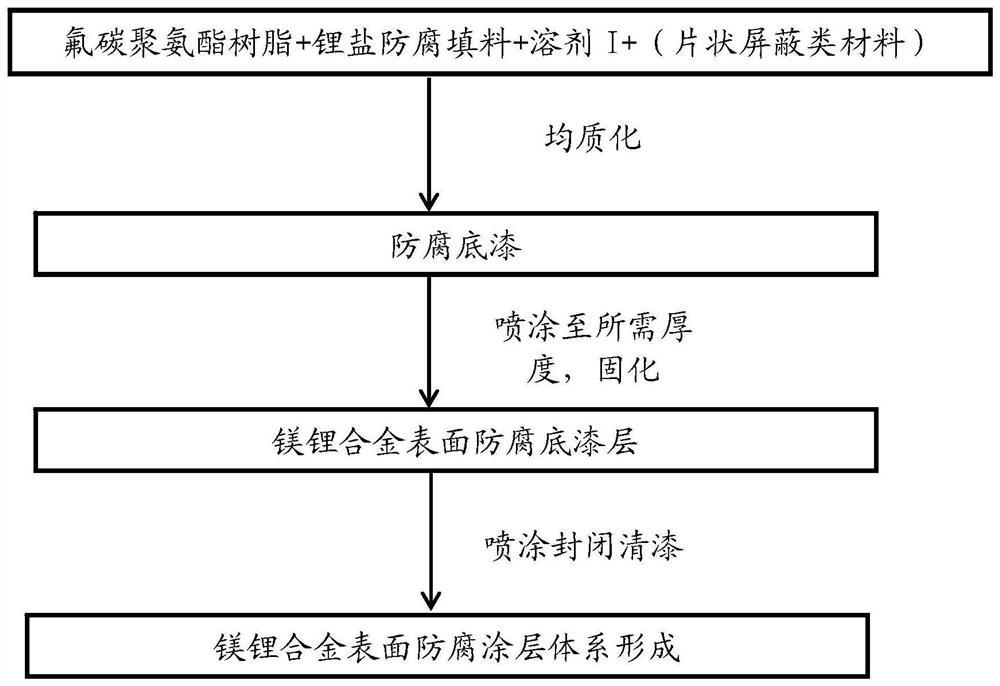

Composition for forming magnesium-lithium alloy surface anticorrosive coating system and preparation method of anticorrosive coating system

ActiveCN112029394ATune performanceAchieve anti-corrosion effectLiquid surface applicatorsAnti-corrosive paintsLithiumCoating system

The invention provides a composition for forming a magnesium-lithium alloy surface anticorrosive coating system and a preparation method of the anticorrosive coating system, the composition comprisesanticorrosive primer and sealing varnish, and the anticorrosive primer is prepared from the following raw materials in parts by mass: 70-100 parts of high-density tough resin, 1-25 parts of lithium salt inorganic matter and 0-15 parts of flaky shielding material; the sealing varnish comprises high-density resin; the anticorrosive primer is used for forming an anticorrosive primer primer layer on the surface of the magnesium-lithium alloy, and the sealing varnish is used for forming a sealing varnish layer on the surface of the anticorrosive primer layer; when the anticorrosive coating system is prepared, the anticorrosive primer layer is firstly formed on the surface of the magnesium-lithium alloy, and then the sealing varnish layer is formed. According to the composition and the preparation method of the coating system, the corrosion resistance is excellent, the corrosion resistance effect that the magnesium-lithium alloy resists neutral salt mist for 1000 h is achieved, the composition and the coating system can be used for corrosion resistance of the surfaces of aircrafts such as missile and rocket ships adopting the light magnesium-lithium alloy, the environmental adaptabilityis improved, and meanwhile the composition and the coating system have potential wide application prospects in the civil field.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

Preparation method of polyaniline-polyacrylate compound

ActiveCN103897184AAchieve molecular level dispersionGood compatibilityAnti-corrosive paintsSolventAniline

The invention discloses a preparation method of a polyaniline-polyacrylate compound, and relates to the technical field of polyaniline synthesis. The preparation method comprises the following steps: firstly, enabling part of active solvent to be reacted with part of mixed monomers and initiator, then, heating the reacted mixed system, next, dropwise adding the other part of mixed monomers, initiator and active solvent, and carrying out preserved heat reaction until the reaction is ended; cooling the system generated through the reaction to 0-20 DEG C, adding aniline, uniformly stirring, then, dropwise adding an oxidative initiator solution, and then, reacting at normal temperature until the reaction is ended. Polyaniline and polyacrylate resin in the polyaniline-polyacrylate compound disclosed by the invention are formed into a molecular compound to be added into an anticorrosive coating, so that not only is the uniform dispersion of polyaniline in the coating realized, but also polyacrylate resin in the compound can be used for promoting the compatibility of the polyaniline and film forming materials in an anticorrosive coating, so that the long-acting corrosion resistance and environment friendliness of polyaniline in a heavy anticorrosive coating can be realized.

Owner:YANGZHOU UNIV

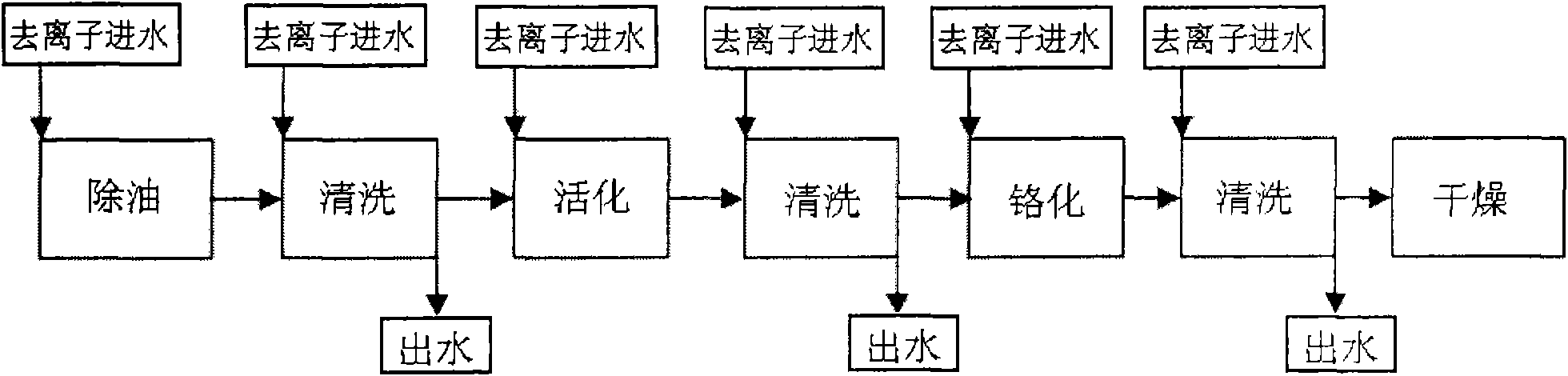

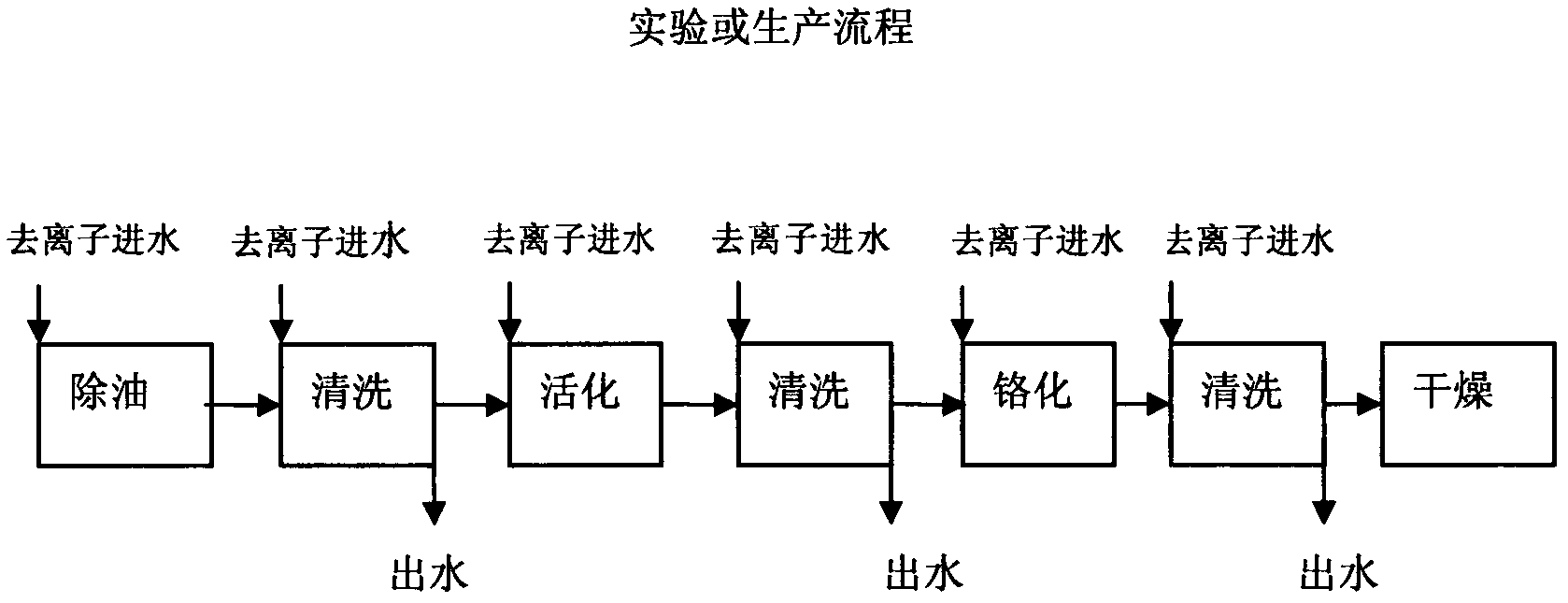

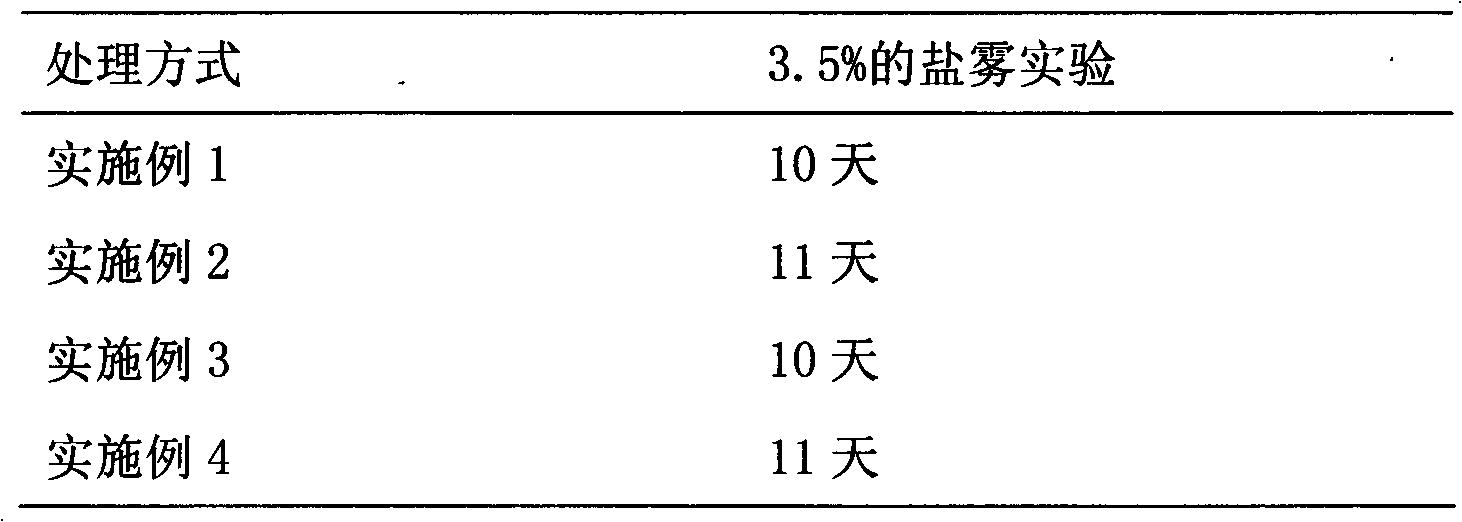

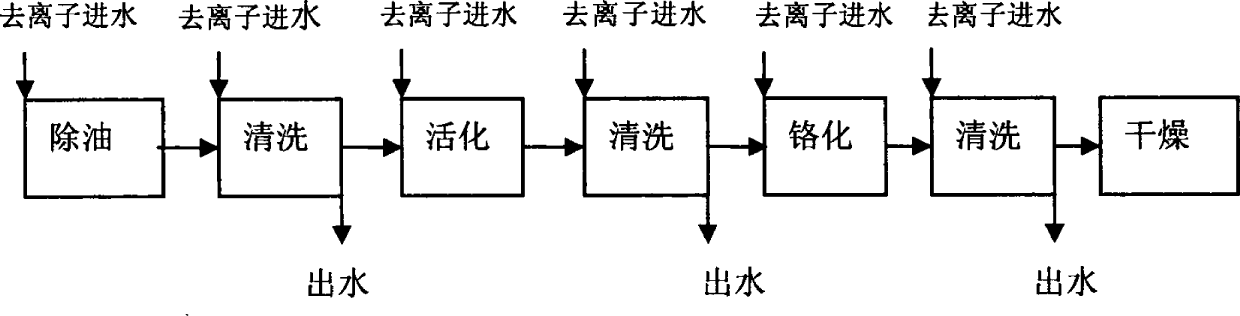

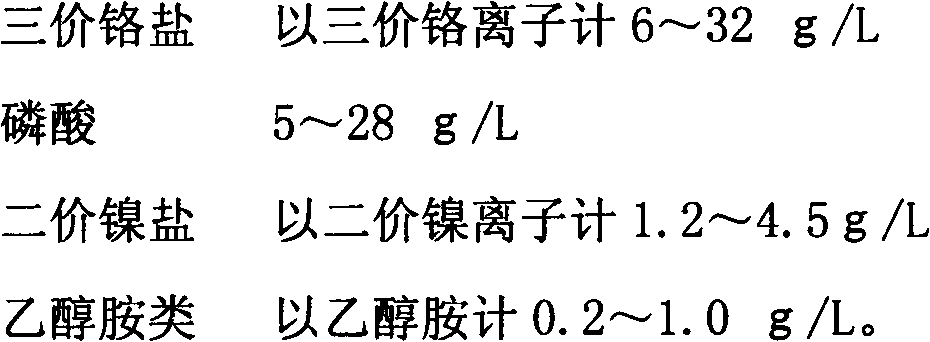

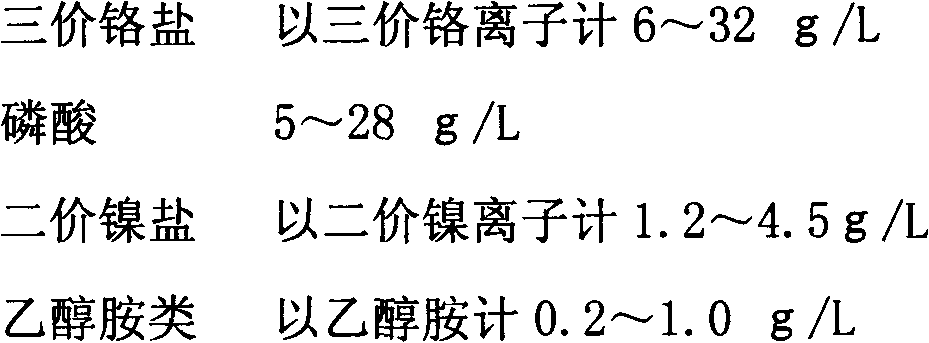

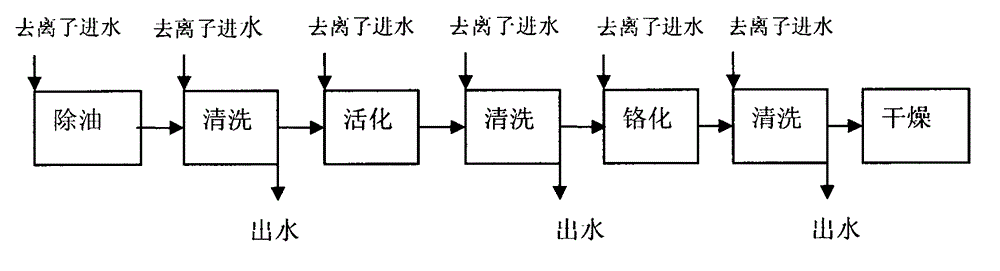

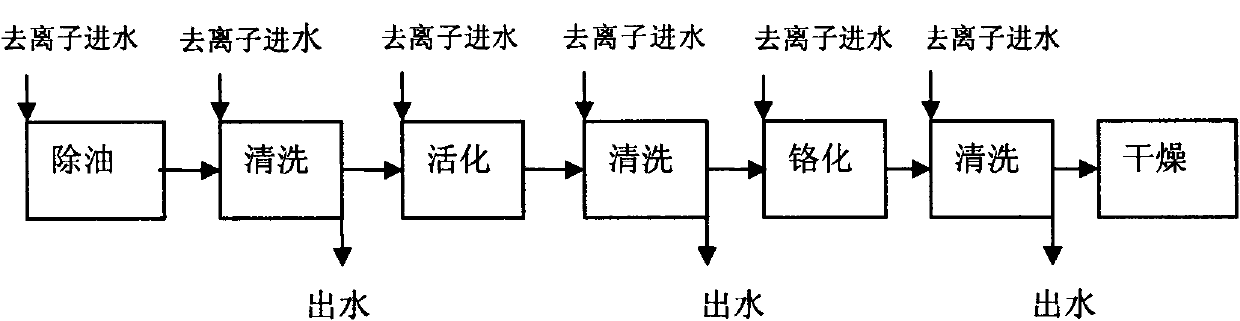

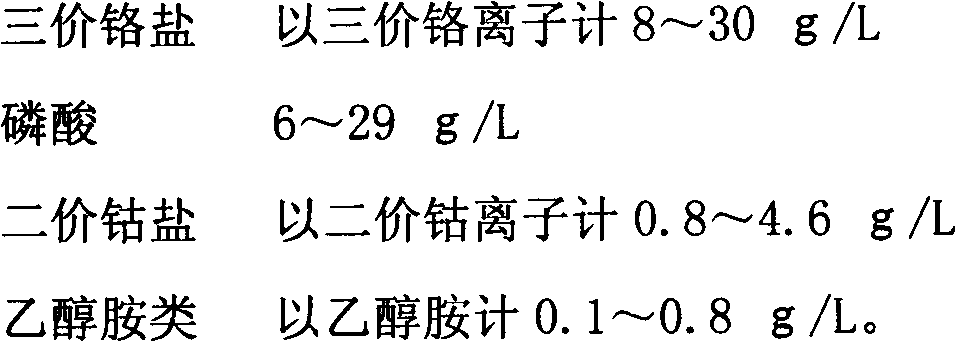

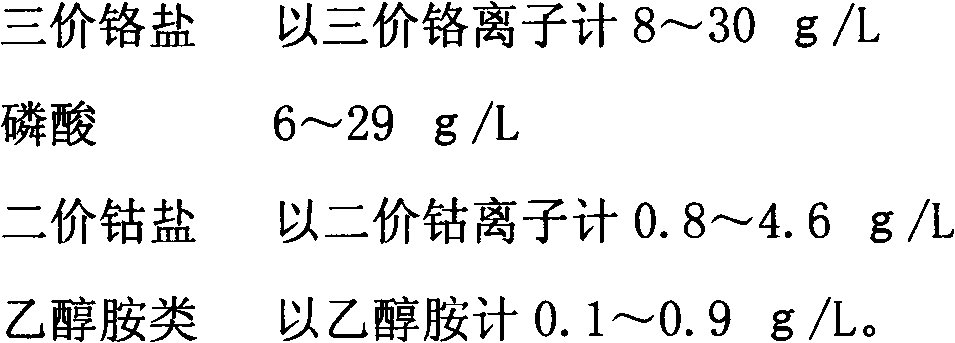

Method for preparing aluminium alloy/trivalent chromium composite conversion film and film-forming liquid thereof

InactiveCN102174694AImprove corrosion resistanceAchieve anti-corrosion effectMetallic material coating processesManganeseEthanolamines

The invention discloses a method for preparing an aluminium alloy / trivalent chromium composite conversion film and a film-forming liquid thereof. An inorganic corrosion inhibitor divalent manganese salt and an organic corrosion inhibitor ethanolamine are added into the coating-forming liquid, and a trivalent chromium composite conversion film can be formed on the surface of an aluminium alloy when the film-forming liquid is used to process an aluminium or aluminium alloy workpiece. Compared with the trivalent chromium conversion film with a single film layer, the aluminium alloy / trivalent chromium composite conversion film prepared by the method can improve the corrosion resistance of the aluminium alloy, and achieve the same corrosion resistance effect with that of a hexavalent chromium chemical conversion film.

Owner:GUANGXI UNIV FOR NATITIES

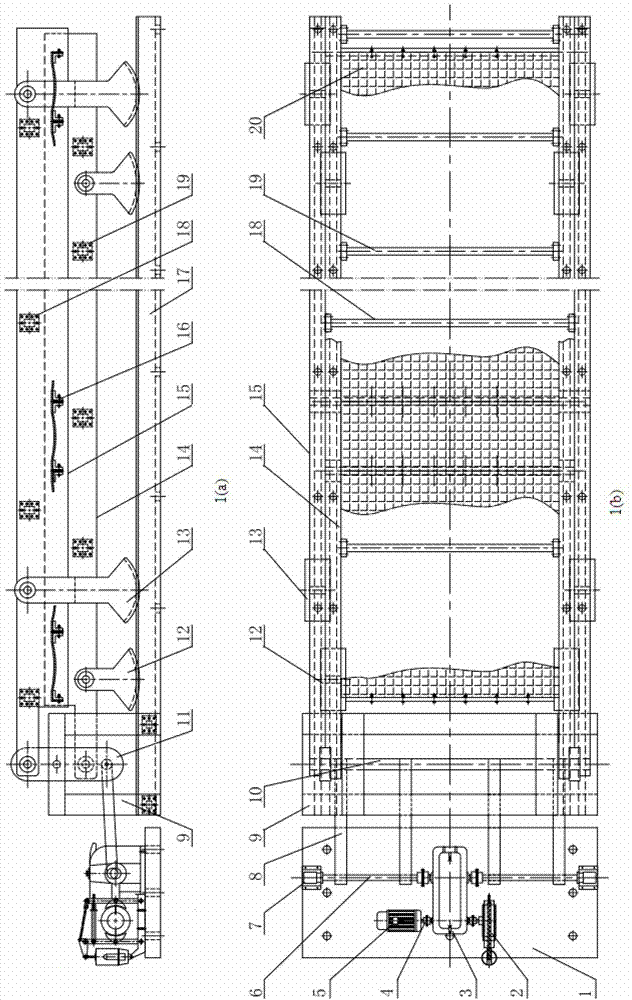

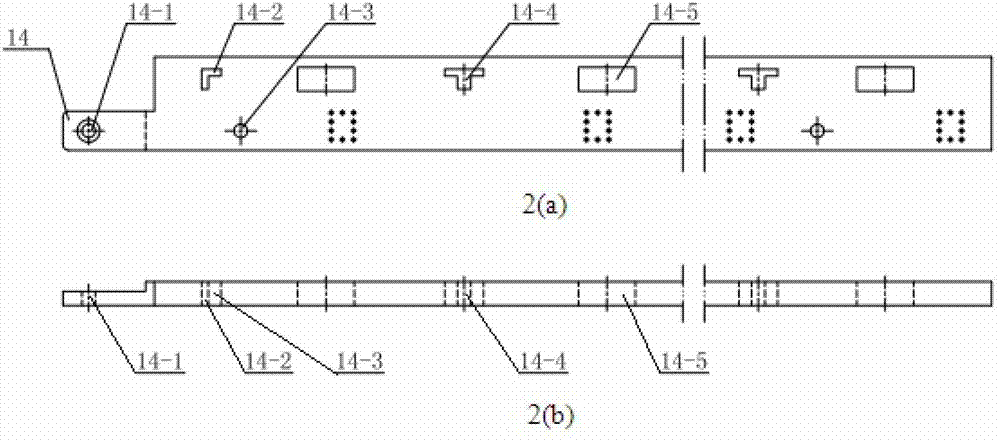

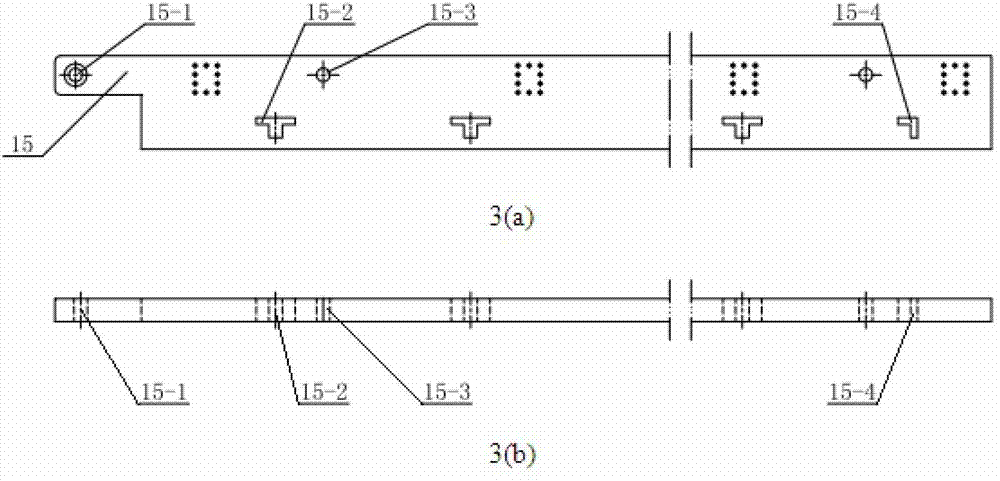

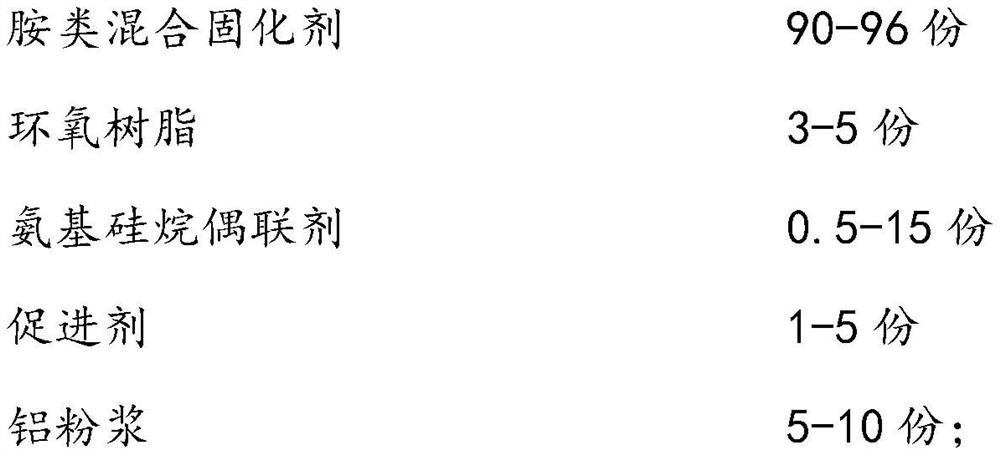

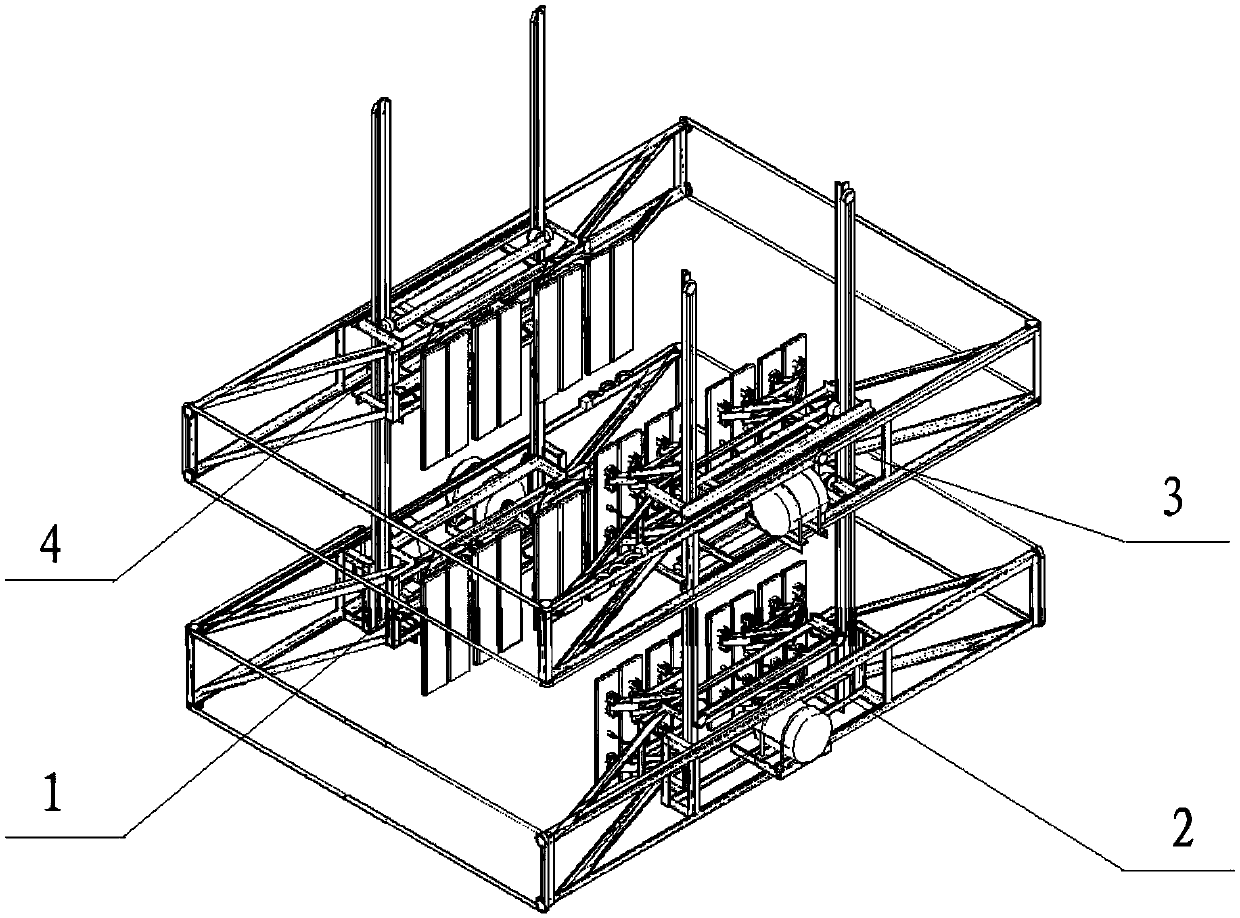

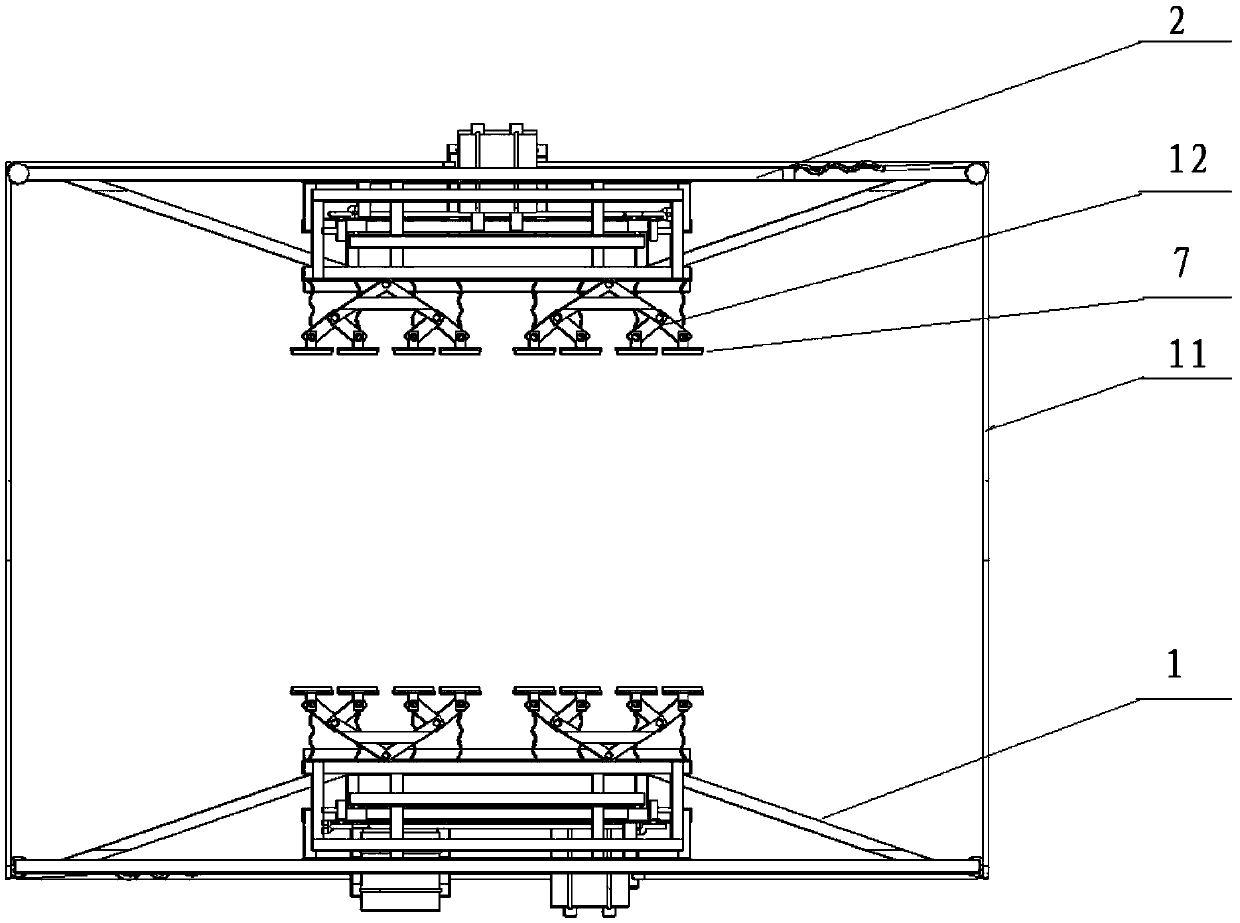

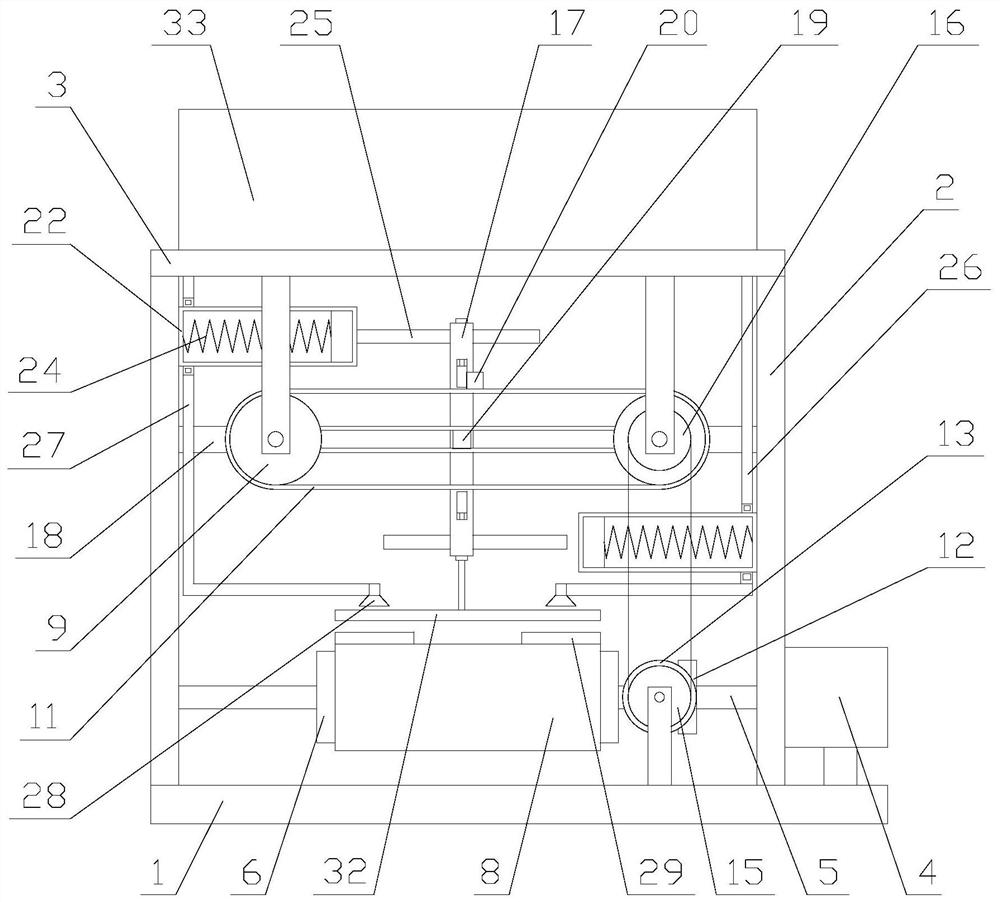

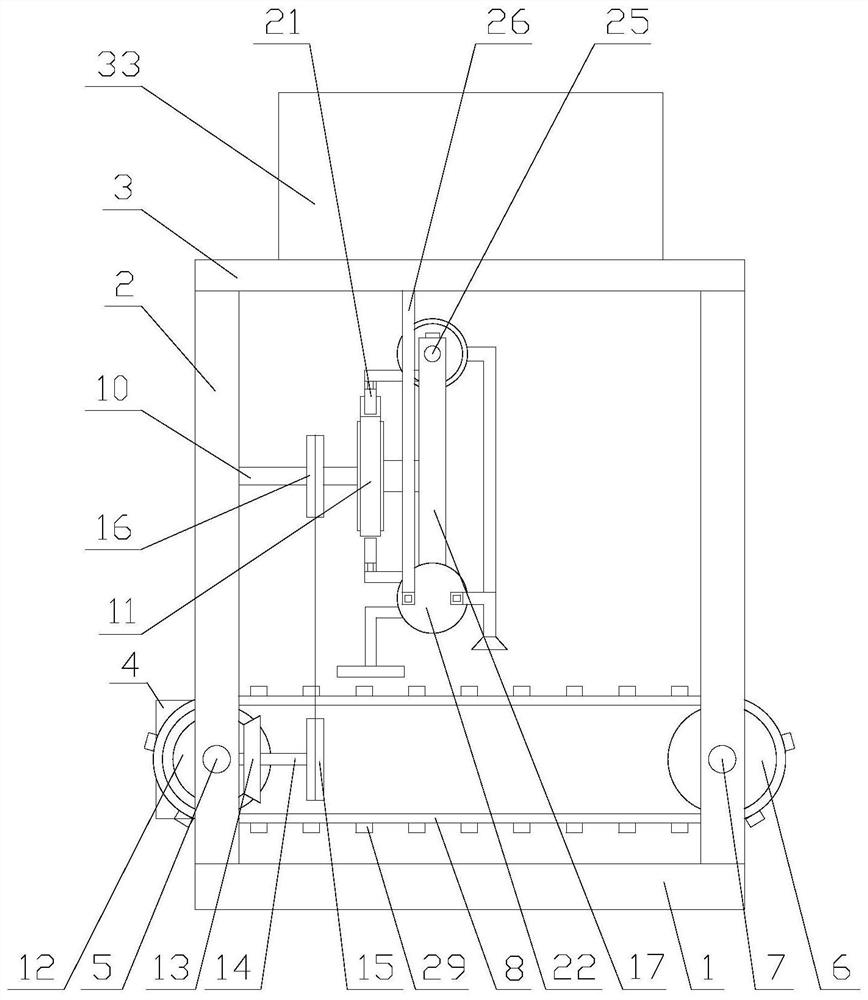

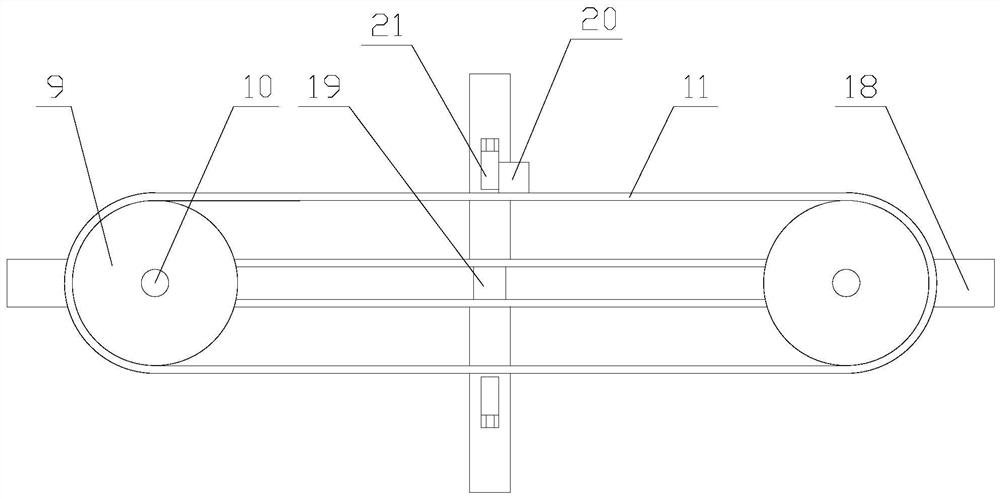

Bilateral-sector-support flip-flow screen

InactiveCN103240223AReduce processing complexityAchieve anti-corrosion effectSievingScreeningMotor driveReduction drive

The invention discloses a bilateral-sector-support flip-flow screen. The bilateral-sector-support flip-flow screen mainly comprises a brake, a speed reducer, a motor, two eccentric shafts, four connecting rod, a swing rod, an inner screen frame sector support, an outer screen frame sector support, an inner screen frame, an outer screen frame, screen fixing steel angles, a sector support guide rail, a segmented polyurethane screen surface and the like. The two eccentric shafts are connected with the swing rod by the four connecting rods to form a crank swing rod mechanism. When the motor drives the eccentric shafts to rotate through the speed reducer, under the action of the connecting rods, the swing rod swings around a swing rod hinge hole back and forth so as to drive the inner screen frame and the outer screen frame to move relatively; and since two ends of the segmented polyurethane screen surface are fixed by the screen fixing steel angles of the inner screen frame and the outer screen frame, tension and relaxation scratching movement of the segmented polyurethane screen surface is realized. The inner screen frame support and the outer screen frame support can form an ejection surface with a certain inclination angle when the segmented polyurethane screen surface is tensioned, so that materials can bear large self weight and high impact pressure when forwarding and penetrating the screen. The bilateral-sector-support flip-flow screen has the advantages of novel working principle, simple structure, high bearing capacity and high reliability.

Owner:中国矿业大学盱眙矿山装备与材料研发中心 +1

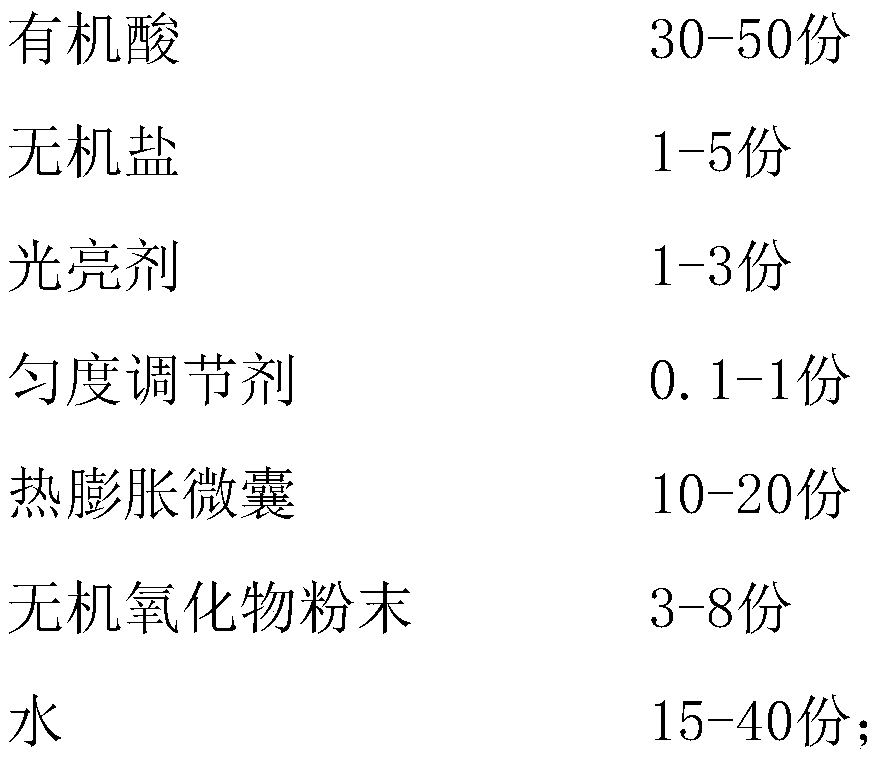

Environmentally friendly brick surface anti-skid agent and preparation method thereof

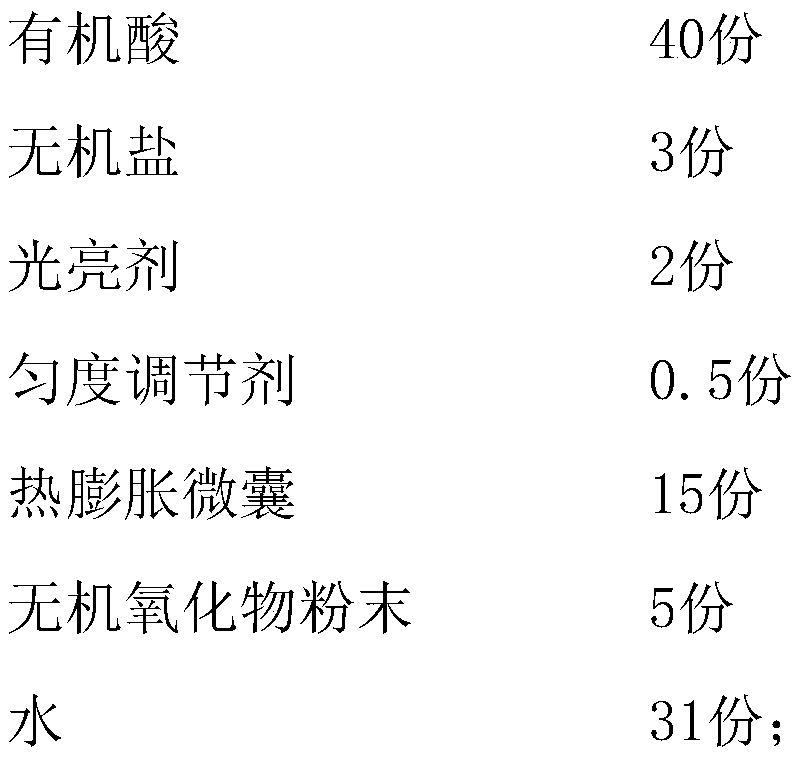

InactiveCN109970466AReduce corrosionIncrease surface frictionMicroballoon preparationMicrocapsule preparationOrganic acidInorganic salts

The invention relates to the technical field of brick surface anti-skid processing agents, and specifically relates to an environmentally friendly brick surface anti-skid agent and a preparation method thereof. The environmentally friendly brick surface anti-skid agent comprises following raw materials: organic acids, inorganic salts, a brightener, an evenness adjuster, a thermally expanded microcapsule, inorganic oxide powder, and water. The particle size of the thermally expanded microcapsule is 20 to 35 [mu]m. Inorganic oxide powder is adhered on the surface of the thermally expanded microcapsule. The anti-skid agent can form a large amount of micro grooves in the surface of a brick; thermally expanded microcapsules will be embedded in the micro grooves; after a heat treatment (110 to 130 DEG C), the thermally expanded microcapsules expand, tightly press against the lateral walls of the micro grooves, and protrude outwards from the micro grooves; many micro bumps are formed on the brick surface, the friction force of the brick surface is increased; when the brick surface is polluted by water or oil stains, when a foot contacts with the brick surface, a vacuum adsorption effect is generated, a better road holding force is provided, and thus the anti-skid performance is strengthened.

Owner:DONGGUAN TIRESEALANT AUTO TECH

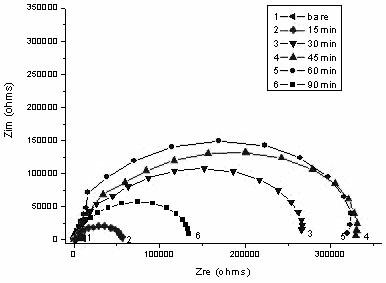

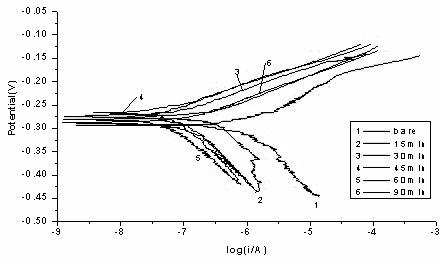

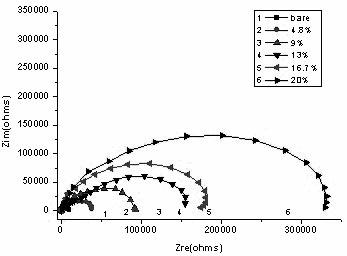

A kind of preparation method of cupronickel b30 with superhydrophobic surface of corrosion inhibition performance

InactiveCN102268662AAchieve anti-corrosion effectMetallic material coating processesSuperhydrophobeMetallurgy

The invention discloses a preparation method of cupronickel B30 with super-hydrophobic surface with corrosion inhibition performance. , and finally obtained a superhydrophobic surface of cupronickel B30 with corrosion inhibition properties. The obtained superhydrophobic surface of cupronickel B30 with corrosion inhibition performance has a contact angle of 152.8° and a corrosion inhibition efficiency of 96.1%.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

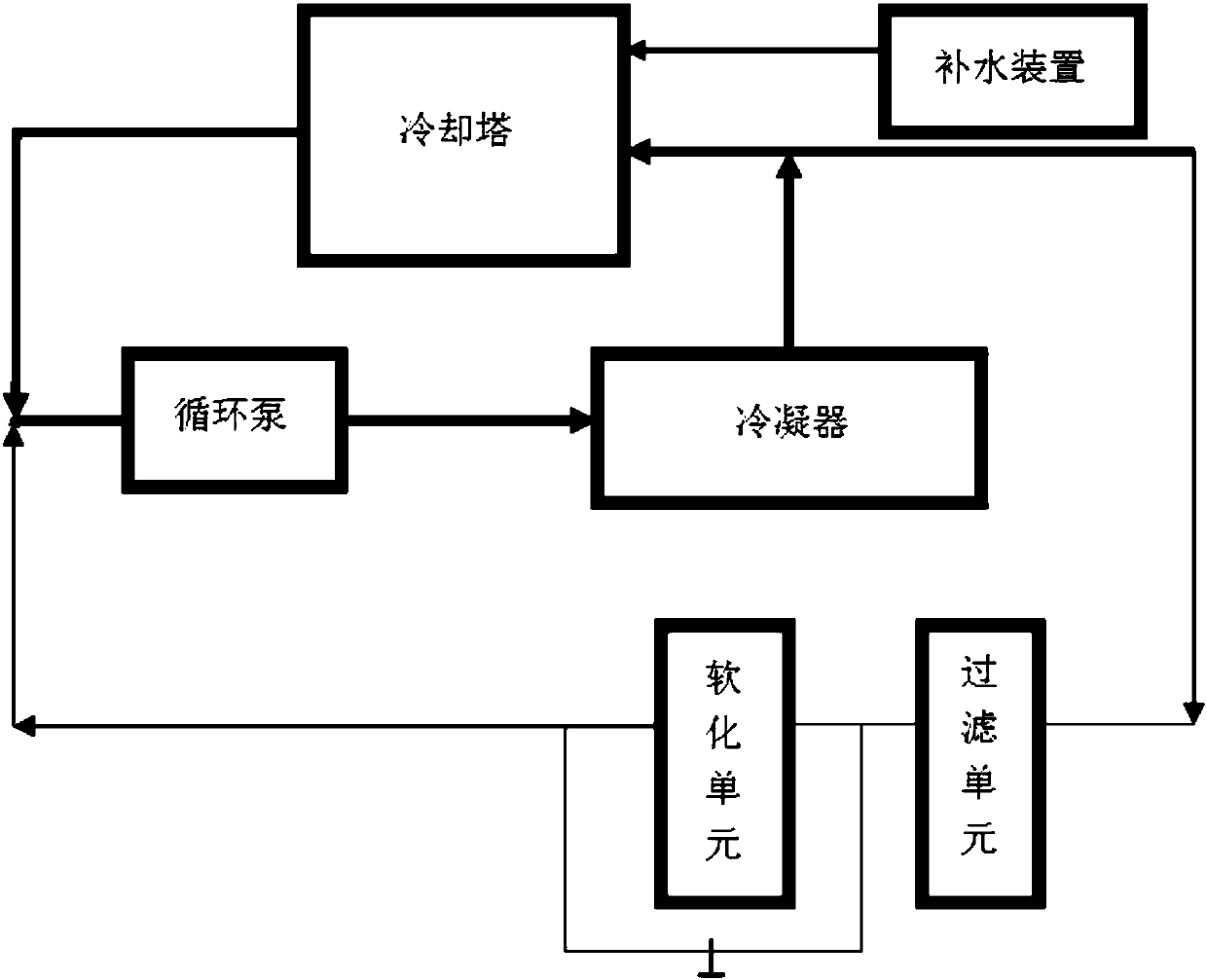

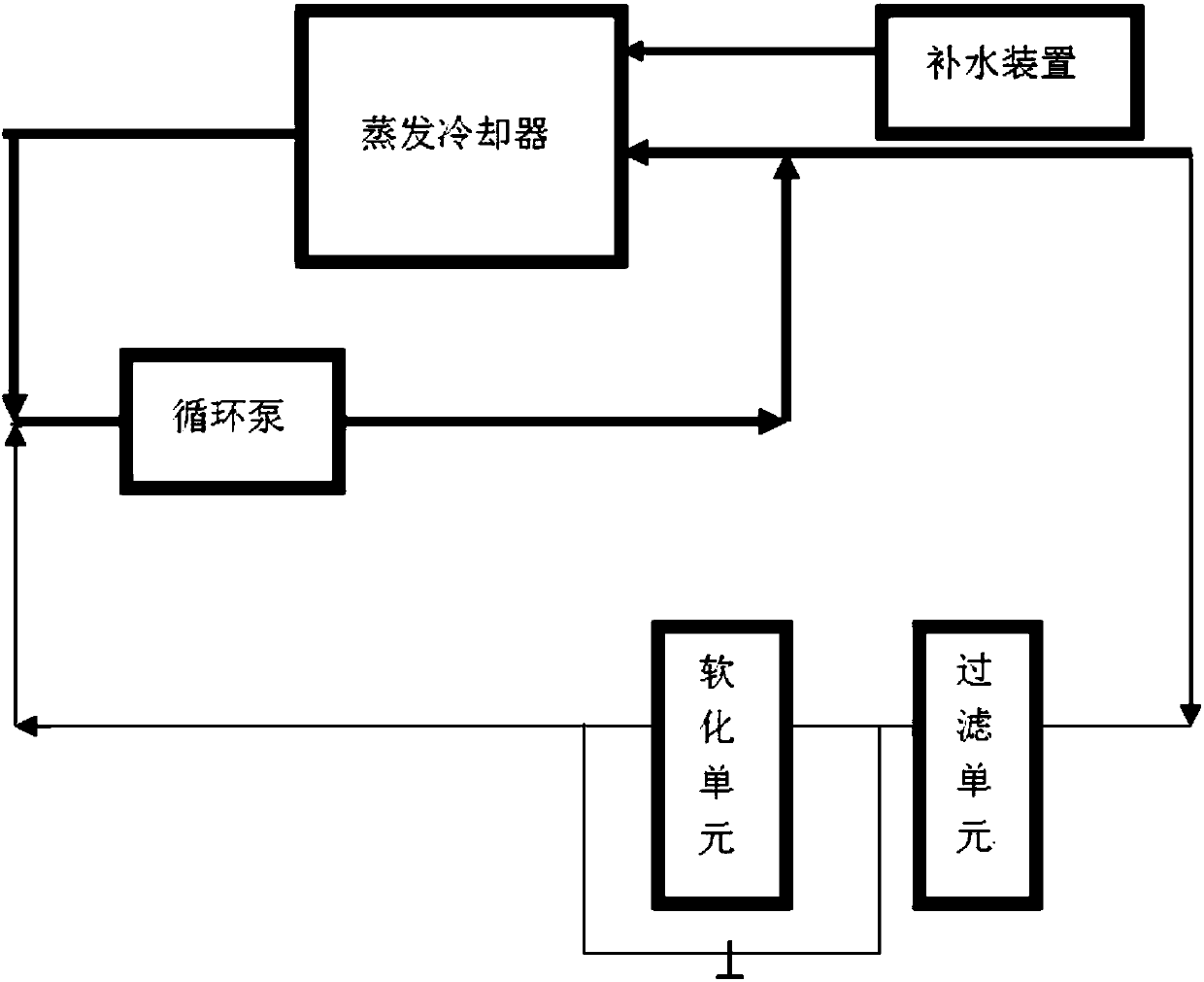

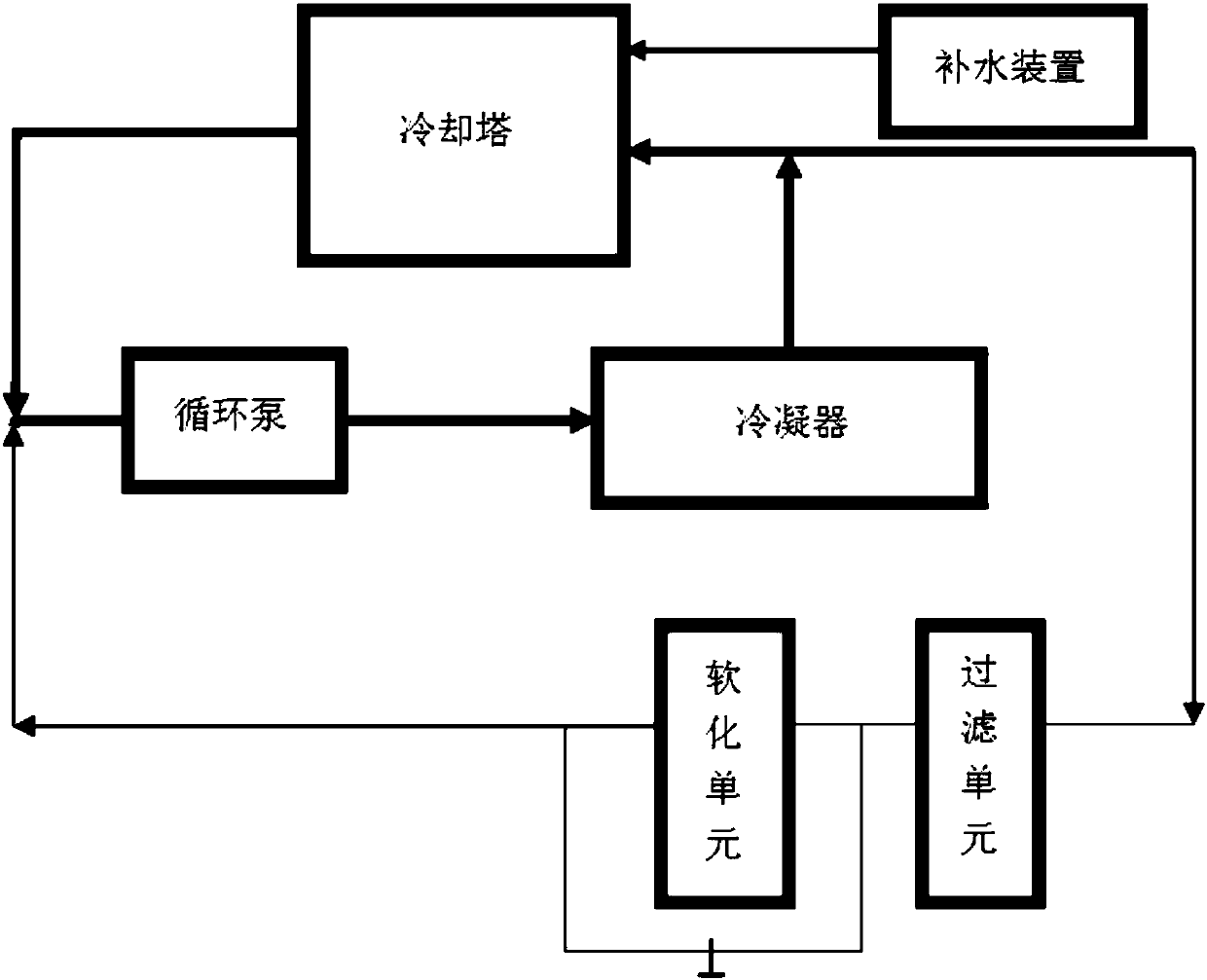

Ultrahigh-concentration-multiple circulating cooling water treatment system and circulating cooling water treatment method

InactiveCN106698774ASolve the special requirements of water qualitySolve the rise of thermal resistanceTreatment involving filtrationWater/sewage treatment by ion-exchangeWater savingWater treatment system

The invention discloses an ultrahigh-concentration-multiple circulating cooling water treatment system. The ultrahigh-concentration-multiple circulating cooling water treatment system comprises a circulating cooling water system and a bypath treatment system which is circularly connected with the circulating cooling water system, wherein the bypath treatment system comprises a filtering unit and a softening unit which are connected in sequence. The invention discloses a circulating cooling water treatment method. The circulating cooling water treatment method comprises the following steps: (1) concentrating circulating cooling water into ultrahigh-concentration-multiple circulating cooling water through the circulating cooling water system, wherein the concentration multiple reaches 20 to 1000 times; (2) filtering the ultrahigh-concentration-multiple circulating cooling water by adopting a bypass filtering method; and (3) softening the filtered ultrahigh-concentration-multiple circulating cooling water obtained by the step (2) by adopting an ion exchange method. According to the ultrahigh-concentration-multiple circulating cooling water treatment system and the circulating cooling water treatment method, the circulating cooling water is filtered and softened online through the bypath treatment system, and normal operation is realized under the condition of the ultrahigh-concentration-multiple circulating cooling water (with the concentration multiple of 20 to 1000 times); the water saving rate reaches 85 percent or more; and the corrosion prevention and microorganism inhibition effects, low cost, environment friendliness and feasibility are realized.

Owner:汪传发

Waterborne, colored, multifunctional, corrosion-resistant and waterproof coating

InactiveCN107201109AFunction increaseAchieve colorAnti-corrosive paintsMulticolor effect coatingsAcrylic resinMaterials science

The invention relates to waterborne, colored, multifunctional, corrosion-resistant and waterproof coating. The coating comprises a power material and a liquid material, wherein the powder material comprises, by weight, 5 parts of titanium dioxide, 10 parts of kaolin, 15 parts of talcum powder, 12 parts of mica powder, 7 parts of calcium carbonate, 3 parts of ceramic powder, 5 parts of glass powder, 4 parts of ground calcium carbonate, 4 parts of wollastonite powder and 3 parts of gelatin powder; the liquid material comprises, by weight, 5 parts of fluorocarbon resin, 4 parts of tert-carbonic acid, 3 parts of organic solvent, 10 parts of amino resin, 12 parts of crosslinking emulsion, 20 parts of acrylic resin, 3 parts of polyethylene, 20 parts of vinyl ester, 0.8 part of wetting agent, 0.4 part of mercaptopropionic acid, 0.6 part of diluent, 1.2 parts of levelling agent, 1.6 parts of film-forming auxiliaries, 0.9 part of thickening agent and 0.6 part of dispersing agent. By the coordination of the powder material and the liquid material, the coating is diversified in function, colored, resistant to corrosion, waterproof and multifunctional.

Owner:魏仲兴

Process for realizing corrosion prevention and mirror surface during coating of aluminum alloy wheels

The invention belongs to the technical field of coating, and relates to aluminum alloy wheel coating, in particular to a process for realizing corrosion prevention and mirror surface during coating ofaluminum alloy wheels. The process comprises the following steps of pretreating the wheels, making the wheels enter a coating line, spraying bottom powder on the surfaces of the wheels, spraying priming paint and carrying out leveling, spraying colored paint, and then carrying out leveling and curing; spraying transparent powder, and then carrying out high-temperature curing; finish-turning the surfaces of the wheels, and machining the surfaces to be polished according to a mirror surface process; putting the wheels into a polishing machine for sequential rough polishing and fine polishing; and carrying out cleaning, spraying the transparent powder, and then carrying out curing to obtain products. The method disclosed by the invention is simple in process, does not need adjustment of theprocess of a production line, and does not increase too much cost. The products prepared through the method has the advantages that sharp corners of various parts after the polishing are all polishedoff, so that the sharp corners are smooth and flat, the adhesion of oil paint is easy, the film thickness can be increased, and therefore, the anti-corrosion effect is achieved. The polished surface has a fine mirror surface effect, the image of an object can be clearly seen on the surfaces of the wheels, the surface is like a mirror, and the appearance is more attractive.

Owner:DARE WHEEL MFG

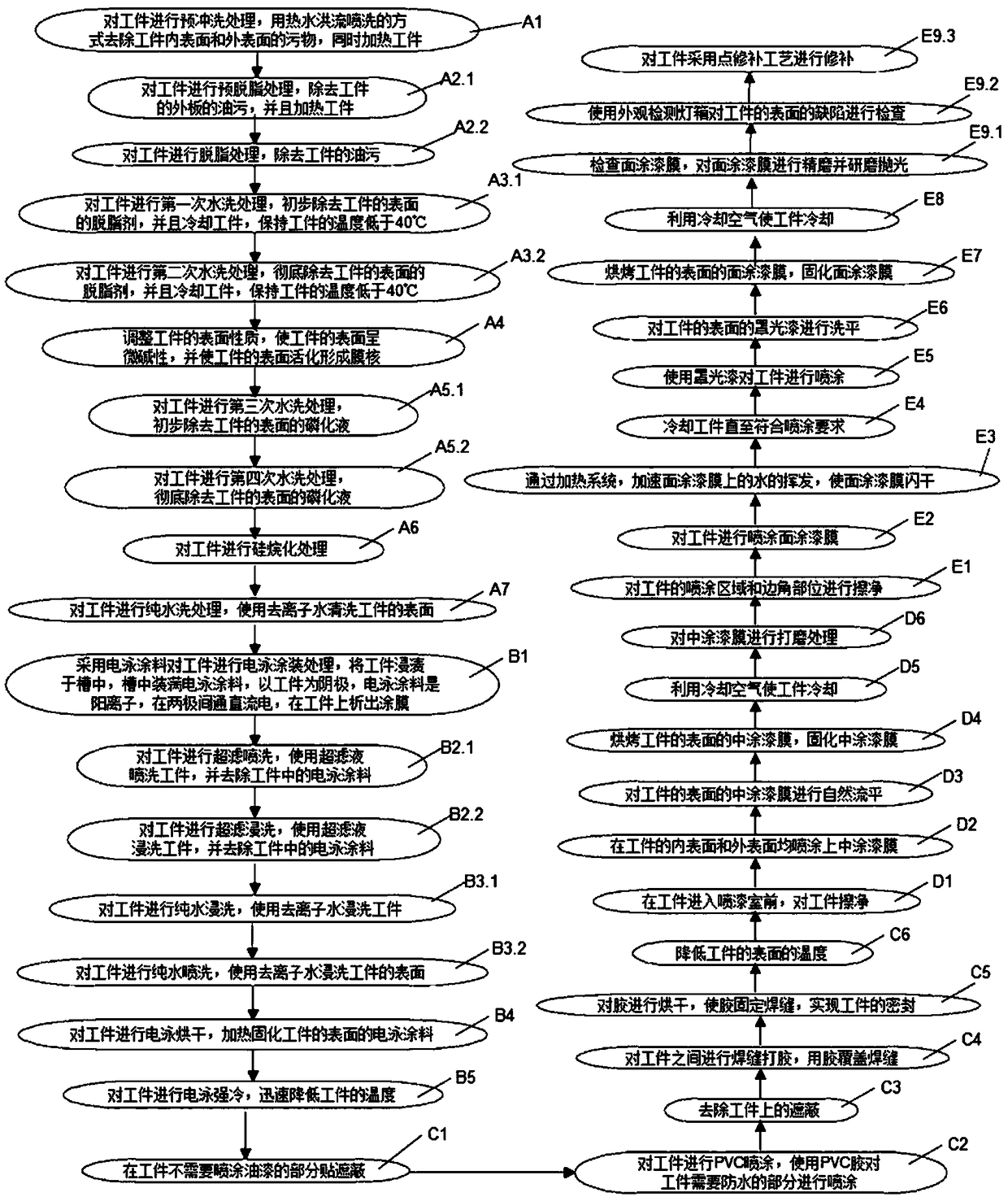

Process method of coating line

InactiveCN109482446AAchieve anti-corrosion effectPretreated surfacesElectrophoretic coatingsElectrophoresisWeld seam

The invention discloses a process method of a coating line. The process method comprises a fore-treatment process, an electrophoresis process, a pretreatment process, a middle coating process and a finish paint process which are operated in sequence, wherein the fore-treatment process comprises the following steps of pre-washing, degreasing, water washing, surface adjusting, water washing, silanization and pure water washing treatment; the electrophoresis process comprises the following steps of cathode electrophoresis, secondary electrophoresis, ultrafiltration spray washing, ultrafiltrationimmersion washing, the pure water washing, electrophoresis drying, electrophoresis strong cooling, checking and finishing; the pretreatment process comprises the following steps of pasting shielding,spraying PVC, shielding removing, welding seam and gluing, glue drying and glue strong cooling treatment; the middle coating process comprises the following steps of middle coating wiping, middle coating paint spraying, middle coating flash off, middle coating drying, middle coating strong cooling and middle coating grinding treatment; the finish paint process comprises the following steps of finish paint wiping, finish paint spraying, finish paint flash off, finish paint strong cooling, finishing varnish spraying, finishing varnish, finishing varnish washing, finish paint strong cooling and overhauling. According to the method, air and corrosion substances such as water and the like can be prevented from being attached to the surface of an automobile, so that the surface of the automobileis enabled to have an anti-corrosion effect.

Owner:NANTONG BEST MACHINE CO LTD

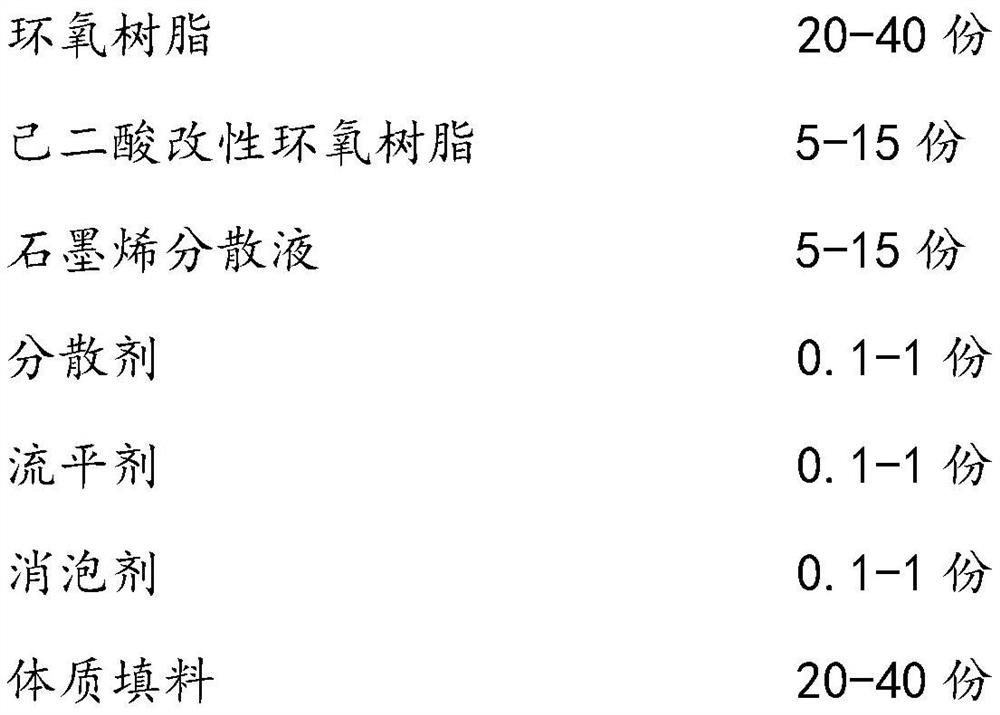

Long-acting anti-corrosion solvent-free universal epoxy coating and preparation method thereof

ActiveCN112029382AImprove cure rateLong application periodAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to the technical field of anti-corrosion coatings, and particularly relates to a long-acting anti-corrosion solvent-free universal epoxy coating and a preparation method thereof.The long-acting anti-corrosion solvent-free universal epoxy coating comprises a first component and a second component, wherein the first component comprises epoxy resin, adipic acid modified epoxy resin and graphene dispersion liquid; and the second component comprises an amine mixed curing agent and an amino silane coupling agent. The coating provided by the invention effectively solves the problems of large internal stress, poor coating flexibility and corrosion resistance, easiness in oil surface and gloss loss in a low-temperature environment and a high-humidity environment and the likeof an existing solvent-free epoxy coating system, has excellent corrosion resistance, good recoatability, excellent matching performance with various finishing paints, good weather resistance and thelike, has good film-forming property in low-temperature and high-humidity environments, has no oil surface or gloss loss, and achieves the technical goals of universality of the whole ship and universality in four seasons.

Owner:XIAMEN SUNRUI SHIP COATING

Loudspeaker with damping function

InactiveCN107659880AImprove sound qualityReduce noiseElectrical transducersLoudspeakersDamping functionEngineering

The invention discloses a loudspeaker with a damping function. The loudspeaker comprises a shell, a basket and an underframe, wherein the shell is a circular truncated cone shape, and the internal ofthe shell is in a cavity state; the upper bottom surface of the shell is in a through state, and the lower bottom surface of the shell is in a sealing state; the underframe is formed by two cylinderswhich are called as a first cylinder and a second cylinder; the section area of the first cylinder is greater than that of the second cylinder, and the second cylinder is located at the center of thefirst cylinder, and penetrates the first cylinder; the internal of the second cylinder is in a hollow state; a vibrating diaphragm, a dustproof cover, a spider, a voice coil and a permanent magnet arearranged in the shell; a damping device is arranged at the top of the shell, and one connection is formed between the damping device at the top of the shell and the basket and the underframe, and theunoccupied parts of the internal edge and bottom of the shell are filled with a damping material. The invention provides a loudspeaker capable of achieving the damping effect.

Owner:温州华大信息技术有限公司

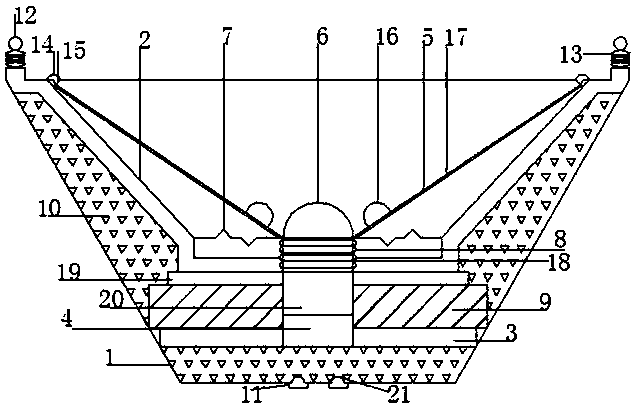

Climbing apparatus

The invention discloses a climbing apparatus which comprises a lower platform, an upper platform and a control device. The lower platform is used for being clamped to the outer side of a tower drum. The lower platform is provided with a first clamping degree adjusting device used for adjusting the clamping degree of the lower platform. The upper platform is used for being clamped to the outer side of the tower drum and provided with a second clamping degree adjusting device used for adjusting the clamping degree of the upper platform. One of the upper platform and the lower platform is connected with a lifting rod, and the other one of the upper platform and the lower platform is arranged on the lifting rod in a slidable mode and is provided with a height adjusting device used for adjusting and fixing the relative position of the height adjusting device and the lifting rod. The control device is used for controlling the first clamping degree adjusting device, the second clamping degree adjusting device and the height adjusting device. The climbing apparatus used for automatic climbing can automatically climb a wind driven generator tower drum or a similar building and can achieve automatic cleaning and corrosion resistance for the building if being provided with an automatic cleaning or rust removal spraying system, labor is saved, the efficiency is improved, and the safety of an operator and the tower drum is ensured.

Owner:CHONGQING HAIZHUANG WINDPOWER ENG CO LTD

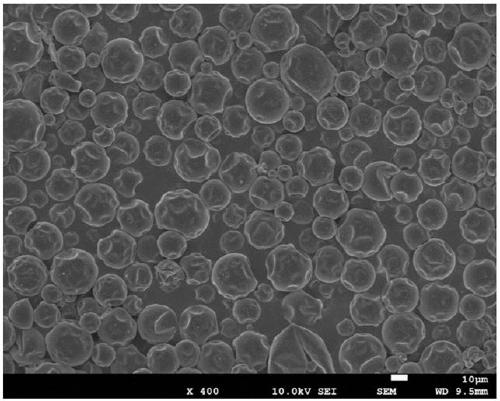

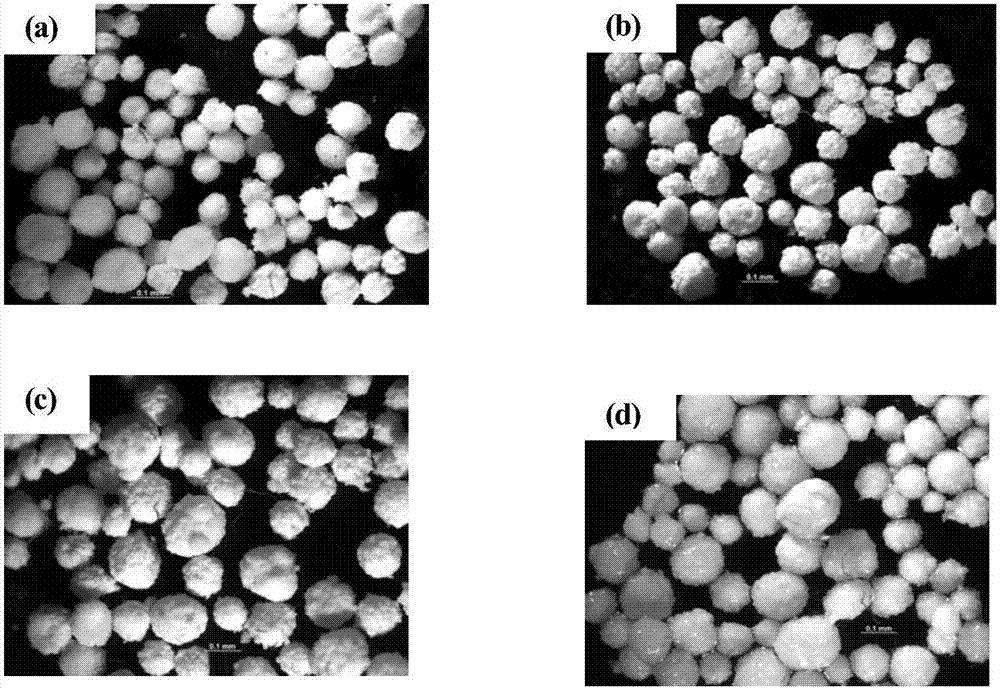

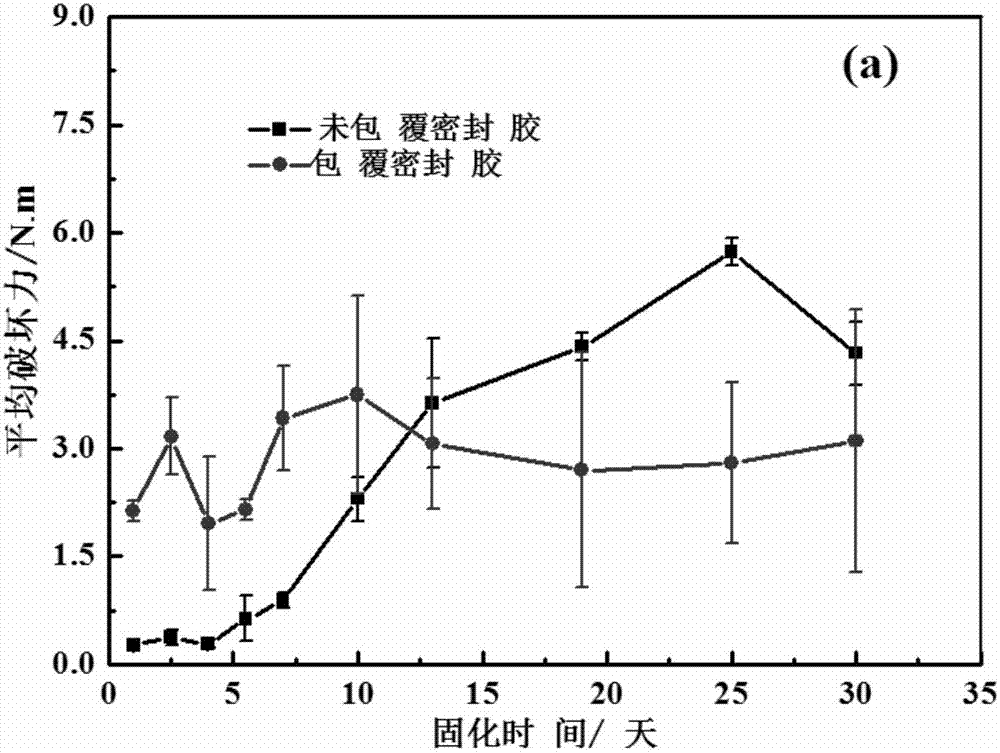

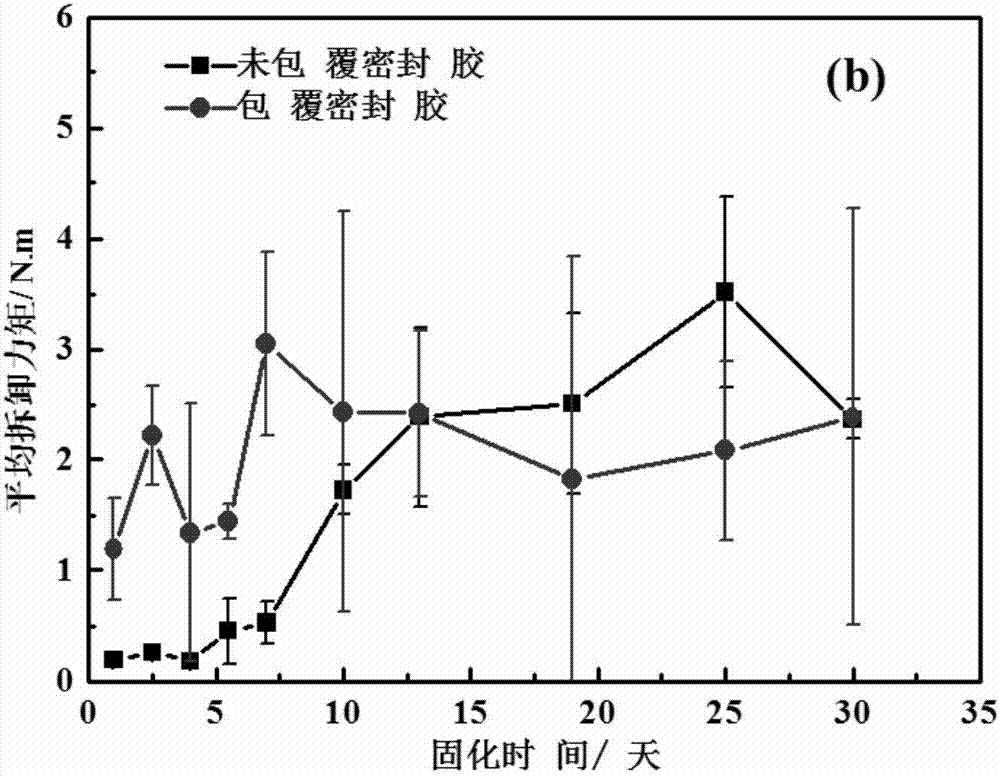

Polysulfide sealant microcapsule as well as preparation method and application thereof

InactiveCN106978131AAchieve sealingRealize anti-looseningNon-macromolecular adhesive additivesOther chemical processesIn situ polymerizationFiltration

The invention discloses a polysulfide sealant microcapsule as well as a preparation method and application thereof, belonging to the technical field of sealing and corrosion prevention. The preparation method comprises the steps of reacting by virtue of urea and formaldehyde under a low-temperature continuous stirring condition for 6-24 hours by virtue of an in situ polymerization method, and sequentially carrying out distilled water washing, vacuum filtration and room temperature drying on a product, so as to obtain the polysulfide sealant microcapsule. The particle size of the prepared polysulfide sealant microcapsule is 80-150 microns, the microcapsule is of a relatively regular sphere shape, has a relatively rough surface and is good in monodispersity, the coating amount of a sealant is relatively high, and the sealant does not denature after being placed at the room temperature for a long time. The preparation method has the beneficial effects that preparation conditions are mild, the operation is simple, and equipment requirements are low; and the prepared polysulfide sealant microcapsule can be widely applied to pre-coating of sealed screws and rivets and other parts required to be sealed through extrusion and has wide application prospects in the industrial fields of automobiles, aerospace, ships, petrochemical industry, electric instruments and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

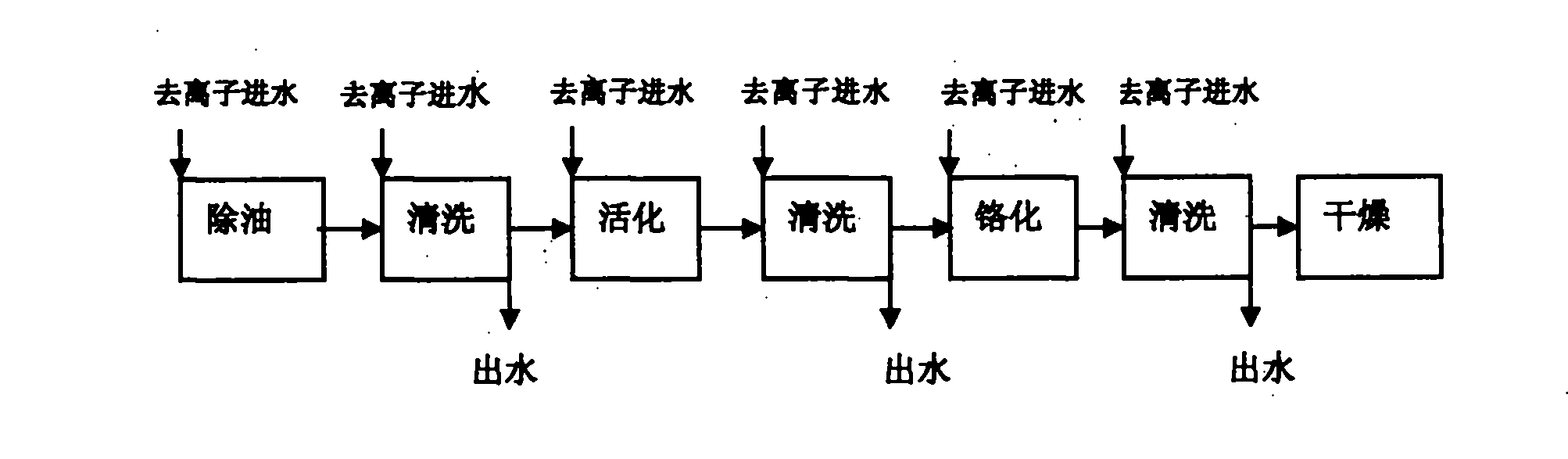

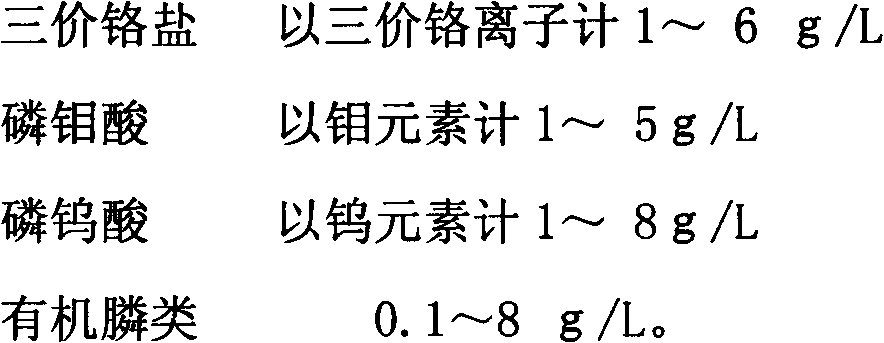

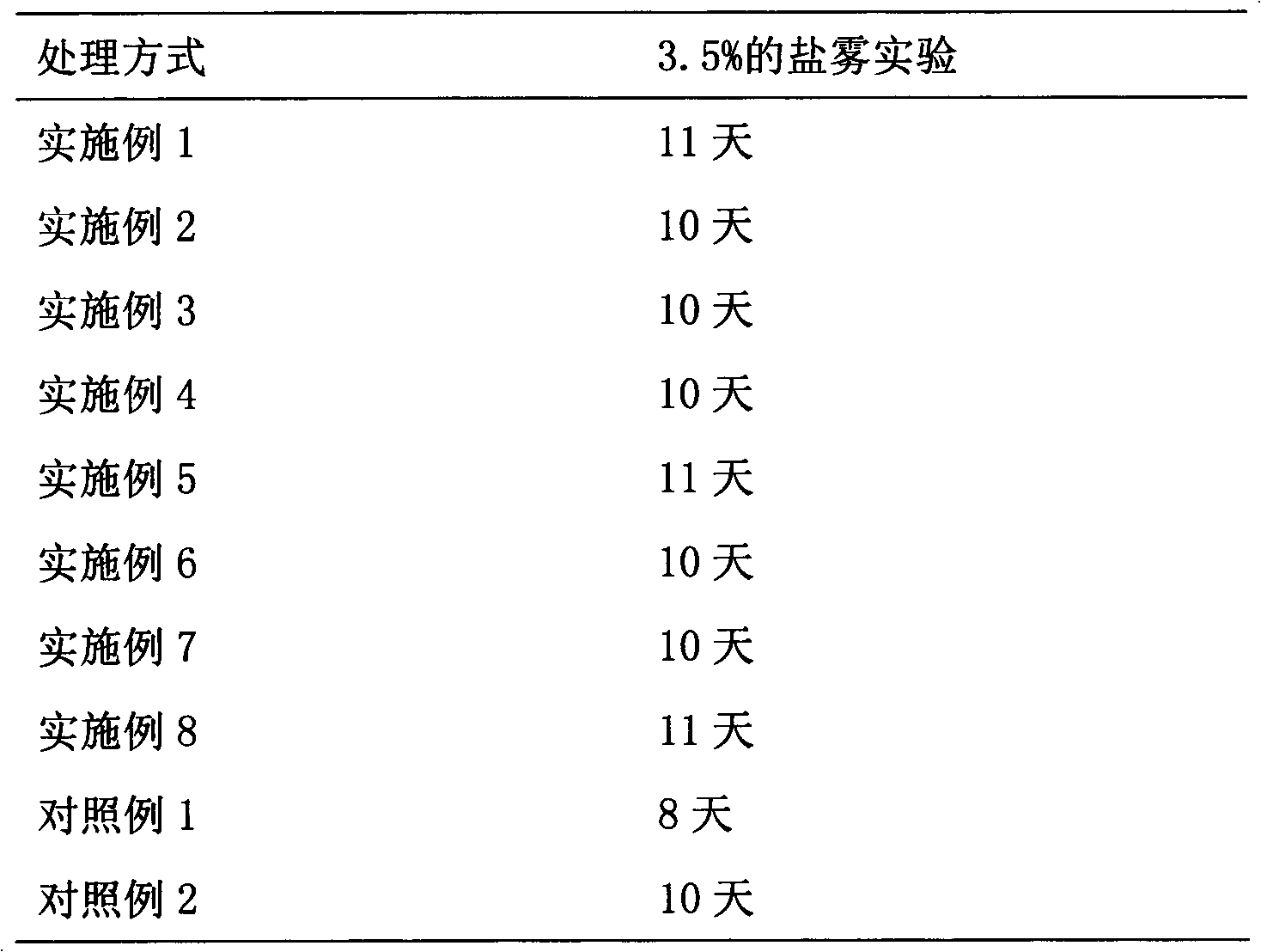

Preparation method and film-forming liquid for aluminum alloy high-performance trivalent chromium hybrid conversion film

InactiveCN102534598AImprove corrosion resistanceAchieve anti-corrosion effectMetallic material coating processesChemical conversionHexavalent chromium

The invention discloses a preparation method and film-forming liquid for an aluminum alloy high-performance trivalent chromium hybrid conversion film. The film-forming liquid is added with phosphotungstate serving as an inorganic corrosion inhibitor, and organophosphorus; and when an aluminum or aluminum alloy workpiece is treated by the film-forming liquid, a trivalent chromium, phosphotungstate and organophosphorus hybrid conversion film can be formed on the surface of an aluminum alloy. Compared with a single trivalent chromium conversion film, the hybrid conversion film can improve the corrosion resistance of the aluminum alloy and achieve the anti-corrosion effect of a hexavalent chromium chemical conversion film.

Owner:GUANGXI UNIV FOR NATITIES

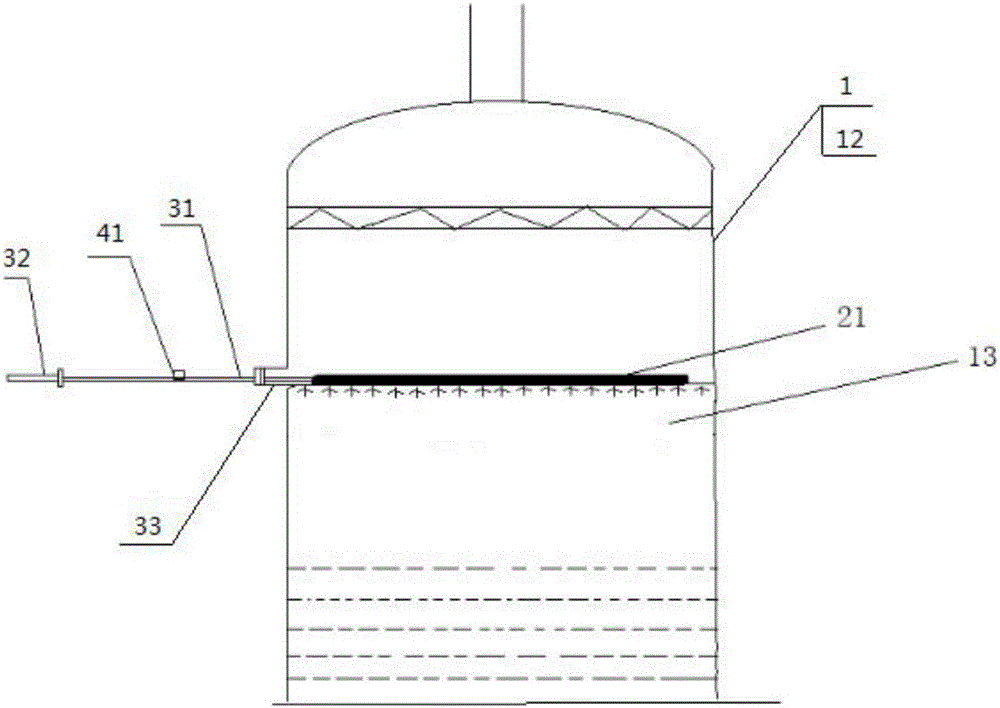

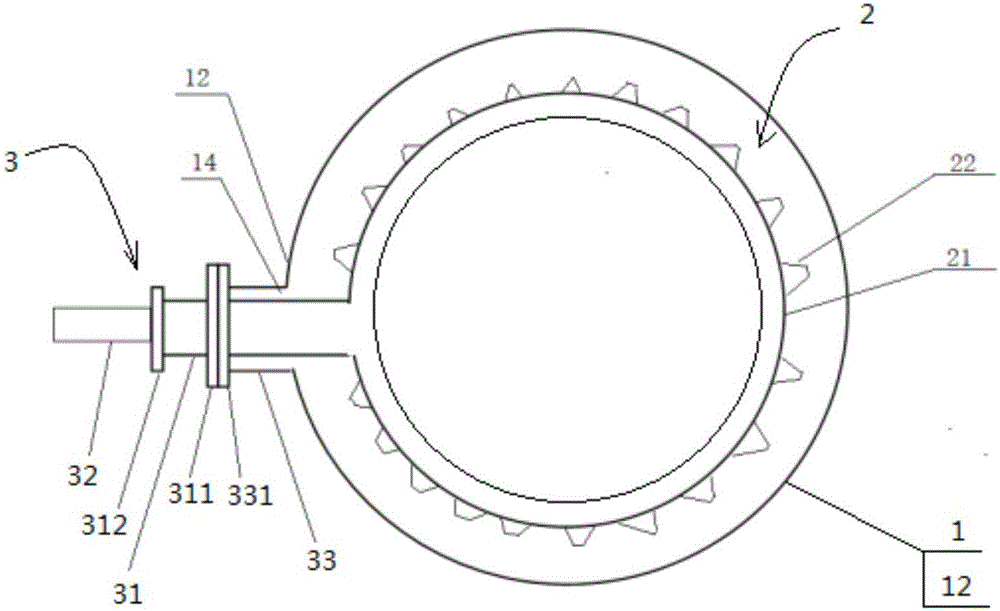

Desulfurizing absorption tower wall cleaning device

InactiveCN106693649AAvoid damageIncrease the spray areaGas treatmentHollow article cleaningWater supplyTower

The invention discloses a desulfurizing absorption tower wall cleaning device. The device comprises a water spray device, a water supply device connected with the water spray device and a water supply control device, wherein the water spray device is arranged at the top of a washing concentration section arranged in a desulfurizing absorption tower and comprises a circular pipe and a plurality of water spray nozzles, the circular pipe extends along the circumference of the inner wall of the desulfurizing absorption tower, and the water spray nozzles are arranged on the circular pipe, communicated with the circular pipe and used for spraying water to the inner wall of the desulfurization absorption tower; a through hole is formed in the wall of the desulfurizing absorption tower, the water supply device comprises a connecting pipe, one end of the connecting pipe penetrates the through hole to be communicated with the circular pipe, and the other end of the connecting pipe is used for being connected with a water supply pipe; the water supply control device comprises an electric valve arranged on the water supply pipe and a controller which is connected with the electric valve to control the opening and closing of the electric valve. The invention provides the desulfurizing absorption tower wall cleaning device capable of removing salt precipitated out of the tower wall and solves the technical problem of system shutdown caused by damage to equipment due to salt precipitated out of the desulfurizing absorption tower wall and hung to the wall.

Owner:NORTH HUAJIN CHEM IND CO LTD

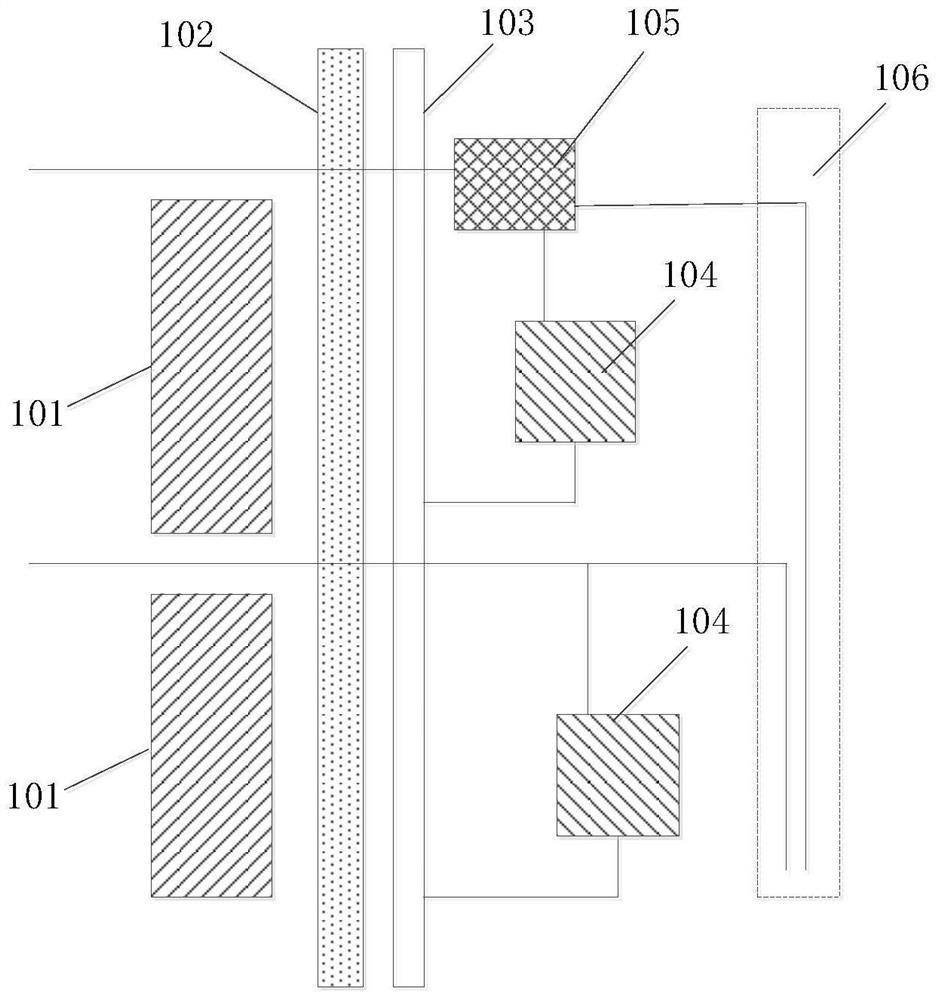

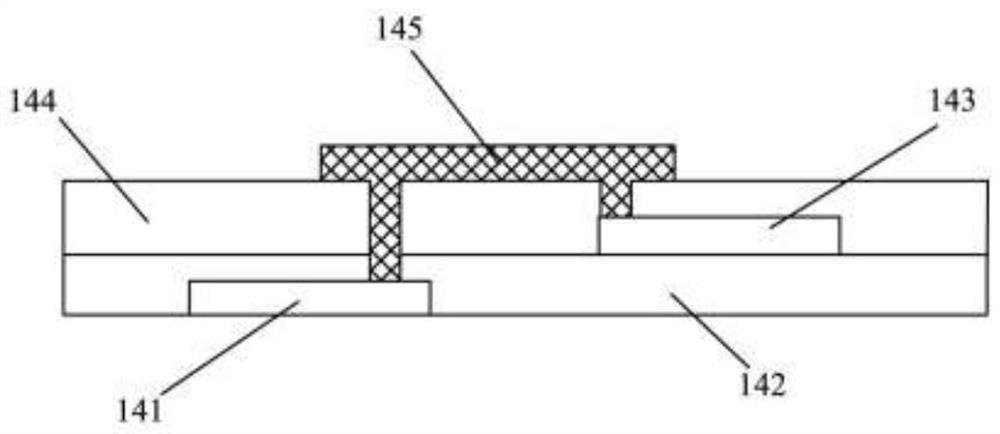

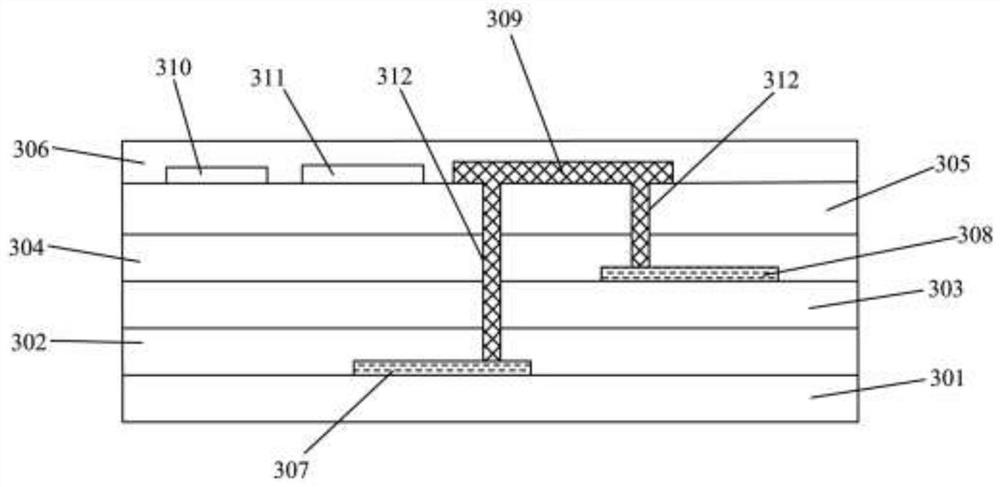

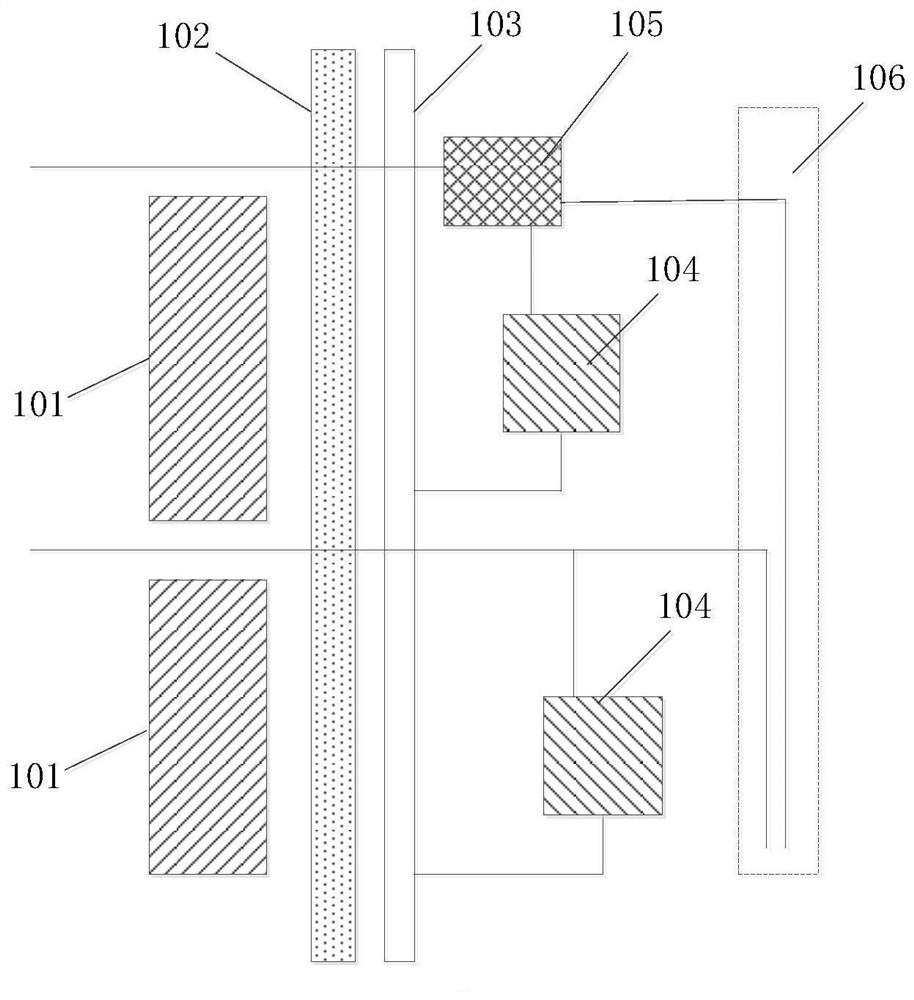

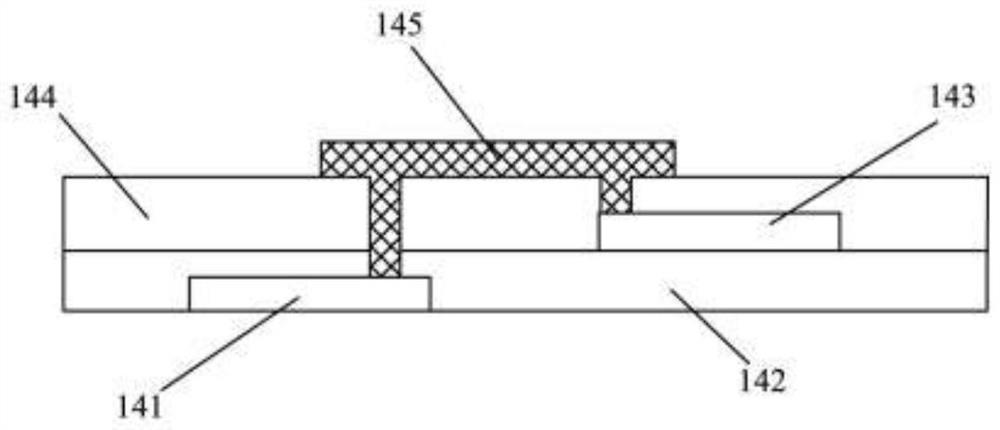

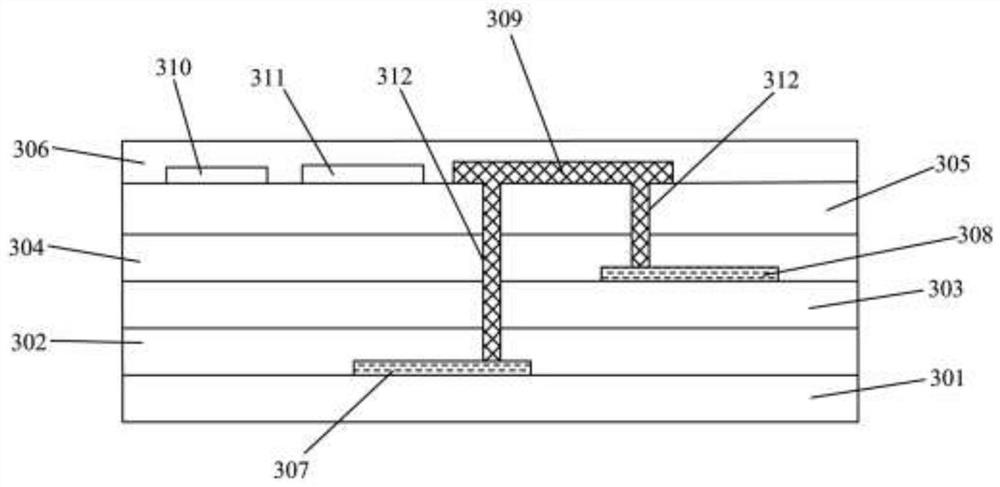

Display panel and display device

ActiveCN111736395AExtended service lifeCorrosion is notStatic indicating devicesNon-linear opticsDisplay deviceElectrical connection

The invention discloses a display panel and a display device, and the display panel comprises a substrate, a first electrode layer, a first insulating layer, a second electrode layer, a second insulating layer, a third electrode layer, a first gate line, a second gate line, a line-changing connection block, a common electrode line, and a first low-potential gasket, wherein the first electrode layer, the first insulating layer, the second electrode layer, the second insulating layer and the third electrode layer are located on the substrate in order, the first electrode layer comprises a firstgate line, the second electrode layer comprises a second gate line, the third electrode layer comprises a line changing connecting block, a first low-potential liner and a common potential line, and the line-changing connection block is electrically connected with the first gate line and the second gate line through via holes respectively; at least part of the first low-potential liner is locatedbetween the line-changing connection block and the common potential line, and the potential of the first low-potential liner is lower than the potential of the common potential line and lower than thelowest potential of the line-changing connection block. According to the invention, the line-changing connection block area in the display panel can be protected from being corroded.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Anticorrosive paint for door and preparation method thereof

InactiveCN106318133ASolution to short lifeDissolution inhibitionFireproof paintsAnti-corrosive paintsEpoxyAcrylic resin

The invention discloses an anticorrosive paint for a door. The anticorrosive paint is prepared from the following materials in parts by weight: 35-40 parts of barium hydroxide, 20-25 parts of zinc oxide, 15-20 parts of aluminium naphthenate, 7-9 parts of barium chromate, 22-24 parts of ceramic micro-powder, 9-15 parts of silicon carbide, 50-55 parts of novolac epoxy resin, 3-5 parts of aluminium phosphate, 7-10 parts of polyvinyl butyral, 6-9 parts of butadiene resin film former, 4-8 parts of acrylic resin, 2-5 parts of mica, 3-8 parts of inositol hexaphosphate, 12-14 parts of chlorinated paraffin, 8-9 parts of toluenesulfonic acid, 6-8 parts of lithopone, 11-14 parts of biuret, 22-26 parts of polysiloxane, 8-10 parts of boiled wood oil, and 16-21 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate. The anticorrosive paint for the door has good anticorrosion performance, is resistant to high temperature, has an insulating effect, and can keep long life of the coating.

Owner:ANHUI KATA DOOR & WINDOW

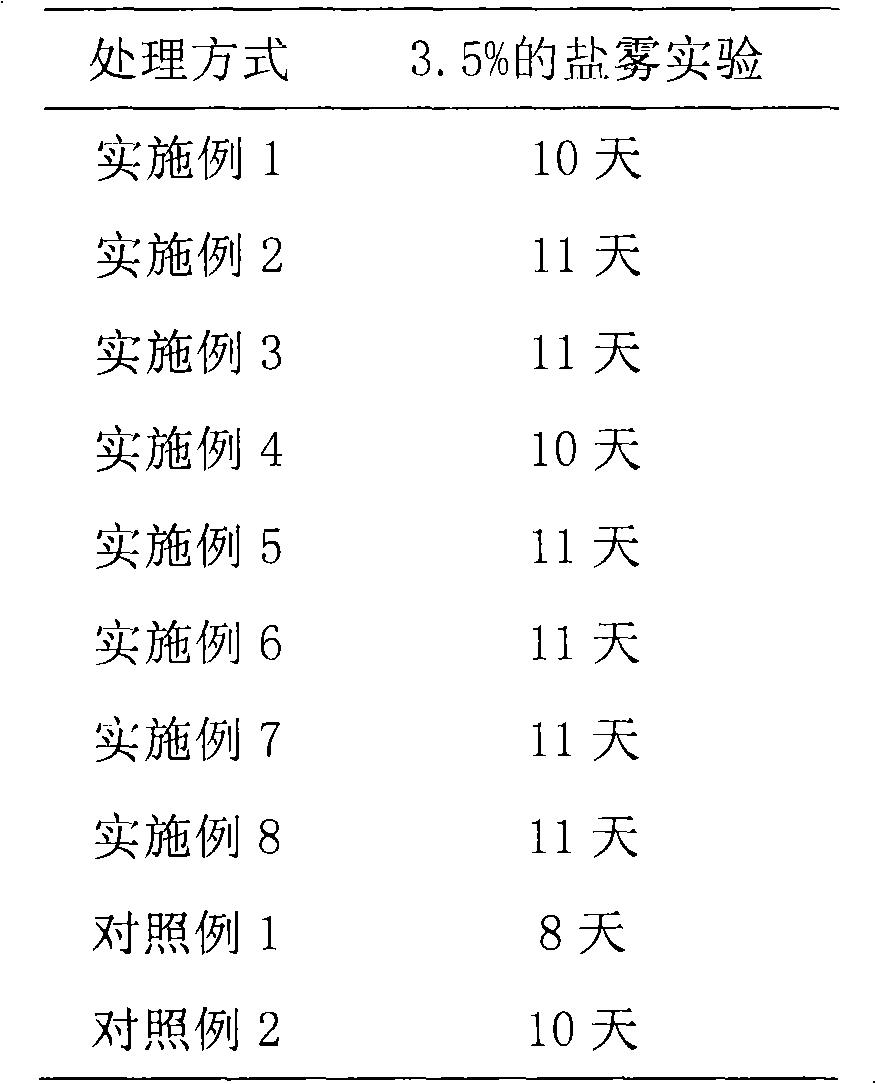

Preparation method of aluminum alloy trivalent chromium hybridization conversion film and film-forming liquid thereof

InactiveCN102304707AImprove corrosion resistanceAchieve anti-corrosion effectMetallic material coating processesEthanolaminesCobalt salt

The invention discloses a preparation method of an aluminum alloy trivalent chromium hybridization conversion film and film-forming liquid thereof. Bivalent cobalt salt used as an inorganic corrosion inhibitor and ethanolamine used as an organic corrosion inhibitor are added into the film-forming liquid, and the obtained film-forming liquid is used to treat an aluminum or aluminum alloy workpiece to form a trivalent chromium hybridization conversion film on the surface of the aluminum alloy. Compared with the single trivalent chromium conversion film, by adopting the aluminum alloy trivalent chromium hybridization conversion film provided by the invention, the corrosion resistance of the aluminum alloy can be improved, and the corrosion resistant effect of the hexavalent chromium chemical conversion film can be realized.

Owner:GUANGXI UNIV FOR NATITIES

A kind of strong corrosion-resistant galvanized steel strand and its manufacturing method

InactiveCN104451434BImprove corrosion resistanceImprove toughnessTextile cablesImpurityCorrosion resistant

The invention discloses a galvanized steel strand with strong corrosion resistance. The weight percentages of the components are: C: 0.83-0.85%, Mn: 0.76-0.78%, Si: 0.09-0.13%, Cr: 0.53-0.55 %, Mo: 0.16‑0.18%, Ni: 0.41‑0.43%, V: 0.015‑0.025%, B: 0.003‑0.005%, P≤0.015%, S≤0.012%, Cu≤0.17%, N≤0.005%, The rest is Fe and unavoidable impurities; the invention also discloses a method for manufacturing a strong corrosion-resistant galvanized steel strand; the product of the invention has strong corrosion resistance, high fatigue resistance, and high purity of wire steel , uniform composition and structure, long service life.

Owner:ROLLAS POWER TECH CO LTD

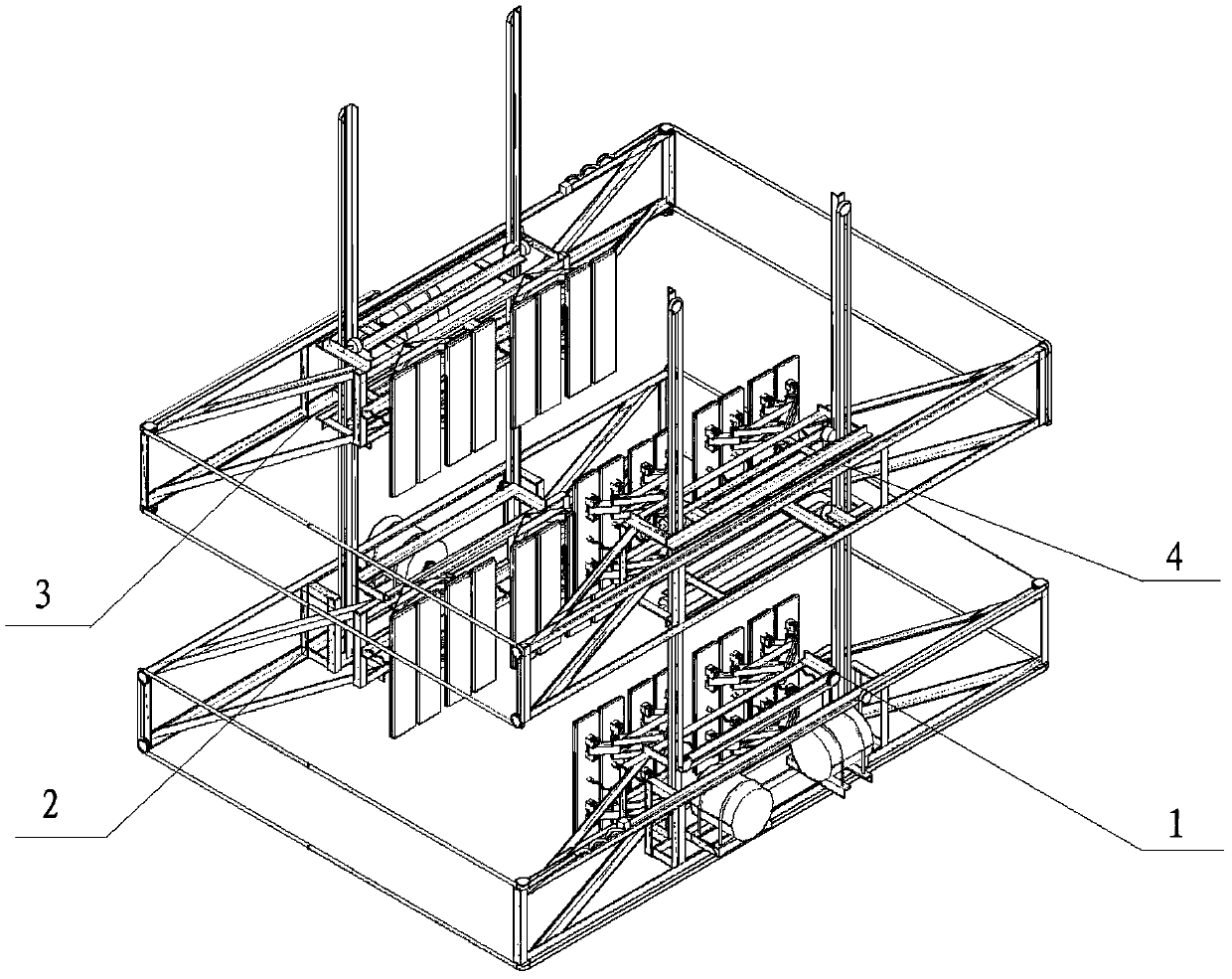

Efficient alloy workpiece surface corrosion prevention device

ActiveCN111841945AAchieve teleportationAchieve anti-corrosion effectSpraying apparatusAlloyElectronic component

The invention relates to an efficient alloy workpiece surface corrosion prevention device which comprises a base, supporting rods, a cross rod, a conveying mechanism and a corrosion preventing mechanism. The cross rods are arranged above the base through the supporting rods, and the conveying mechanism is arranged above the baes. The corrosion preventing mechanism is arranged above the conveying mechanism, and comprises a limiting assembly and a liquid spraying assembly. According to the efficient alloy workpiece surface corrosion prevention device, conveying of workpieces is achieved throughthe conveying mechanism, and corrosion prevention of the workpieces is achieved through the corrosion preventing mechanism; compared with an existing corrosion preventing device, conveying and corrosion prevention of the workpieces are achieved at the same time through one output end, and energy is saved; pure mechanical linkage is adopted by the conveying mechanism and the corrosion preventing mechanism, use of a sensor and other electronic elements is avoided, and therefore the stability of the device is improved, and the service life of the device is prolonged; and compared with an existingcorrosion preventing mechanism, the workpieces of different sizes can be subjected to corrosion preventing operation through the corrosion preventing mechanism, the practicality is improved, the spraying amount can be improved, and waste of a corrosion remover is avoided.

Owner:南京江宁区上峰国银标准件厂

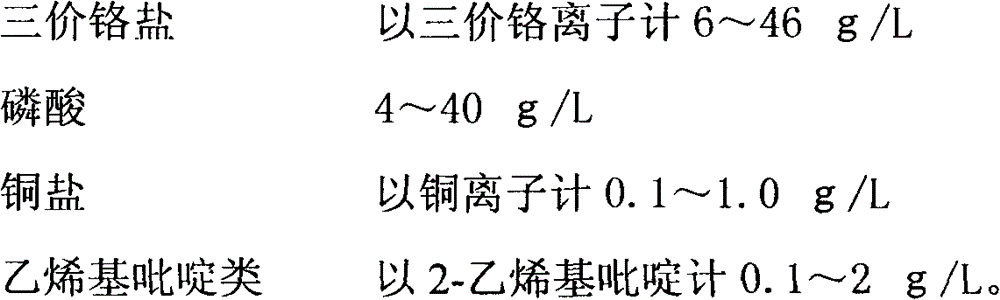

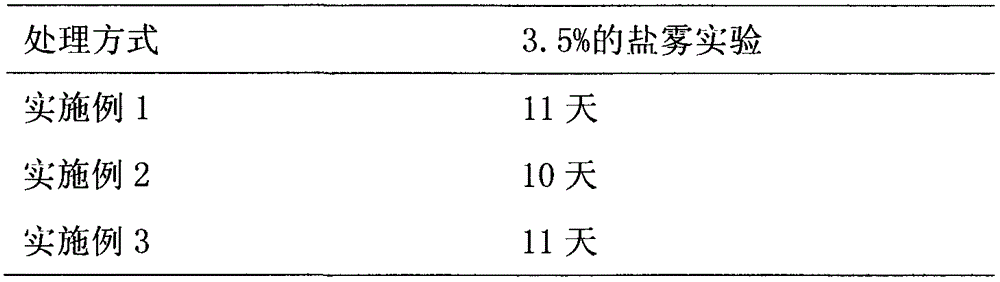

Method of preparing aluminum alloy dark green trivalent chromium conversion film and film-forming liquid thereof

InactiveCN102912336AGood colorImprove corrosion resistanceMetallic material coating processesVinyl pyridineChemical conversion

The invention discloses a method of preparing an aluminum alloy dark green trivalent chromium conversion film and film-forming liquid thereof. The method comprises the following steps: adding copper salt and organic vinyl pyridines in the film-forming liquid; and using the film-forming liquid to process aluminum or aluminum alloy workpieces so that a dark green trivalent chromium conversion film can be formed on the surface of the aluminum alloy. Compared with a trivalent chromium conversion film with a single film layer, the application of the aluminum alloy dark green trivalent chromium conversion film can satisfy the requirement on dark green color tone, the anti-corrosion performance of the aluminum alloy is improved, and the anti-corrosion effect of a hexavalent chromium chemical conversion film can be achieved.

Owner:GUANGXI UNIV FOR NATITIES

Display panel and display device

ActiveCN111736398AExtended service lifeCorrosion is notStatic indicating devicesNon-linear opticsDisplay deviceElectrical connection

The invention discloses a display panel and a display device, and the display panel comprises a substrate, a first electrode layer, a first insulating layer, a second electrode layer, a second insulating layer and a third electrode layer which are located on the substrate in order, a first gate line, a second gate line, a line-changing connection block, a common electrode line, and a first low-potential gasket, wherein the first electrode layer comprises a first gate line, the second electrode layer comprises a second gate line, the third electrode layer comprises a line changing connecting block, a first low-potential liner and a common potential line, and the line-changing connection block is electrically connected with the first gate line and the second gate line through via holes respectively; at least part of the first low-potential gasket is located between the line-changing connection block and the common electrode line, and the potential of the first low-potential gasket is lower than the potential of the common electrode line and lower than the lowest potential of the line-changing connection block. According to the invention, the line-changing connection block area in thedisplay panel can be protected from being corroded.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

A kind of preparation method of gray aluminum alloy trivalent chromium composite conversion film and its film-forming solution

InactiveCN102286738AGood colorImprove corrosion resistanceMetallic material coating processesComposite filmCobalt salt

The invention discloses a method for preparing a gray aluminum alloy trivalent chromium conversion film and its film-forming solution. In the film-forming solution, an inorganic corrosion inhibitor divalent cobalt salt and an organic corrosion inhibitor ethanolamine are added. The film-forming solution is used to Liquid treatment of aluminum or aluminum alloy workpieces can form a gray trivalent chromium conversion film on the surface of the aluminum alloy. Compared with the trivalent chromium conversion film with a single film layer, the present invention can meet customers' requirements for gray tone, improve the anticorrosion performance of aluminum alloy, and achieve the anticorrosion effect of hexavalent chromium chemical conversion film.

Owner:GUANGXI UNIV FOR NATITIES

Technological method for thermal shaping clean production of light alloy die casting and product

The invention relates to a technological method for thermal shaping clean production of a light alloy die casting and a product. The technological method for thermal shaping clean production of the light alloy die casting comprises the following steps of: 1, providing a cast light alloy die casting, and carrying out surface treatment, polishing, cleaning and drying on the cast light alloy die casting; 2, heating the light alloy die casting, and removing internal stress of the light alloy die casting; 3, alternately carrying out hot treatment and cold treatment on the light alloy die casting; 4, removing structures with non-appearance requirements from the surface of the light alloy die casting; and 5, spraying an anti-corrosion temperature-resistant protective layer to the surface of the light alloy die casting, and drying the anti-corrosion temperature-resistant protective layer. According to the technological method for thermal shaping clean production of the light alloy die castingand the product, as the light alloy die casting is treated through a plasma or chemical surface treating agent method first, no toxic effect exists, environment friendliness is achieved, and clean production is achieved; and thermal shaping treatment and cold shaping treatment are conducted alternately, the flatness is controlled to be within 0.02 mm, the protective layer is sprayed after the structures with non-appearance requirements are removed from the surface, and therefore, chemical corrosion resistance, high temperature resistance and the like are achieved.

Owner:FUJIA ELECTRONICS KUSN

Method for preparing trivalent chromium and phosphomolybdiumtungstic acid hybrid film on surface of aluminum alloy and film forming solution for method

InactiveCN102618861AImprove corrosion resistanceAchieve anti-corrosion effectMetallic material coating processesPhosphomolybdic acidMolybdic acid

The invention discloses a method for preparing a trivalent chromium and phosphomolybdiumtungstic acid hybrid film on the surface of aluminum alloy and a film forming solution for the method. Inorganic corrosion inhibitors, namely phosphomolybdic acid and phosphotungstic acid and amino trimethylene phosphonic acid or 1-hydroxyethane-1,1-diphosphonic acid or ethylene diamine tetra (methylene phosphonic acid) sodium corrosion inhibitors are added into the film forming solution; and when the film forming solution is used for treating an aluminum or aluminum alloy workpiece, a trivalent chromium, phosphomolybdic acid, phosphotungstic acid and amino trimethylene phosphonic acid or 1-hydroxyethane-1,1-diphosphonic acid or ethylene diamine tetra (methylene phosphonic acid) sodium hybrid film on the surface of the aluminum alloy. Compared with a single-layer trivalent chromium conversion film, the trivalent chromium and phosphomolybdiumtungstic acid hybrid film can improve the corrosion resistance of the aluminum alloy and can achieve the anticorrosion effect of a hexavalent chromium chemical conversion film.

Owner:GUANGXI UNIV FOR NATITIES

Anticorrosion and antifouling type coating resin and method for preparing same

ActiveCN108727545AGood anti-corrosion effectGood antifouling effectAntifouling/underwater paintsPaints with biocidesSurface energyEmulsion

The invention discloses anticorrosion and antifouling type coating resin and a method for preparing the same. The method includes adding vinylidene chloride, acrylate, cross-link emulsification monomers, latex protective agents, sodium hydrogen sulfite and water into a container, and uniformly stirring the vinylidene chloride, the acrylate, the cross-link emulsification monomers, the latex protective agents, the sodium hydrogen sulfite and the water to obtain mixed liquid A; mixing acrylic acid monosilane ester, cross-link emulsification monomers and water with one another to obtain mixed liquid B; adjusting the temperature of a reactor until the temperature of the reactor reaches 15-30 DEG C, adding ammonium persulfate and sodium hydrogen sulfite aqueous solution into the reactor in nitrogen atmosphere, dropwise adding the mixed liquid A into the reactor within 3-4 h, then continuing to dropwise add the mixed liquid B and initiators into the reactor for the dropwise adding time of 1-2h, and then keeping the temperature constant for 2-3 h to completely carry out reaction. The anticorrosion and antifouling type coating resin and the method have the advantages that high-stability and high-adhesion emulsion with low surface energy can be prepared from soap-free emulsion at the low temperature under the normal pressure by means of polymerization; the proportions of the vinylidenechloride, different types of acrylate, different types of acrylic acid silyl ester and the cross-link emulsification monomers are adjusted, the capacity such as the adhesion, the water resistance, theweather resistance, the salt resistance and the fouling organism avoidance of resin films can be regulated and controlled, and accordingly the comprehensive performance of anticorrosion and antifouling coating can be improved.

Owner:LUDONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com