Long-acting anti-corrosion solvent-free universal epoxy coating and preparation method thereof

An epoxy coating, long-term anti-corrosion technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of large internal stress in the system, easy oil surface, small molecular weight, etc., to increase the penetration distance, improve Dispersion effect, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention provides a kind of preparation method of long-acting anticorrosion solvent-free general-purpose epoxy paint, comprises the preparation of first component and second component, and its preparation steps are as follows:

[0055] The preparation method of the first component is:

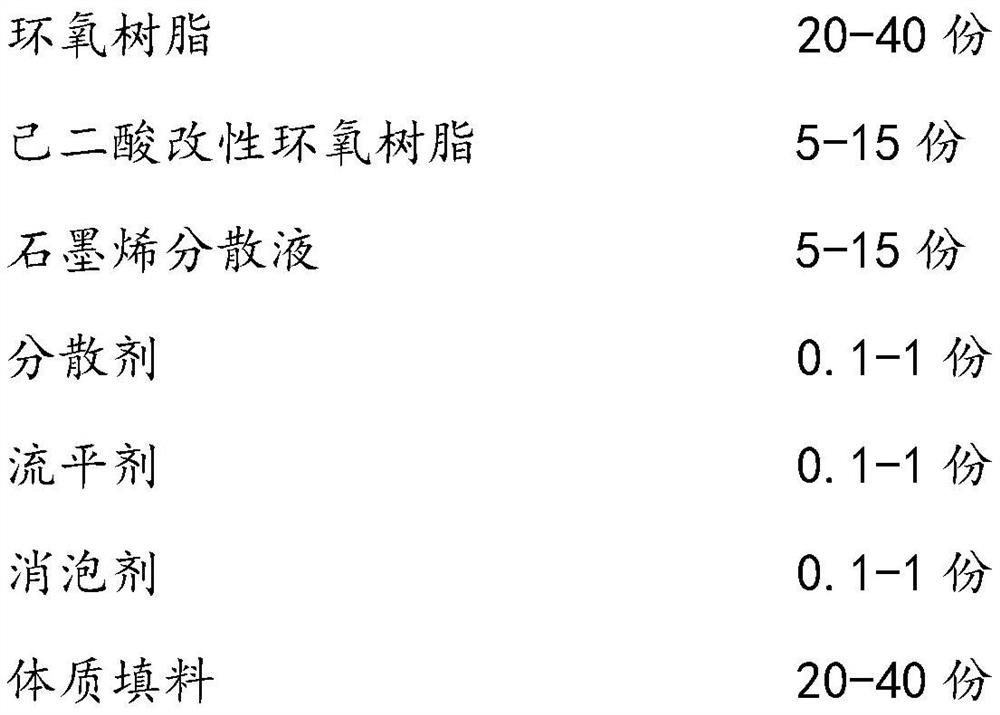

[0056] (1) Add epoxy resin, adipic acid modified epoxy resin, graphene dispersion, dispersant, defoamer, and leveling agent to the dispersion cylinder under low-speed stirring at 50-100rpm, and stir at a low speed of 1500rpm Disperse for 5-10 minutes;

[0057] (2) Add body filler and anti-rust filler, disperse at 3000rpm at high speed for 40-60min until the fineness is ≤80μm;

[0058] (3) Add a thixotropic agent to disperse at a high speed, keep the temperature at 55-65°C and continue to disperse for 25 minutes;

[0059] (4) Filtration and packaging to obtain finished products.

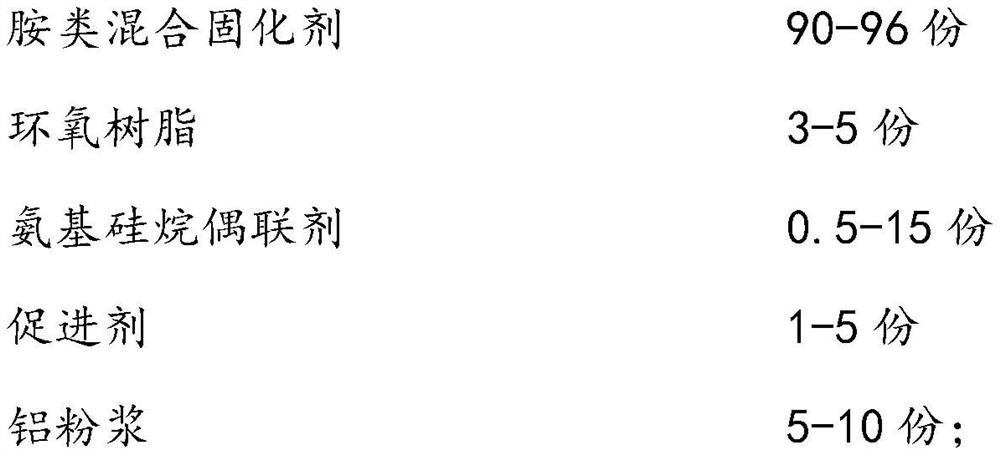

[0060] The preparation method of the second component is:

[0061] (1) Under low-speed stirr...

Embodiment 1

[0071] The epoxy resin in the first component is E51, and its epoxy equivalent is 196g / eq; The viscosity of the adipic acid modified epoxy resin is 600cp, and the epoxy value is 0.26; The dispersant is excellent Card 710S, the leveling agent is Euca 384S, the defoamer is Euca 272S, the body filler is feldspar powder, the antirust filler is nano-iron titanium powder, and the thixotropic agent is LV;

[0072] The amine value of curing agent a in the second component is 260-320 mgKOH / g, the amine value of curing agent b is 330-380 mgKOH / g, and the mass ratio of curing agent a to curing agent b is 1 : 3; the epoxy resin is E51, the aminosilane coupling agent is KH550, and the accelerator is DMP-30;

Embodiment 2

[0074] The epoxy resin in the first component is E51, and its epoxy equivalent is 196g / eq; the viscosity of the adipic acid modified epoxy resin is 650cp, and the epoxy value is 0.26; the dispersant is BYK -110, the leveling agent is BYK-320, the defoamer is Euka BYK-A530, the body filler is feldspar powder, the antirust filler is nano-iron titanium powder, and the thixotropic agent is LV;

[0075] The amine value of curing agent a in the second component is 260-320 mgKOH / g, the amine value of curing agent b is 330-380 mgKOH / g, and the mass ratio of curing agent a to curing agent b is 1 : 1; the epoxy resin is E51, the aminosilane coupling agent is KH550, and the accelerator is K54;

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com