Nanometer solvent-free epoxy anticorrosive paint and preparation method thereof

An epoxy anti-corrosion coating, solvent-free technology, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve the health impact of environmental construction personnel, no antibacterial and bactericidal effects, and limited anti-corrosion effects, etc. Problems, achieve the effect of improving anti-corrosion ability, prolonging the validity period, and low impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of corrosion inhibitor microcapsules comprises the following steps,

[0037]Step 1, at room temperature, add 0.05 to 0.2 parts of ethyl cellulose to the toluene-ethanol dispersion, so that the ethoxy content is 45% to 55%, the viscosity is 15 to 30mPa.s, and the ethyl cellulose Contains ethoxy groups, limiting the content and viscosity of ethoxy groups is to control the subsequent reaction. The toluene-ethanol dispersion can be directly mixed with toluene and ethanol, and their volume ratio does not need to be limited;

[0038] Step 2: Add 3-8g of sodium nitrite to the dispersion obtained in step 1 for reaction, then add 12-18g of polybutadiene, and stir at room temperature for 30-60 minutes;

[0039] Step 3, adding 8 to 12 g of toluene diisocyanate to the mixed system obtained in step 2 to obtain a water-insoluble mixture containing ethyl cellulose;

[0040] Step 4, putting the obtained ethylcellulose-containing mixture into an oven for drying ...

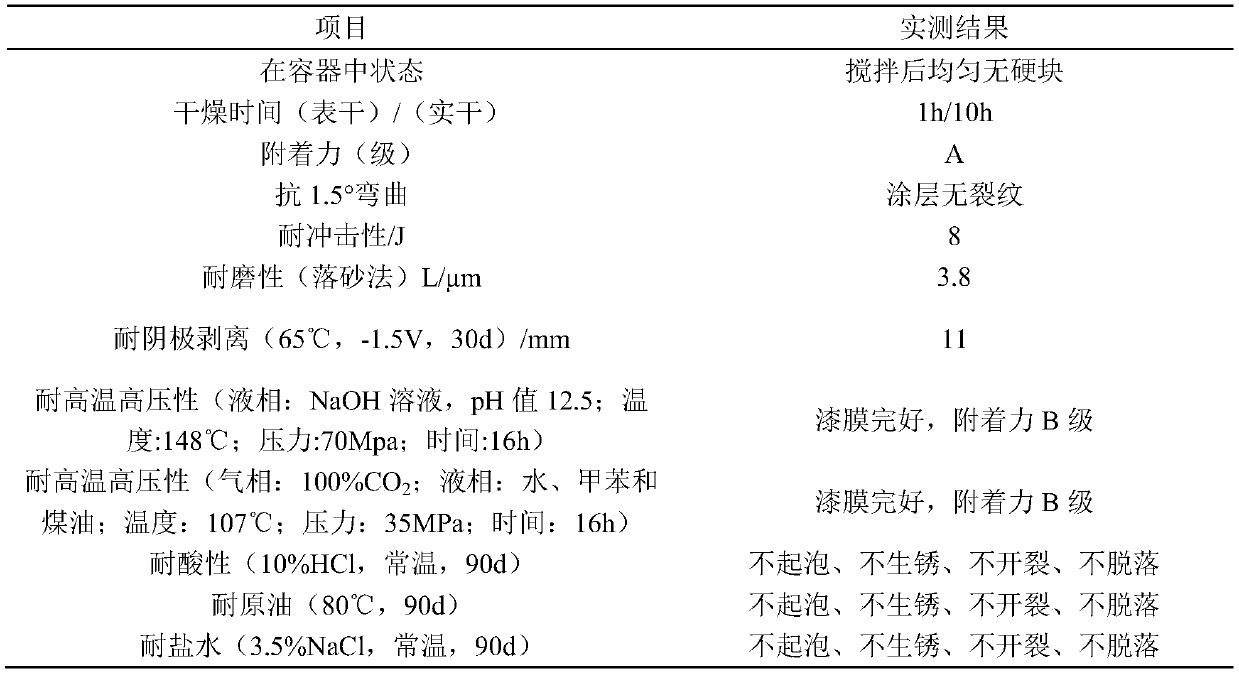

Embodiment 1

[0053] The manufacture method step of nano solvent-free epoxy anticorrosion paint of the present invention is as follows, wherein the ratio of each component is parts by weight,

[0054] Step 1, put the novolac epoxy resin into a 40°C oven for 5 hours to preheat;

[0055] Step 2, put 0.6 parts of barium sulfate, 0.2 parts of talc powder, 0.25 parts of wollastonite powder, 0.3 parts of mica powder and 0.003 parts of fumed silica in a thermostat at 150°C for 12 hours to remove water and obtain pigments and fillers;

[0056] Step 3, mix 1 part of polyether modified epoxy resin, 0.8 part of novolak epoxy resin, 0.02 part of defoamer, 0.015 part of dispersant, 0.015 part of leveling agent and stir at room temperature, stirring at 40 ° C Add 1.35 parts of pigments and fillers, 0.05 parts of nano-TiO 2 , continue to stir at a speed of 1000rpm for 35min to disperse the components evenly, then use a grinder to grind for 0.8 hours, and finally add 0.005 parts of corrosion inhibitor ca...

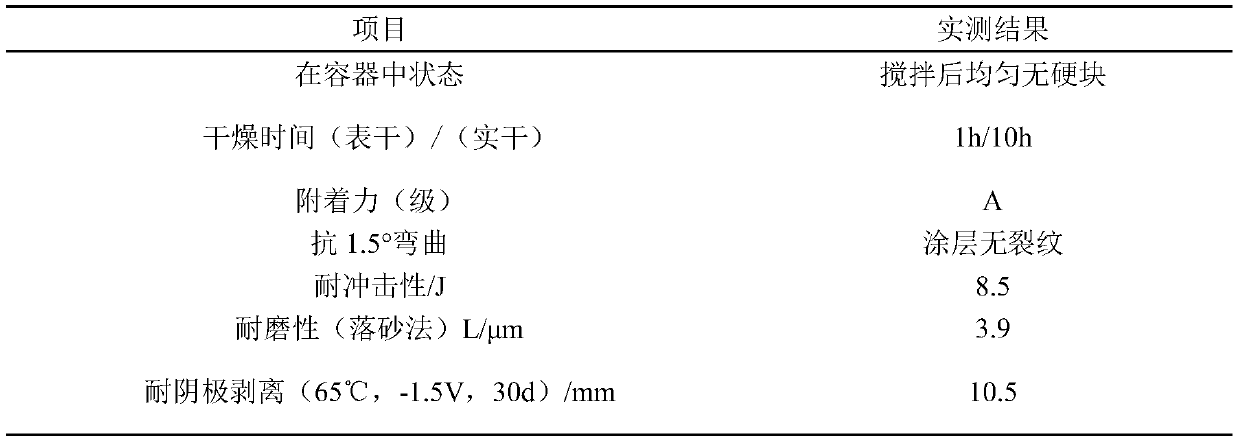

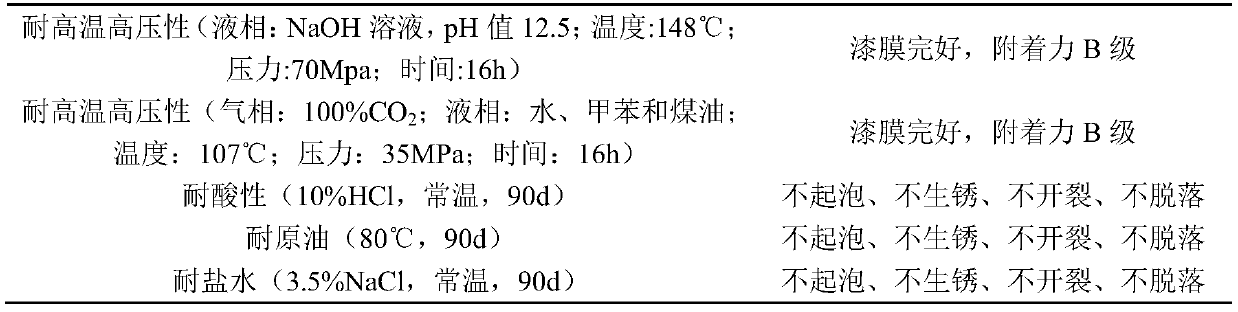

Embodiment 2

[0071] The manufacture method step of nano solvent-free epoxy anticorrosion paint of the present invention is as follows, wherein the ratio of each component is parts by weight,

[0072] Step 1, put the novolac epoxy resin into a 40°C oven for 5 hours to preheat;

[0073] Step 2, put 0.7 parts of barium sulfate, 0.3 parts of talc powder, 0.25 parts of wollastonite powder, 0.4 parts of mica powder and 0.004 parts of fumed silica in a thermostat at 150°C for 12 hours to remove water and obtain pigments and fillers;

[0074] Step 3, mix 1 part of polyether modified epoxy resin, 0.9 part of novolak epoxy resin, 0.0254 part of defoamer, 0.0178 part of dispersant, 0.018 part of leveling agent and stir at room temperature, stirring at 45 ° C Add 1.8 parts of pigments and fillers, 0.075 parts of nano-TiO 2 , continue to stir at a speed of 2000rpm for 35min to disperse the components evenly, then grind for 1 hour with a grinder, and finally add 0.005 parts of corrosion inhibitor caps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com