Preparation method of photo-curable graphene solvent-free epoxy fiberglass reinforced plastic paint

An epoxy fiberglass and graphene-based technology, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of poor wear resistance, oxygen polymerization inhibition, complex preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

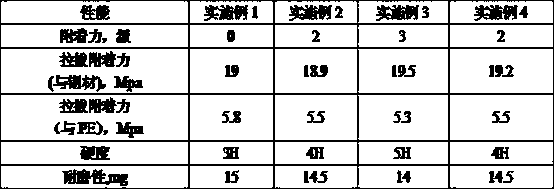

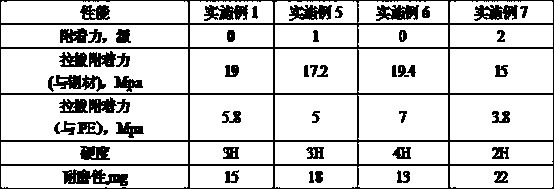

Examples

Embodiment 1

[0010] A kind of photocuring graphene type solvent-free epoxy FRP coating described in the present embodiment and its preparation method are made of the following raw materials in weight percentage:

[0011] Epoxy resin E51 24%

[0012] Epoxy acrylate resin 6104 6%

[0013] Monofunctional monomer IBOA 15%

[0014] Difunctional monomer HDDA 7.5%

[0015] Multifunctional monomer (≥3) TMPTA 7.5%

[0016] Glass fiber powder 36%

[0017] Free radical photoinitiator 184 1%

[0018] Cationic photoinitiator I-160 1%

[0019] Adhesion Promoter 1%

[0020] Defoamer 0.5%

[0022] Preparation method: Feed the monomer according to the above ratio, stir evenly, slowly add photoinitiator, stir until completely dissolved, add epoxy resin and epoxy acrylate resin in sequence according to the above formula ratio, stir and mix evenly, put into glass Fiber powder, dispersed at high speed, stirred evenly, and then put into adhesion promoter, defoamer, graphene o...

Embodiment 2

[0025] Epoxy resin E51 24%

[0026] Epoxy acrylate resin 6104 6%

[0027] Monofunctional monomer IBOA 7.5%

[0028] Difunctional monomer HDDA 15%

[0029] Multifunctional monomer (≥3) TMPTA 7.5%

[0030] Glass fiber powder 36%

[0031] Free radical photoinitiator 184 1%

[0032] Cationic photoinitiator I-160 1%

[0033] Adhesion Promoter 1%

[0034] Defoamer 0.5%

[0036] Preparation process and method of use are the same as in Example 1

Embodiment 3

[0038] Epoxy resin E51 24%

[0039] Epoxy acrylate resin 6104 6%

[0040] Monofunctional monomer IBOA 7.5%

[0041] Difunctional monomer HDDA 7.5%

[0042] Multifunctional monomer (≥3) TMPTA 15%

[0043] Glass fiber powder 36%

[0044] Free radical photoinitiator 184 1%

[0045] Cationic photoinitiator I-160 1%

[0046] Adhesion Promoter 1%

[0047] Defoamer 0.5%

[0049] Preparation process and method of use are the same as in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com