Ultrahigh-concentration-multiple circulating cooling water treatment system and circulating cooling water treatment method

A technology of circulating cooling water and concentration multiples, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion exchange water/sewage treatment, etc. Water supply and other issues, to reduce project investment costs and operating costs, to solve the effect of rising thermal resistance of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

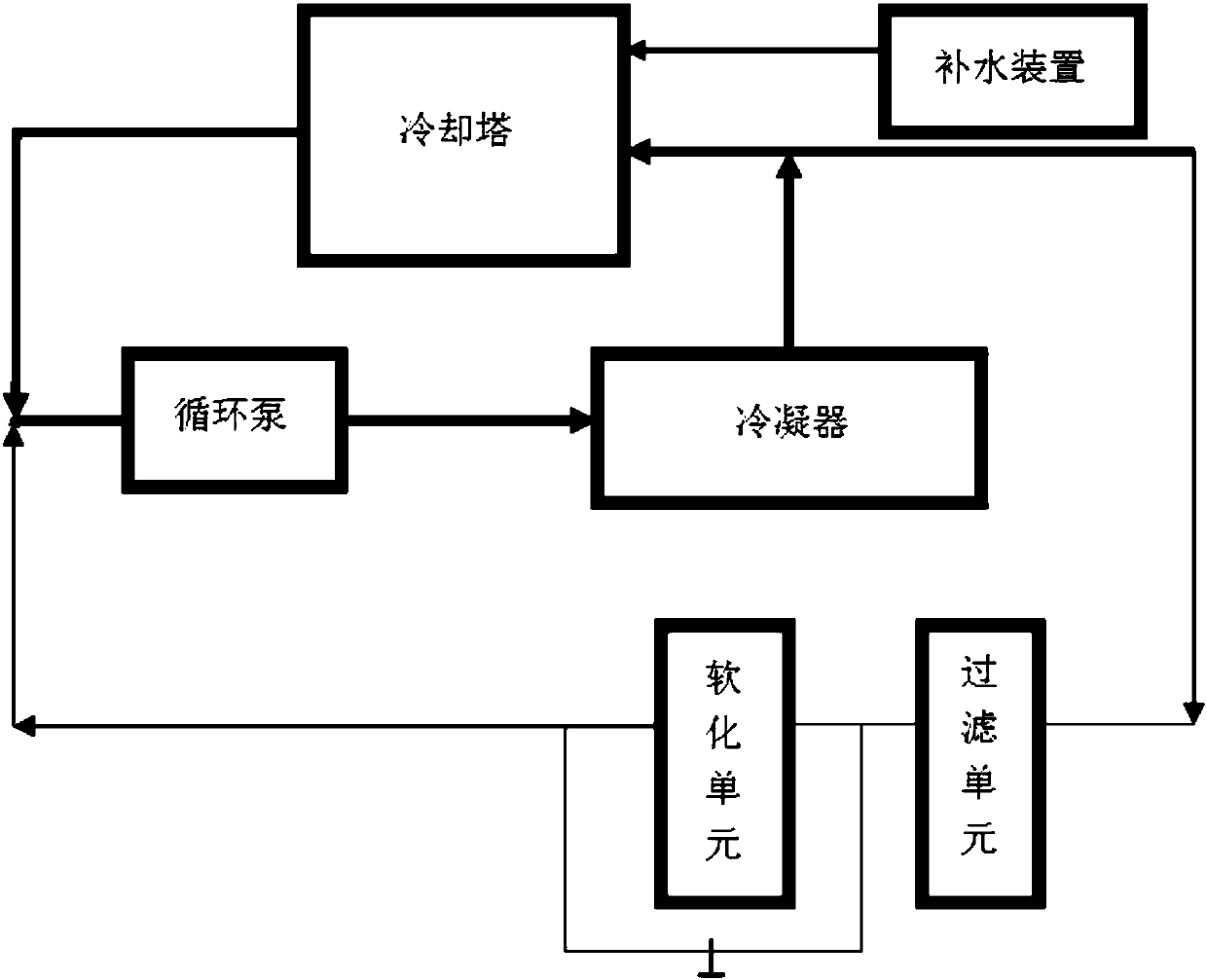

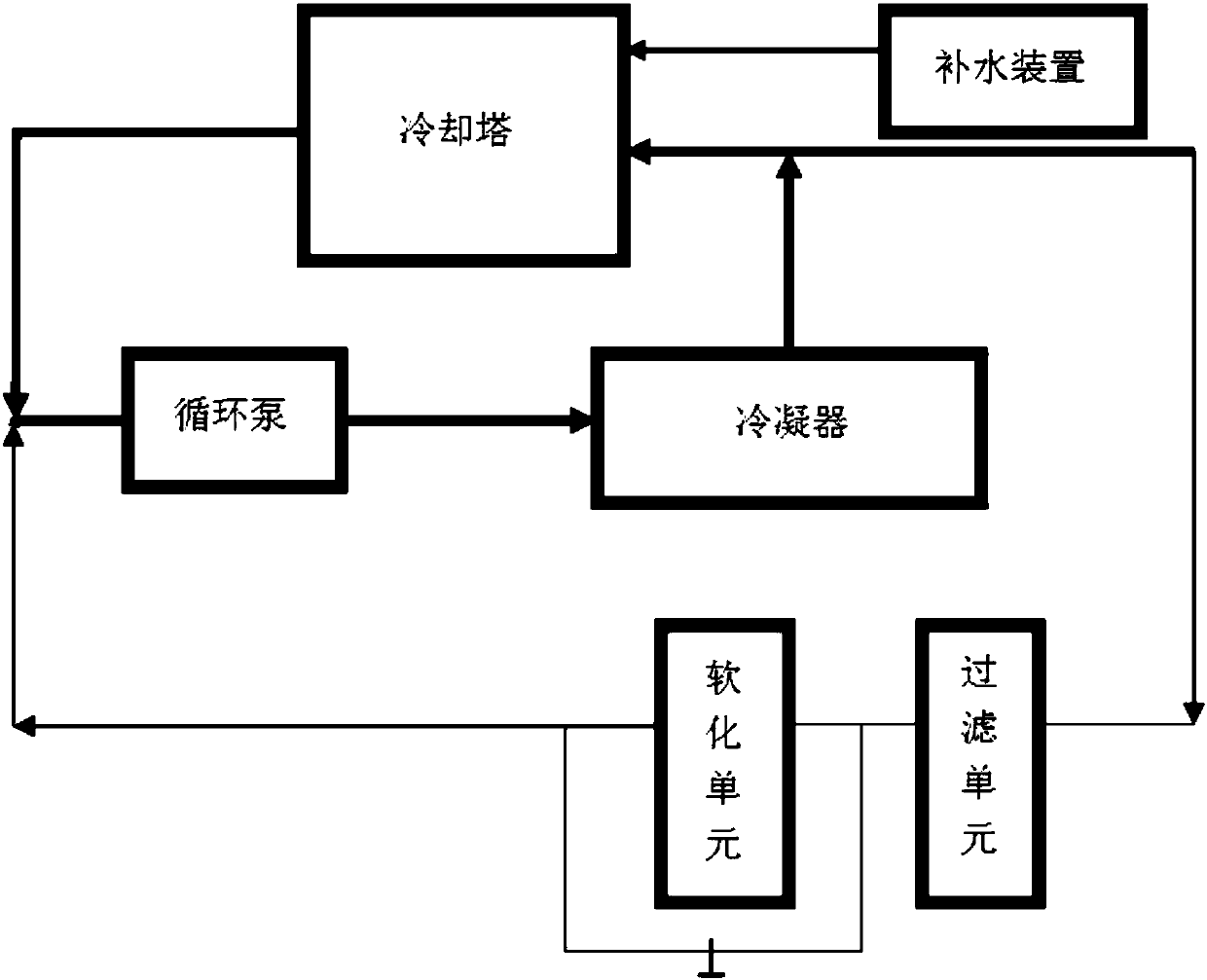

[0033] Refer to attached figure 1 As shown, the circulating cooling water treatment system of the present invention includes a circulating cooling water system and a bypass treatment system cyclically connected with the circulating cooling water system.

[0034] The circulating cooling water system belongs to an open cooling circulating water system, and a circulating pump, a condenser and a cooling tower are arranged on the circulating pipeline. The cooling tower is also connected with a water supply device. The water inlet of the bypass treatment system is arranged on the pipeline between the condenser and the cooling tower, and the water outlet of the bypass treatment system is arranged on the pipeline between the cooling tower and the circulating pump.

[0035] The bypass treatment system in the present invention includes a filter unit and a softening unit connected in sequence. Among them, the filter unit adopts one or more of disc filter, multi-media filter or suction ...

Embodiment 2

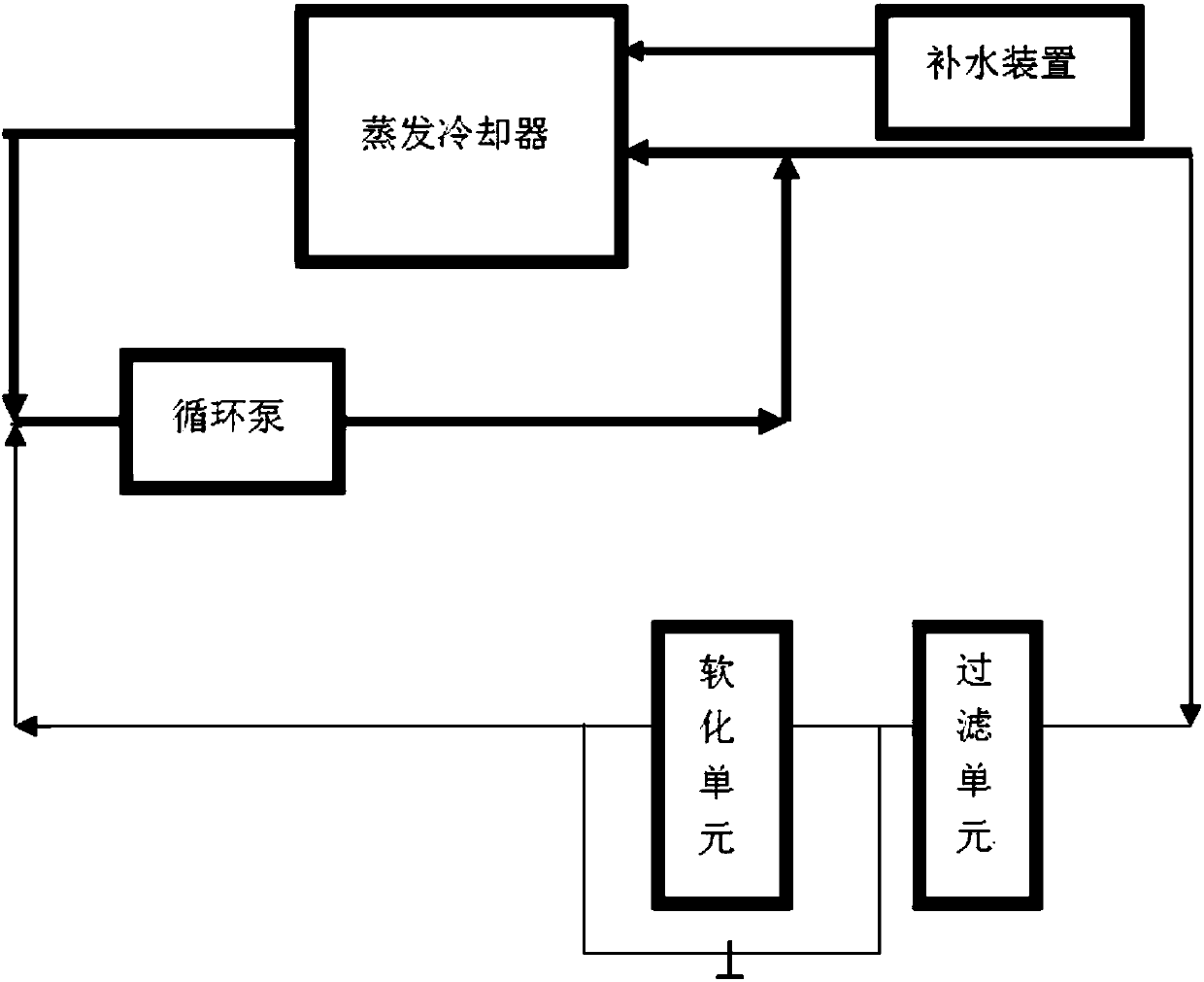

[0039] The difference between the second embodiment and the first embodiment is that the circulating cooling water system belongs to the evaporative cooling circulating water system. figure 2 As shown, the circulation pipeline is equipped with a circulation pump and an evaporative cooler. The water inlet and the water outlet of the bypass treatment system are respectively arranged on the water outlet pipe and the water inlet pipe of the circulation pump. And the evaporative cooler is also connected with a water supply device. Other parts are the same as those in Embodiment 1, and will not be repeated here.

[0040] A more preferred embodiment is: a bypass passage is provided at the water inlet and outlet of the softening unit in the first and second embodiments above, and a valve is provided on the bypass passage. In this way, according to the actual water quality of the circulating cooling water, it can be selected whether it needs to be softened, flexible control and cost...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com