Polysulfide sealant microcapsule as well as preparation method and application thereof

A polysulfide sealant and microcapsule technology, which is applied in the field of sealing and anti-corrosion technology, can solve the problems of difficulty in ensuring the quality of gluing and assembly, low assembly efficiency, affecting sealing and corrosion protection, etc. The effect of assembly quality, improving labor efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the polysulfide sealant microcapsules in the present invention is a solution in-situ polymerization method. First, the sealant is diluted with a diluent, and then the polysulfide sealant is emulsified and dispersed in the water phase under rapid stirring conditions to form an O / W Add a mixed solution of urea and formaldehyde to the emulsion, adjust the pH value to acidic with dilute acid, and then polymerize at 20-50°C for 6-24 hours under stirring. Capsule; in parts by weight, the reaction monomer comprises the following components:

[0030]

[0031]

Embodiment 1

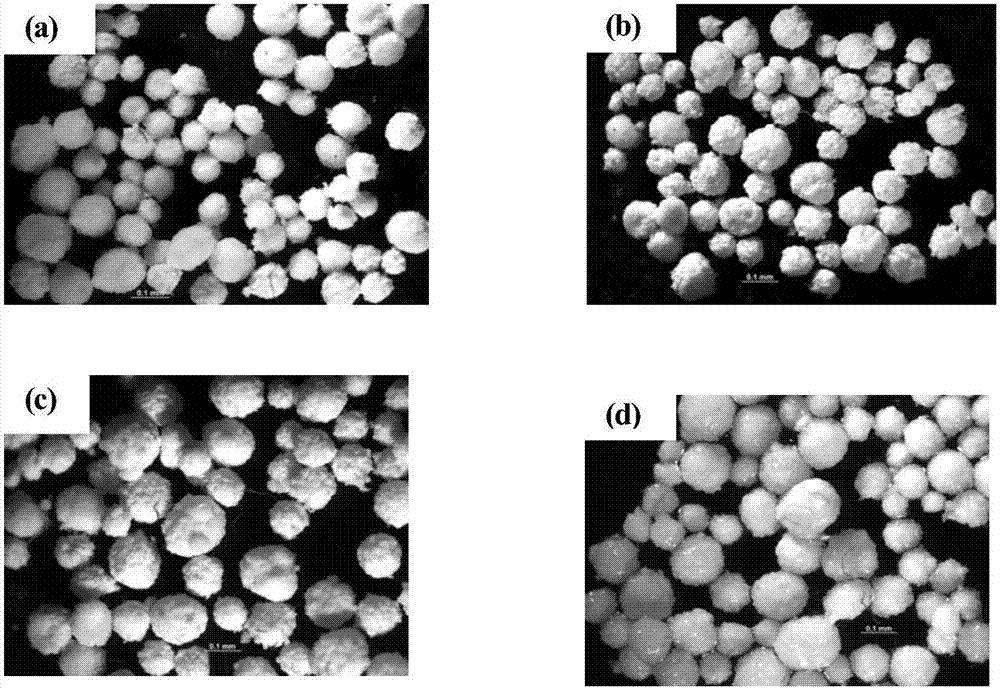

[0034] First weigh 4g of polysulfide sealant and dilute it with 3ml of acetone, then mix the sealant with 80ml of 1% sodium dodecylbenzenesulfonate solution under stirring at 1000rpm, emulsify and disperse for 1h to form an O / W emulsion . Weigh 1.5g of urea and 3.5g of 37wt.% formaldehyde aqueous solution, add them to the emulsified sealant solution respectively, and continue to stir for 0.5h. After the urea is completely dissolved, adjust the pH value of the solution to about 4 with dilute hydrochloric acid. and 300 rpm under the condition of stirring for 8 hours, the reaction product was washed with distilled water successively, vacuum filtered, and the filter cake was dried at room temperature to obtain microcapsules coated with polysulfide rubber. The surface morphology of the prepared sealant microcapsules is as follows: figure 1 (a).

Embodiment 2

[0036] Weigh 5g of polysulfide sealant, stir and dilute it with 10ml of ethyl acetate, add the sealant dropwise to 80ml of 1% sodium dodecylbenzenesulfonate solution under stirring condition of 800rpm, emulsify and disperse for 1h to form O / W emulsion. Weigh 2.0g and 6.0g of urea in 37wt.,% formaldehyde solution, respectively add them to the emulsified polysulfide sealant solution, and then continue to stir for 0.5h. After the urea is completely dissolved, adjust the pH value of the solution with 0.2M citric acid to Around 4, the temperature of the water bath was raised to 40°C, and the polymerization reaction was carried out at 500 rpm for 12 hours. The product was washed with ethanol, vacuum filtered, and dried under vacuum at room temperature to obtain microcapsules coated with polysulfide rubber. The surface morphology of the prepared sealant microcapsules is as follows: figure 1 (b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com