Self-repair coating with anticorrosion and antifouling double functions and method for preparing self-repair coating

A self-healing, dual-function technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., to achieve the effects of excellent film formation, high yield and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

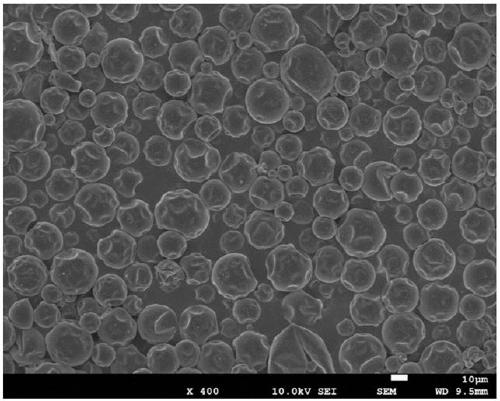

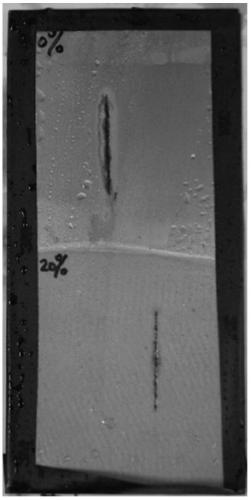

Embodiment 1

[0055] At room temperature, add 120mL of distilled water to a 500mL flask, add 13.5g of gum arabic emulsifier, stir mechanically at 500rpm for 4 hours until the upper layer of foam and the lower layer are clear, then add 2.5g of urea, 0.25g of ammonium chloride, and 0.25g of resorcinol , adjust the pH of the mixture to 3.5; at the same time, dissolve 2.7g DCOIT in 27g isophorone diisocyanate, and disperse evenly by ultrasonication. Then, add 4g Bayer Desmodur L75 to a 500mL two-necked flask, and mix with 4mL ethyl acetate under nitrogen atmosphere Stir evenly for 10 minutes, then add 27g of isophorone diisocyanate and stir until the two are evenly mixed, then slowly pour the premixed emulsifier mixture into the flask, emulsify at 1100rpm for 10min, add 6.33g of formaldehyde with a mass fraction of 37% Aqueous solution, heated to 55°C, reacted for 3 hours, cooled to room temperature after the reaction, decanted and separated, repeated three times with distilled water, dried at r...

Embodiment 2

[0065] At room temperature, add 120mL of distilled water to a 500mL flask, add 15g of polyvinyl alcohol, stir mechanically at 90°C for 4 hours until it becomes transparent, then add 2.5g of urea, 0.25g of ammonium chloride, and 0.25g of resorcinol in sequence to adjust the mixture pH to 3.5; at the same time, dissolve 10g DCOIT in 20g isophorone diisocyanate, ultrasonically disperse evenly, then add 4g hexamethylene diisocyanate prepolymer in a 500mL two-necked flask, and mix with 4mL acetone under nitrogen atmosphere Stir, then add the above-mentioned mixture of isophorone diisocyanate and DCOIT and stir until uniformly mixed, then slowly pour the premixed emulsifier into the flask, emulsify at 1100rpm for 10min, add 6.5g of formaldehyde solution with a mass fraction of 37% , heated to 55°C, reacted for 3 hours, cooled to room temperature after the reaction, decanted and separated, repeated three times with distilled water, dried at room temperature, then sieved, sealed and st...

Embodiment 3

[0069] At room temperature, add 120mL of distilled water to a 500mL flask, add 20g of sodium dodecylbenzenesulfonate, stir until completely dissolved, then add 2.5g of urea, 0.25g of ammonium chloride, and 0.25g of resorcinol in sequence to adjust the mixture pH to 3.5; at the same time, dissolve 10g of chlorothalonil in 20g of 4,4'-dicyclohexylmethane diisocyanate, and disperse evenly by ultrasonic, then slowly add the emulsifier solution to the mixture of isocyanate and DCOIT, and stir until uniformly mixed , emulsified at 900rpm for 10min, added 10g of formaldehyde solution with a mass fraction of 37%, ultrasonicated in an ice bath for 15min, heated to 55°C, and reacted for 4 hours. After the reaction, cooled to room temperature, poured and separated, repeated three times with distilled water, and dried at room temperature Then sieve and store in a vacuum desiccator.

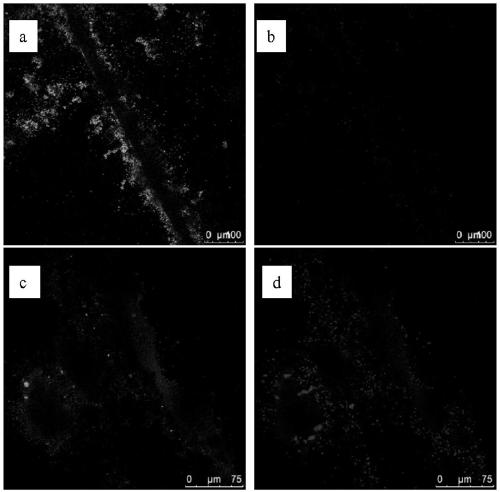

[0070] Disperse the microcapsules in a certain amount of distilled water, add a certain amount of DISPERBY...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com