Composition for forming magnesium-lithium alloy surface anticorrosive coating system and preparation method of anticorrosive coating system

A technology of magnesium-lithium alloy and anti-corrosion coating, which is applied to the device for coating liquid on the surface, anti-corrosion coating, coating, etc., to achieve excellent anti-corrosion performance, improve environmental adaptability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

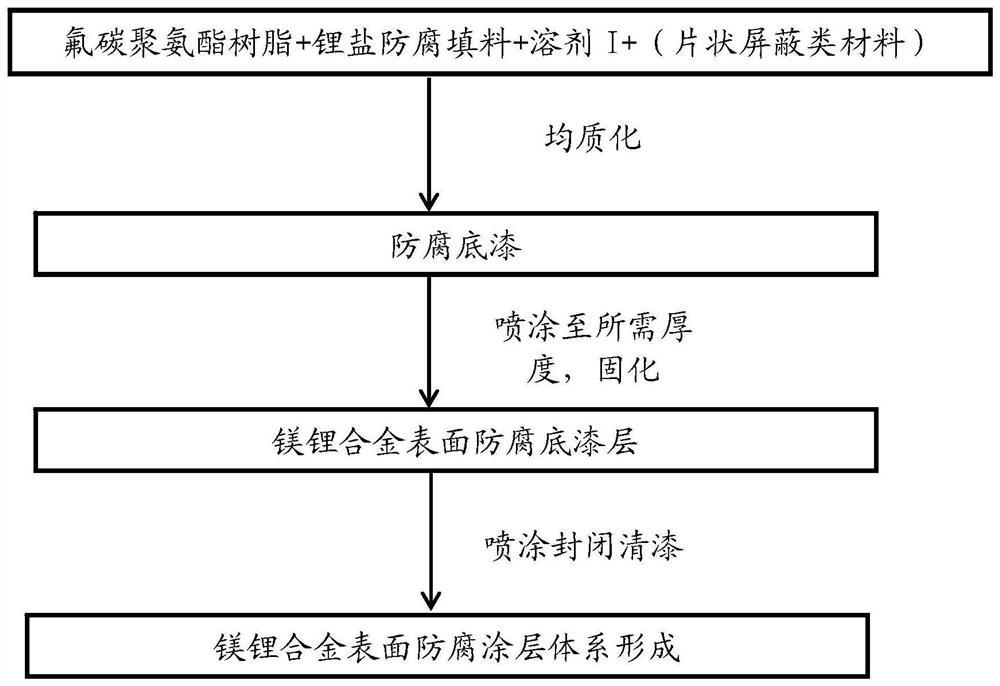

[0046] According to a second aspect of the present invention, a method for preparing a magnesium-lithium alloy surface anti-corrosion coating system is provided, which is formed by using the above-mentioned composition for forming a magnesium-lithium alloy surface anti-corrosion coating system, such as figure 1 shown, including the following steps:

[0047] Step 1, after stirring and mixing the components in the anti-corrosion primer, perform homogenization, homogenize for 2-7 hours to form an anti-corrosion primer; homogenization means include but not limited to ball milling, sand milling, high-speed dispersion, etc.;

[0048] Step 2, spraying an anti-corrosion primer on the surface of the magnesium-lithium alloy after micro-arc oxidation, curing to form an anti-corrosion primer layer;

[0049] Step 3, spraying a sealing varnish on the surface of the cured anticorrosion primer layer, and curing to form a sealing varnish layer.

[0050] In a preferred embodiment, if a solvent...

Embodiment 1

[0057] Magnesium-lithium alloy surface anti-corrosion primer, its raw material ratio is: Lithium nitrate 5g, GK570 fluorocarbon polyurethane 80g, sericite 2g, butyl acetate 22g, after stirring and mixing evenly, use ball mill to grind and mix for 4 hours to form anti-corrosion primer.

[0058] The anti-corrosion primer was prepared by continuous spraying on the surface of the magnesium-lithium alloy substrate after micro-arc oxidation by air spraying process, and the thickness of the anti-corrosion primer layer was 60 μm.

[0059] After the anti-corrosion primer is dried and cured, use the air spraying process to continuously spray GK570 fluorocarbon polyurethane varnish on the surface of the anti-corrosion primer to seal the surface. The thickness of the sealed varnish layer is 20 μm. GK570 fluorocarbon polyurethane varnish contains 20wt% butyl acetate.

[0060] After the magnesium-lithium alloy surface anti-corrosion coating system was continuously sprayed with salt spray fo...

Embodiment 2

[0063] Magnesium-lithium alloy surface anti-corrosion primer, its raw material ratio is: Lithium chloride 5g, E44 epoxy resin 95g, sericite 15g, ethyl acetate 115g, after stirring and mixing evenly, use ball mill to grind and mix 7h to form anti-corrosion primer.

[0064] The anti-corrosion primer was prepared by continuous spraying on the surface of the magnesium-lithium alloy substrate after micro-arc oxidation by air spraying process, and the thickness of the anti-corrosion primer layer was 20 μm.

[0065] After the anti-corrosion primer is dried and cured, use the air spraying process to continuously spray E51 epoxy resin varnish on the surface of the anti-corrosion primer to seal the surface. The thickness of the sealed varnish layer is 20 μm. E51 epoxy resin varnish contains 80wt%.

[0066] After the magnesium-lithium alloy surface anti-corrosion coating system was continuously sprayed with salt spray for 1000 hours, the surface of the paint film of the three samples cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com