A kind of preparation method of cupronickel b30 with superhydrophobic surface of corrosion inhibition performance

A super-hydrophobic surface, cupronickel technology, applied in the field of electrochemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of preparation method of the cupronickel B30 with the superhydrophobic surface of anticorrosion property, comprises the steps:

[0041] (1) Preparation of etching solution

[0042] At a concentration of 20% (w) FeCl 3 Adding hydrochloric acid with a concentration of 35-37% (w) into the aqueous solution to make the concentration of hydrochloric acid in the etching solution 0.33% (v);

[0043] (2), pretreatment of cupronickel

[0044] Divide 6 specifications into (1×1)cm 2 Cupronickel B30 electrodes and 6 pieces (70×10×2)cm 2 The white copper B30 sheet is polished by 1#, 3#, 6# metallographic sandpaper in turn, cleaned with an ultrasonic cleaner in acetone solution for about 5 minutes, and then rinsed with ethanol and deionized water in order to remove surface oil and dirt. grease;

[0045] (3) Etching on the surface of cupronickel

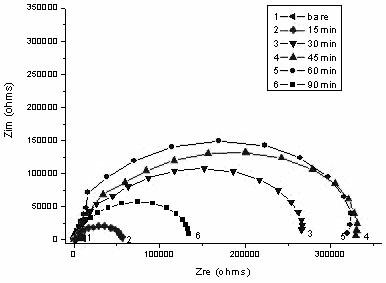

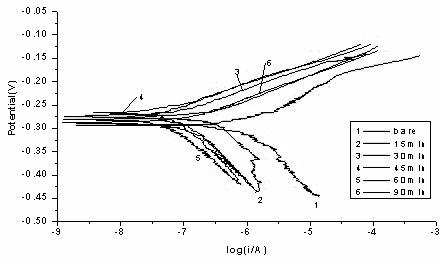

[0046] Put 5 cupronickel B30 electrodes and 5 cupronickel B30 sheets pretreated in step (2) into the etching solution obtained ...

Embodiment 2

[0058] A preparation method of cupronickel B30 with super-hydrophobic surface with corrosion inhibition performance, comprising the following steps:

[0059] (1) Preparation of etching solution

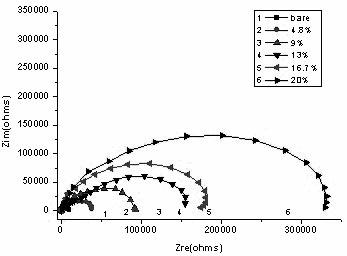

[0060] Concentrations of 4.8%(w), 9%(w), 13%(w), 16.7%(w) and 20%(w) FeCl 3 Add hydrochloric acid with a concentration of 35-37% (w) to the aqueous solution, so that the concentration of hydrochloric acid in the etching solution is 0.33% (v);

[0061] (2) Pretreatment of cupronickel B30

[0062] The 6 sizes are (1×1)cm 2 Cupronickel 30 electrodes and 6 pieces (70×10×2) cm 2 The white copper B30 pieces are polished with 1#, 3#, and 6# metallographic sandpaper in turn, then cleaned with an ultrasonic cleaner in acetone solution for about 5 minutes, and then rinsed with ethanol and deionized water in turn to remove surface oil and dirt. grease;

[0063] (3) Etching on the surface of cupronickel B30

[0064] Put 5 cupronickel B30 electrodes and 5 cupronickel B30 sheets pretreated in...

Embodiment 3

[0077] A preparation method of cupronickel B30 with super-hydrophobic surface with corrosion inhibition performance, comprising the following steps:

[0078] (1) Preparation of etching solution

[0079] FeCl at a concentration of 9 %(w) 3 Add hydrochloric acid with a concentration of 35-37% (w) to the aqueous solution, so that the concentration of hydrochloric acid in the etching solution is 0.33% (v);

[0080] (2) Pretreatment of cupronickel B30

[0081] The 6 sizes are (1×1)cm 2 cupronickel B30 electrodes and 6 pieces (70×10×2)cm 2 The white copper B30 pieces are ground by 1#, 3#, and 6# metallographic sandpaper in turn, then cleaned with an ultrasonic cleaner in acetone solution for about 5 minutes, and then rinsed with ethanol and deionized water in turn to remove surface oil and dirt. grease;

[0082] (3) Etching on the surface of cupronickel B30

[0083] Put 5 cupronickel B30 electrodes and 5 cupronickel B30 sheets pretreated in step (2) into the etching solution o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com