Method for preparing aluminium alloy/trivalent chromium composite conversion film and film-forming liquid thereof

A technology of aluminum alloy and film-forming liquid, applied in the direction of metal material coating process, etc., can solve the problems of different substrate properties, single conversion coating composition, trivalent chromium conversion coating cannot be used for aluminum alloy treatment, etc., and achieves low cost. , Improve the anti-corrosion performance and facilitate the effect of production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

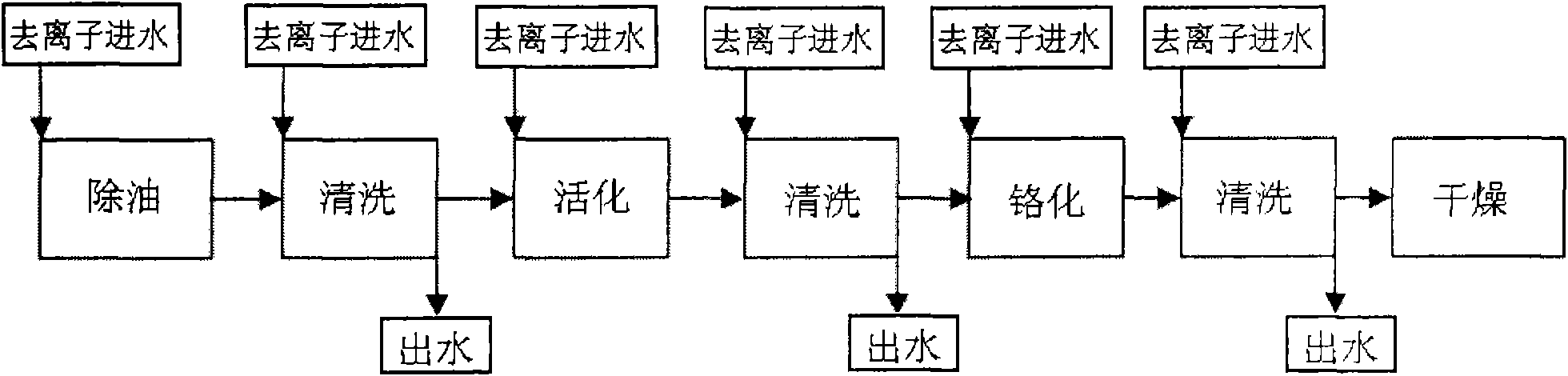

Image

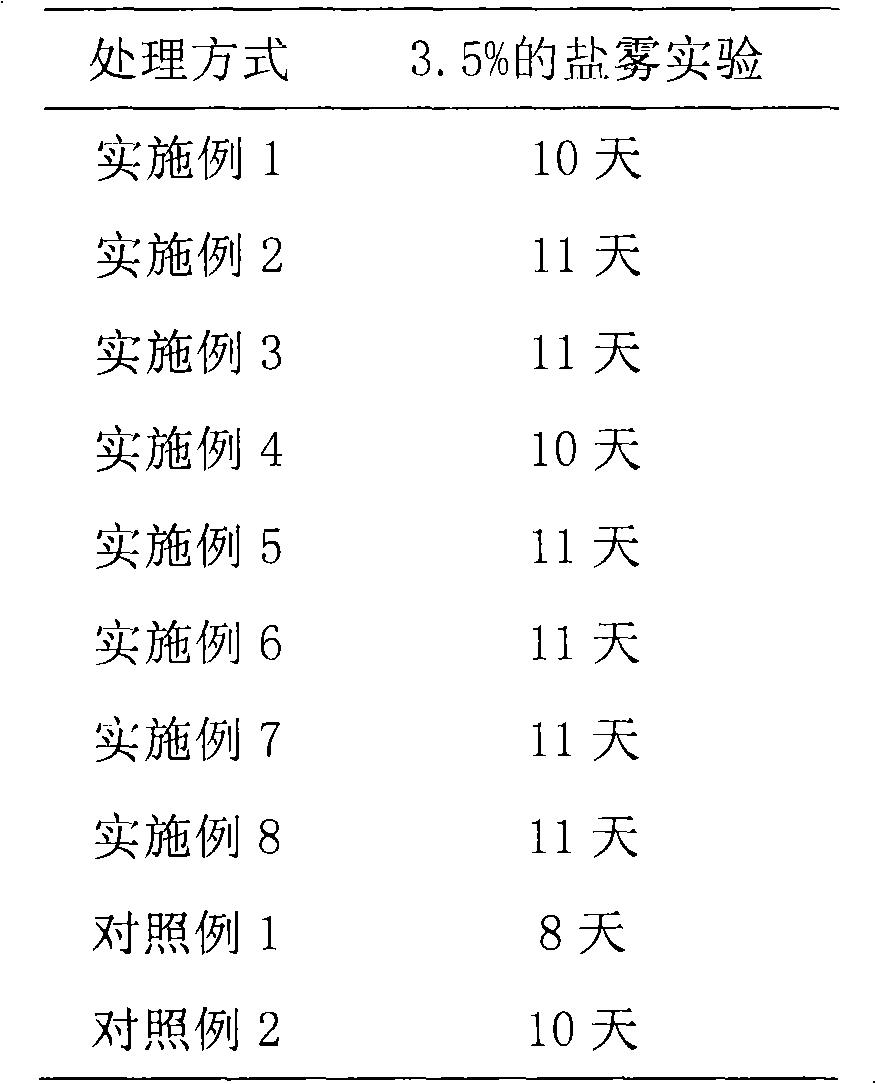

Examples

Embodiment 77075

[0067] Embodiment 77075 aluminum alloy trivalent chromium chromization

[0068] A. Build a 500L degreasing bath: Clean the container thoroughly before building the bath. For new containers or new production lines, first wash with 50L of 10% sulfuric acid solution, then wash with water twice, each time with 100L of water, and then add Henkel's degreasing agent 12KgRidoline212, then diluted to 500L with deionized water, the pH is controlled within the range of 7-8, and mixed evenly.

[0069] B. Building an activation bath: Clean the container thoroughly before building the bath. For a new container or a new production line, first clean it with 15% sulfuric acid solution, then clean it with water, add the required 12Kg of sodium hydroxide, and then Dissolve with deionized water and then dilute to 500L with deionized water, mix well, and keep the temperature at 17°C.

[0070] C. Build a 500L chromium bath: Clean the container thoroughly before building the bath. For new container...

Embodiment 8

[0075] Example 8 Trivalent Chromium Chromization of Aluminum Alloy Die Castings

[0076] A. Build a 300L degreasing bath: Clean the container thoroughly before building the bath. For new containers or new production lines, first wash with 50L of 20% sulfuric acid solution, then wash with water twice, each time with 60L of water, and then add Henkel's degreasing powder Ridoline 2128Kg is released to 300L, then diluted to 300L with deionized water, the pH is controlled within the range of 7-8, and mixed evenly.

[0077] B. Building an activation bath: Clean the container thoroughly before building the bath. For a new container or a new production line, first clean it with 15% sulfuric acid solution, then clean it with water, add the required 8Kg of sodium hydroxide, and then Dissolve with deionized water and then dilute to 300L with deionized water, mix well, and keep the temperature at 26°C.

[0078] C. Build a 300L chromium bath: clean the container thoroughly before building...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com