Process method of coating line

A process method and coating line technology, applied in the direction of surface coating liquid device, coating, electrolytic coating, etc., can solve the problem that the surface of the car cannot achieve anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

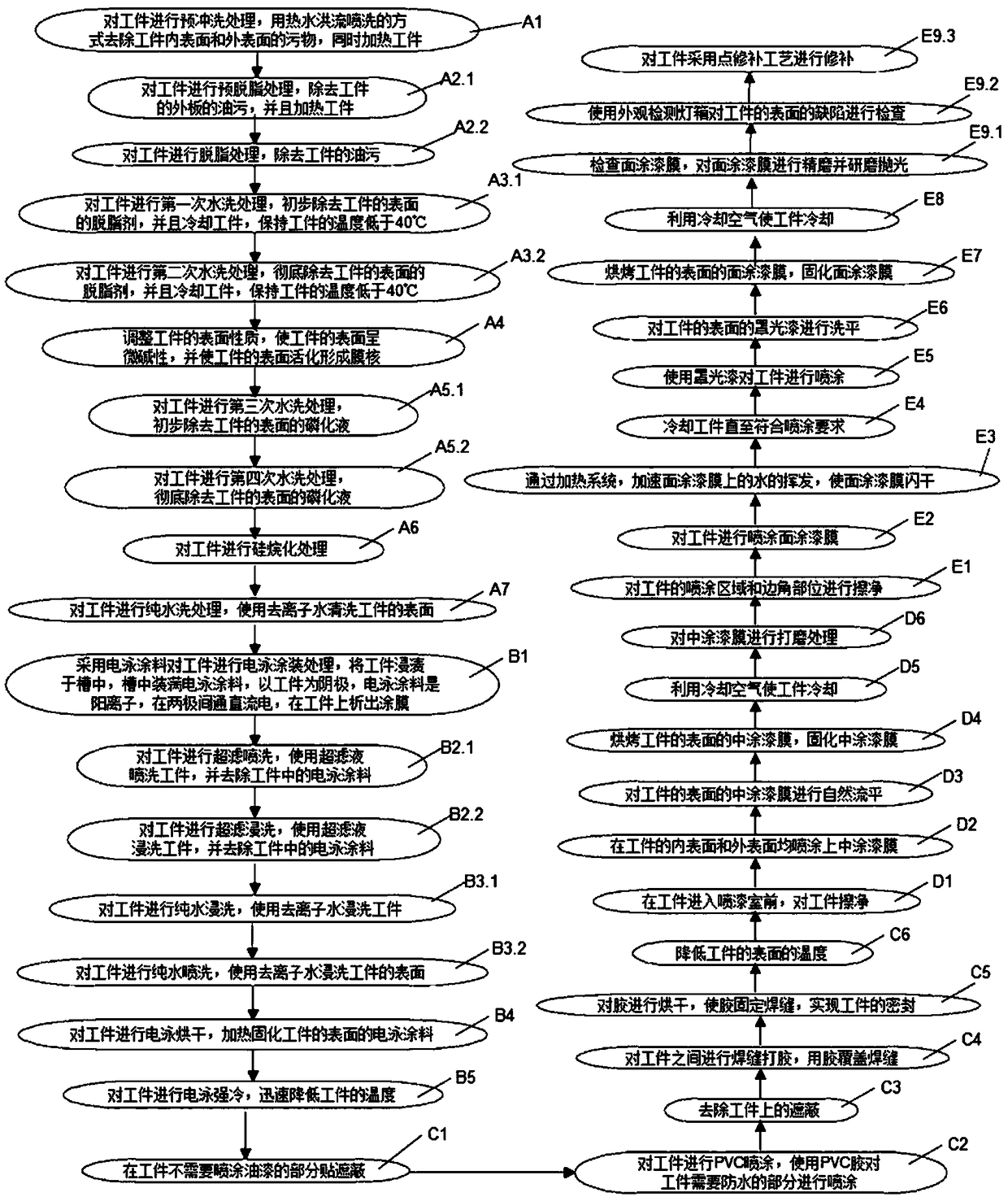

[0109] In further embodiments of the present invention, please continue to refer to figure 1 As shown, in step A2, also include:

[0110] Step A2.1: pre-degreasing the workpiece, removing oil from the outer plate of the workpiece, and heating the workpiece;

[0111] Step A2.2: Degrease the workpiece to remove oil from the workpiece.

[0112] In a further embodiment of the present invention, in step A3, also includes:

[0113] Step A3.1: Carry out the first water washing treatment to the workpiece, preliminarily remove the degreasing agent on the surface of the workpiece, and cool the workpiece to keep the temperature of the workpiece below 40°C; preferably, the first water washing treatment removes the degreasing agent on the surface of the workpiece Most skim fluids.

[0114] Step A3.2: Carry out a second water washing treatment on the workpiece to completely remove the degreasing agent on the surface of the workpiece, and cool the workpiece to keep the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com