Recrystallization method for preparing small-particle nitrate

A nitrate and recrystallization technology, applied in the preparation and molding of calcium/strontium/barium nitrate, alkali metal nitrate, lithium nitrate, etc., can solve the problems of low charge density, burning or explosion, and affecting charge density. Achieve the effect of uniform particle size, mild reaction conditions and smooth particle surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present embodiment provides a recrystallization method for preparing small particle nitrate, comprising the following steps:

[0025] 1) Dissolve 15g of cesium nitrate raw material in 50mL of deionized water, and filter the solution into a 100mL beaker for later use;

[0026] 2) Add 100mL of absolute ethanol to the 250mL flask, fix the flask on an electric stirring device with a water bath, set the constant temperature water bath to 30°C, turn on stirring, rotate at 300rpm, and after 2min,

[0027] 3) Turn on the constant flow pump and dropwise add the filtrate in the 100mL beaker to the flask, and the drop rate is 20mL / min; after all the dropwise additions are completed, continue stirring for 2h for crystallization;

[0028] 4) Filter, wash, dry and weigh the mixture in the crystallization kettle.

[0029] The weight of cesium nitrate crystal is about 13.4 g, and the yield of cesium nitrate is 89.3%.

Embodiment 2

[0031] The present embodiment provides a recrystallization method for preparing small particle nitrate, comprising the following steps:

[0032] 1) Dissolve 40g potassium nitrate raw material in 100mL deionized water, and filter the solution into a 250mL beaker for later use;

[0033] 2) Add 400mL absolute ethanol to the 1000mL flask, fix the flask on an electric stirring device with a water bath, set the constant temperature water bath to 35°C, turn on stirring, rotate at 400rpm, after 5min;

[0034] 3) Turn on the constant flow pump and dropwise add the filtrate in the 250mL beaker to the flask, and the drop rate is 30mL / min; after all the dropwise additions are completed, continue stirring for 3h for crystallization;

[0035] 4) Filter, wash, dry and weigh the mixture in the crystallization kettle.

[0036] The potassium nitrate crystal weight was about 35.8 g, and the potassium nitrate yield was 89.5%.

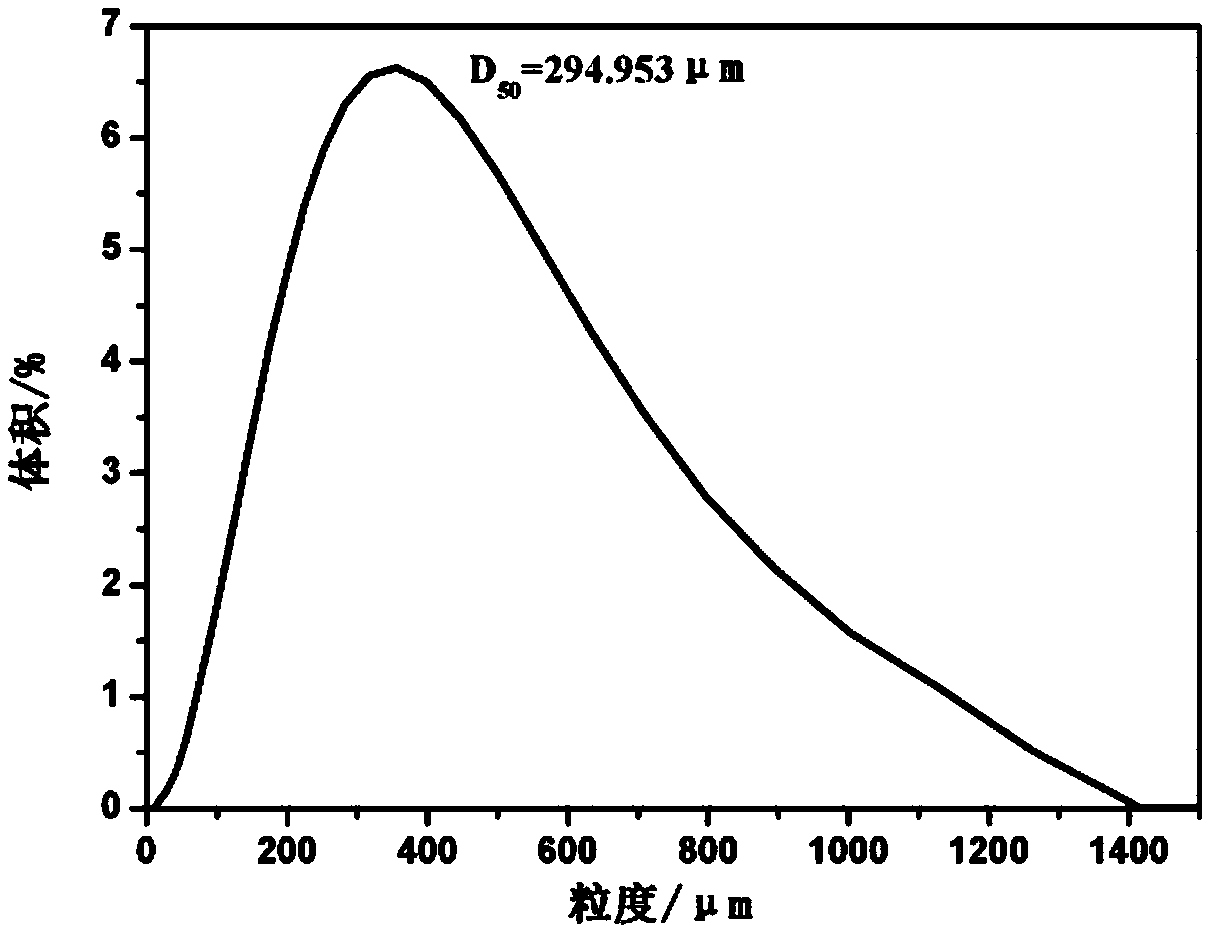

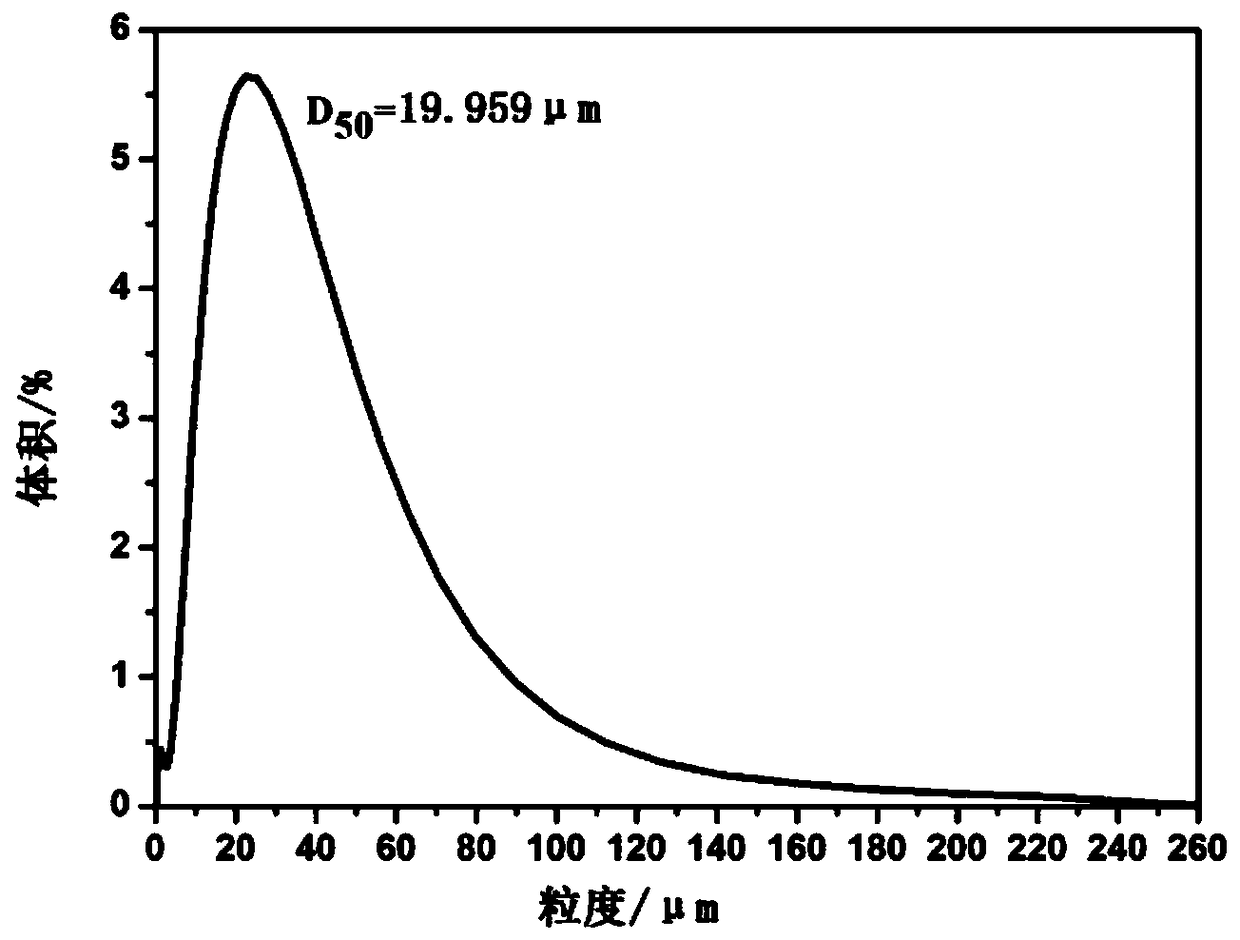

[0037] The particle size distribution of potassium nitrate after cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com