Potassium nitrate low-tower granulation method and potassium nitrate particles prepared thereby

A technology of potassium nitrate and granulation, which is applied in the field of potassium nitrate granules, which can solve the problems of uneven granulation, large particle size, and easily broken particles, and achieve the effect of less particle breakage, uniform particle size and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

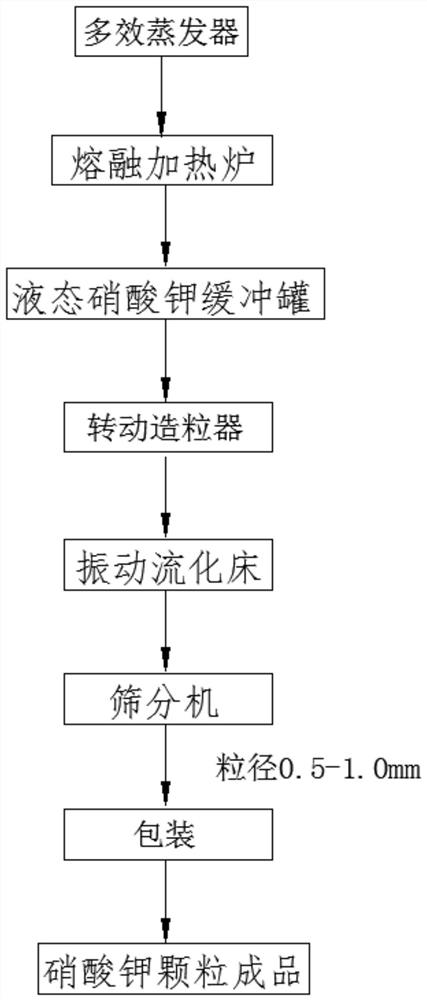

Method used

Image

Examples

Embodiment 1

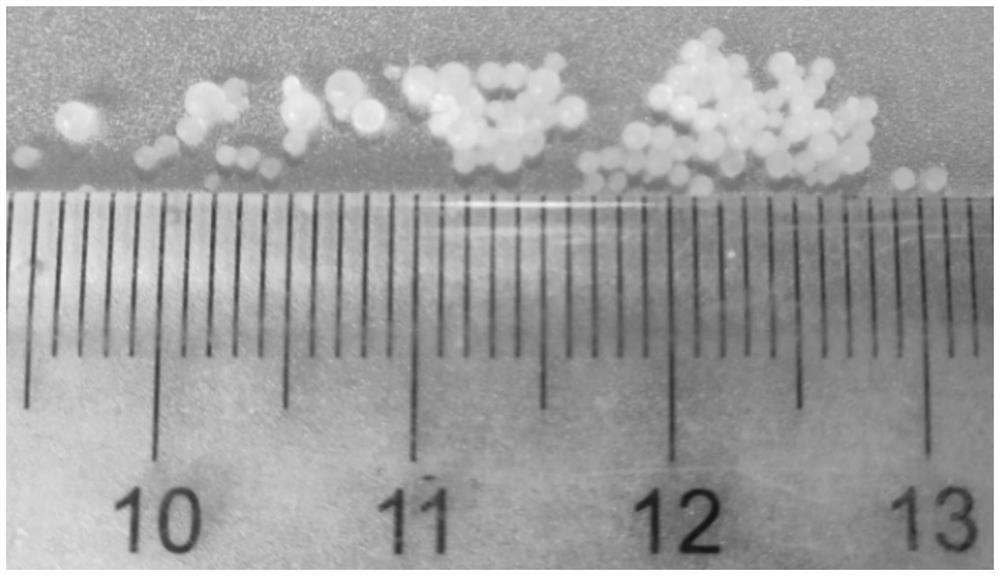

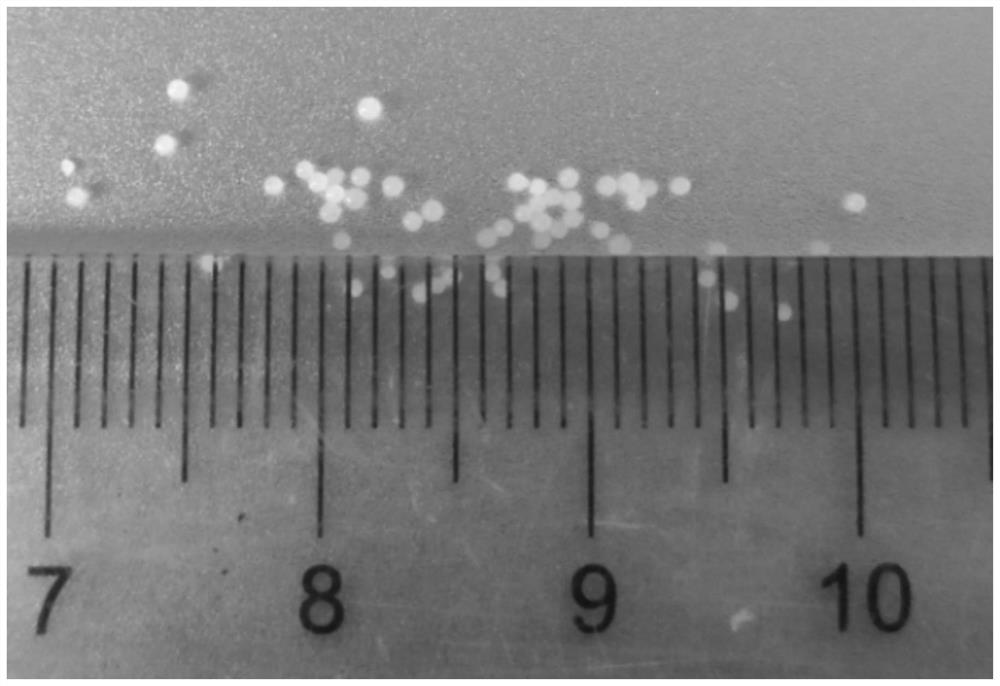

[0043] Put powdered potassium nitrate with a purity of 99.0% into a melting furnace for heating and melting, and keep stirring, control the heating temperature to 330°C, and stir for 10 minutes until the raw material is completely melted to obtain liquid potassium nitrate, and pass the liquid potassium nitrate through the delivery pipeline Transported to the upper part of the granulation tower with a tower height of 10 meters and heated to 330°C by a high-frequency induction heater in the rotary granulator, the liquid potassium nitrate is evenly dispersed and falls under the action of the granulation head of the rotary granulator, so that the nitric acid Potassium droplets are solidified and granulated into balls while falling inside the high-temperature prilling tower to form spherical potassium nitrate particles, which are dropped into the collection tank for collection. The temperature of the collected spherical potassium nitrate particles is 110°C , and cooled to 60°C throu...

Embodiment 2

[0045] Put powdered potassium nitrate with a purity of 99.4% into a melting furnace for heating and melting, and keep stirring, control the heating temperature to 340°C, and stir for 30 minutes until the raw material is completely melted to obtain liquid potassium nitrate, and pass the liquid potassium nitrate through the delivery pipeline Transported to the upper part of the granulation tower with a tower height of 10 meters and heated to 330°C by a high-frequency induction heater in the rotary granulator, the liquid potassium nitrate is evenly dispersed and falls under the action of the granulation head of the rotary granulator, so that the nitric acid Potassium droplets are solidified and granulated into balls while falling inside the high-temperature prilling tower to form spherical potassium nitrate particles, which are dropped into the collection tank for collection. The temperature of the collected spherical potassium nitrate particles is 110°C , and cooled to 70°C throu...

Embodiment 3

[0047] Put powdered potassium nitrate with a purity of 99.7% into a melting furnace for heating and melting, and keep stirring, control the heating temperature to 360°C, and stir for 15 minutes until the raw material is completely melted to obtain liquid potassium nitrate, and pass the liquid potassium nitrate through the delivery pipeline Transported to the upper part of the granulation tower with a tower height of 10 meters and heated to 330°C by a high-frequency induction heater in the rotary granulator, the liquid potassium nitrate is evenly dispersed and falls under the action of the granulation head of the rotary granulator, so that the nitric acid Potassium droplets are solidified and granulated into balls while falling inside the high-temperature prilling tower to form spherical potassium nitrate particles, which are dropped into the collection tank for collection. The temperature of the collected spherical potassium nitrate particles is 110°C , and cooled to 65°C throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com