Process for producing rice-shaped crystalline potassium nitrate by brine mixing method

A technology of potassium nitrate and brine mixing method, which is applied in the direction of preparation of alkali metal nitrate, purification of alkali metal nitrate, preparation and molding of alkali metal nitrate, etc. It can solve the problems of affecting product purity, limiting product use, and inconvenient use. Achieve the effects of not easy to agglomerate, wide range of uses, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

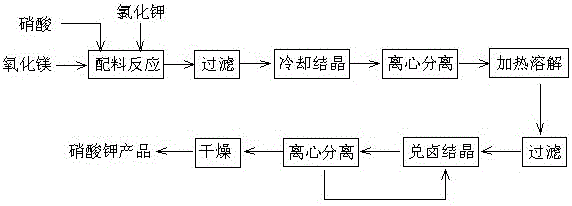

[0013] Combine now figure 1 The present invention is further described,

[0014] Preparation process of high-purity magnesium hydroxide

[0015] Include the following steps:

[0016] (1) Put nitric acid, magnesium oxide and potassium chloride into the reaction tank at the ratio of mass fraction 5:1:3, and then filter to remove insoluble impurities after the reaction;

[0017] (2) cooling and crystallizing the obtained filtrate, and centrifuging to obtain crude potassium nitrate;

[0018] (3) Add water to the obtained crude potassium nitrate, heat to dissolve, and filter to obtain a high-temperature solution of potassium nitrate; (4) Add the high-temperature solution of potassium nitrate to the cooled low-temperature solution of potassium nitrate in a mass ratio of 1:1 to 3 to crystallize At the same time, add potassium nitrate seed crystals into the crystallizer, control the solution temperature in the crystallizer at 30-50°C by controlling the amount of cooling water, stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com