Industrial sodium nitrate new product and its preparation method

A manufacturing method, the technology of sodium nitrate, is applied in the direction of preparation and molding of alkali metal nitrate, and the liquid is divided into beads and granulated. block, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

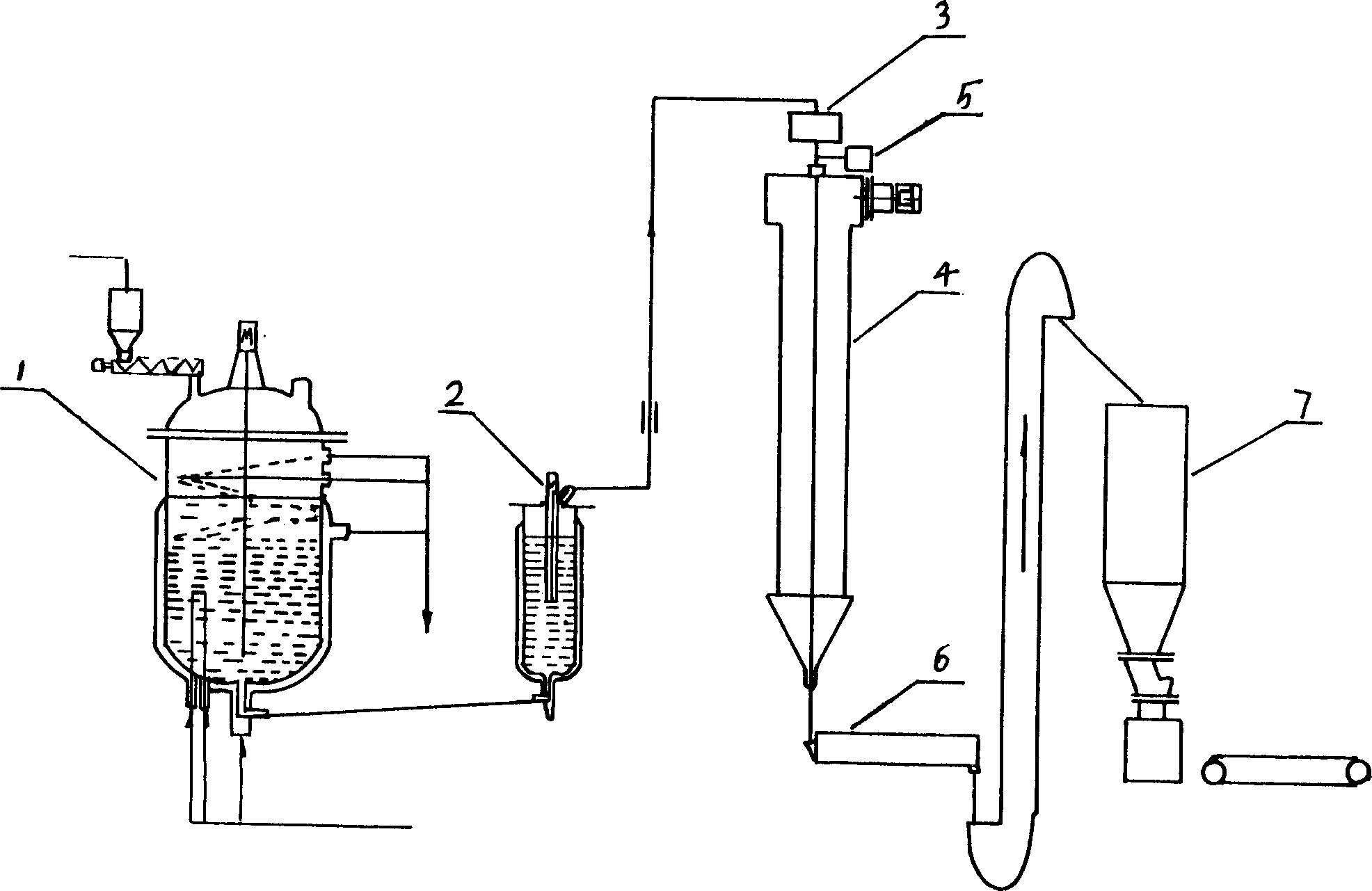

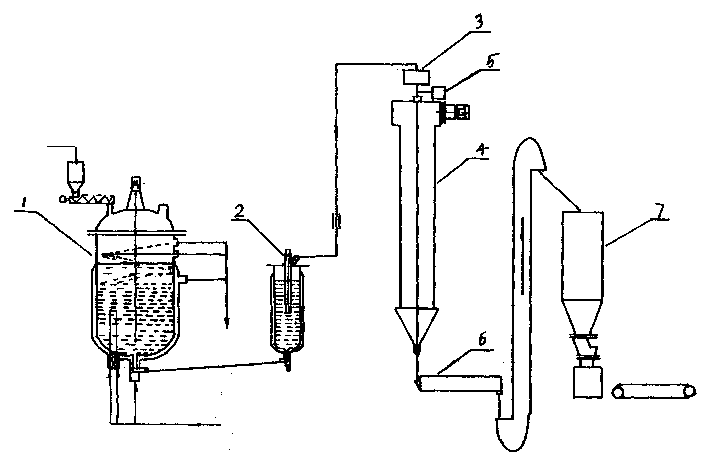

Image

Examples

Embodiment approach

[0023] The present invention is further stated below:

[0024] The industrial sodium nitrate product of the present invention is granular, and the individual shape of each particle is spherical, oval or other approximate shapes, and the particle diameter is preferably controlled at 0.5-3mm, such as its particle diameter is 0.5, 1, 1.5, 2, 2.5, 3, etc. , Of course, it can also be slightly larger or smaller than the above range. The moisture content of the above-mentioned granules is ≤0.5% (% on a dry basis), and it is ≤0.5%, that is, any value or interval value can be controlled within the range of 0-0.5%, and of course it is ≤0.1%, ≤0.05% better. The above-mentioned moisture content may also be affected by the processing environment (air humidity in the workshop) and the conditions in the packaging process.

[0025] The manufacture method of industrial sodium nitrate product of the present invention:

[0026] (1) take the industrial sodium nitrate product in the prior art a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com