Method for treating nitrite in industrial wastewater

A technology for nitrite and industrial wastewater, applied in the field of membrane separation, can solve the problems of low efficiency, secondary pollution, large investment, etc., and achieve the effects of high efficiency, low cost and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make it easier for those skilled in the art to understand the solution of the present invention, the technical solution of the present invention will be further specifically described in conjunction with specific embodiments.

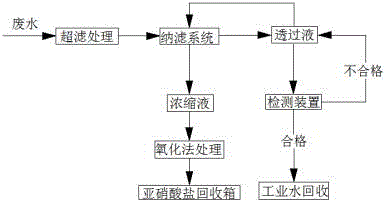

[0018] Such as figure 1 Shown, the present invention is a kind of treatment method of nitrite in industrial waste water, and treatment process is that waste water enters nanofiltration treatment after pretreatment (ultrafiltration treatment) removes the suspension of macromolecule, and concentrated solution is treated and recovered through oxidation process For nitrite, the permeate is recycled for use after repeated treatment several times and passed the inspection. The specific operation steps are as follows:

[0019] Step 1, the industrial wastewater is treated by ultrafiltration to remove suspended solids of macromolecules;

[0020] Step 2, the ultrafiltration membrane permeate from which macromolecules have been removed is proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com