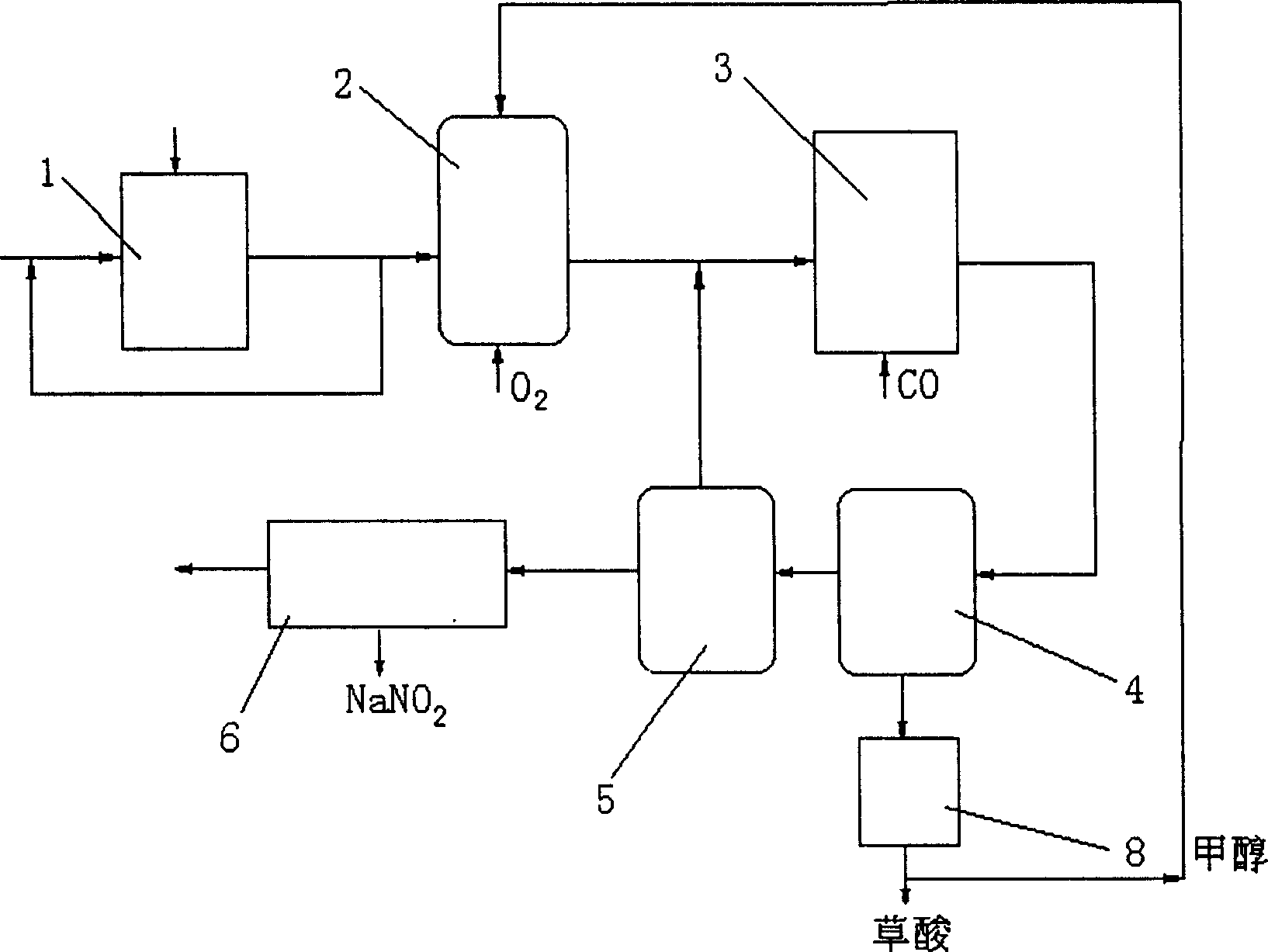

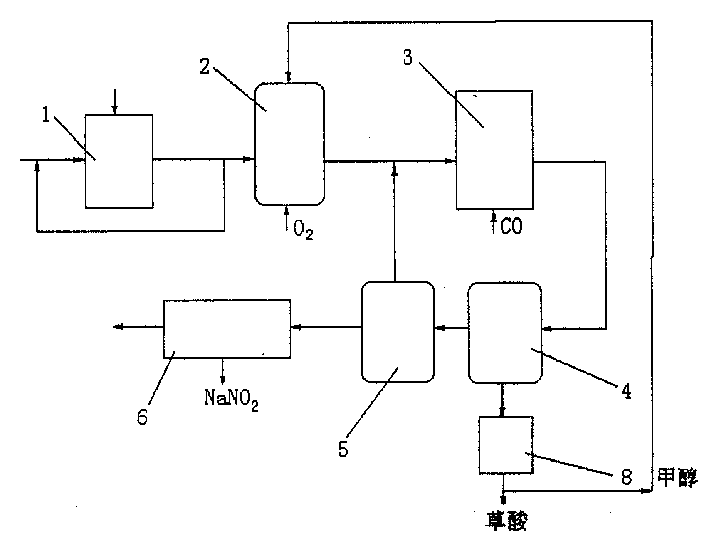

Method and device for producing oxalic acid and sodium nitrite

A technology of sodium nitrite and oxalic acid, which is applied in the reaction of nitrous acid and carbon monoxide to prepare carboxylic acids, nitrogen oxides/oxyacids, etc., can solve the problems of difficulty in popularization and application, difficulty in recovering NO, etc., and achieve huge economic and social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Obtain ammonia oxidation mixed gas by ammonia oxidation furnace 1, wherein:

[0047] NO: 16%; O 2 : 3.5%; N 2 : 56.5%; H 2 O: 24%;

[0048] Send the mixed gas into the oxidative esterification reactor 2, carry out oxidative esterification reaction with methanol aqueous solution and oxygen, the reaction temperature is 40°C, adjust the molar ratio of NO to oxygen to 1:0.25; the molar ratio of NO to methanol to 1:10 ; The mixed gas at the outlet of the oxidation esterification reactor 2 is mixed with CO with a content of 98%, and the mixed gas composition is: CH 3 ONO: 12%, CO: 15%, N 2 : 72%, N X o Y : 1%, then enter a coupling synthesis reactor 3, the temperature of the reaction is 140°C, and the reaction residence time is 1.5 seconds; the mixture is sent to the product condenser 4, and dimethyl oxalate is separated at a temperature of 110°C, and then conventional According to the method, oxalic acid and methanol are hydrolyzed in the hydrolysis reactor 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com