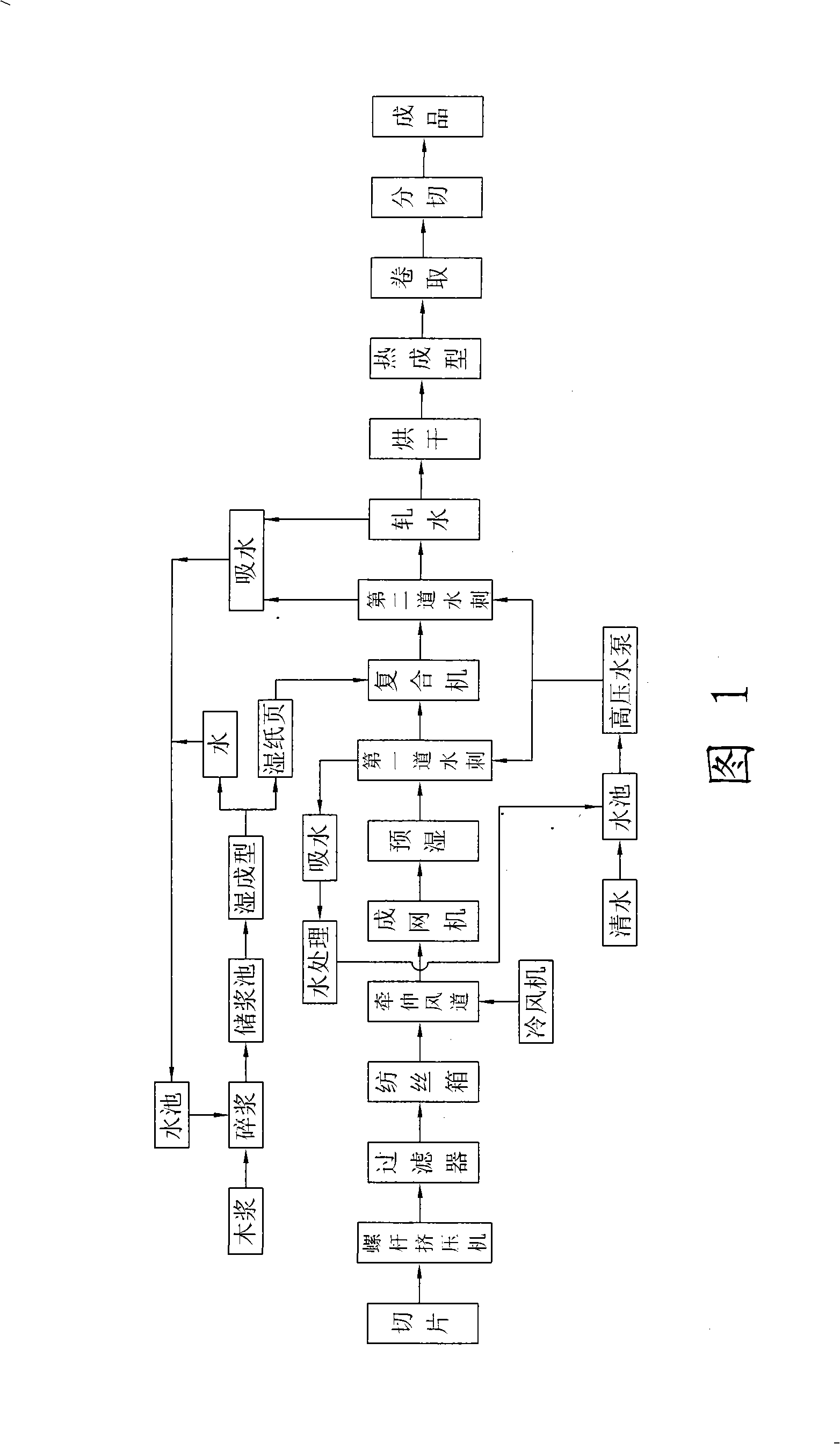

Production process of spun lace nonwoven fabric

A technology of spunlace non-woven fabric and production method, which is applied to non-woven fabrics, textiles and papermaking, etc., can solve the problems of inability to take into account product strength, hygroscopicity, hand feeling, etc., and achieves low production cost, high speed, and no lint loss. crumb effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A production method of spunlace non-woven fabrics, polyolefin fiber polypropylene fiber PP or polyester fiber polyester PET slices are fed into the hopper through a suction machine, enter a screw extruder, heat the slices to a temperature of 160-220°C, and pressurize to 5 The fluid in the molten state of ~20MPa uses a filter ≥ 200 mesh to filter out the impurities in the fluid and then flows into the spinning box, and enters the drafting air duct through the spinneret, and is cooled by 5 ~ 15°C freezing air. Perform drafting and cooling to make the spinning reach within 2 deniers, and the spun filaments reach the netting machine at a speed of >5000m / min, and spread into a uniform filament messy net. It is continuously output from the mesh curtain, sprayed and pre-wetted through the water spray pipe, and enters the spunlace machine for the first spunlace. The spunlace machine uses 2 to 3 spunlace heads with a pressure of 3 to 15MPa. After spunlace, the filament mesh has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com