Preparation method of structure-modified 1,2-polybutadiene rubber

A polybutadiene rubber and structure modifier technology, which is applied in the field of butadiene homopolymer preparation, can solve the problems of widening and reducing the molecular weight distribution, and the molecular weight of phosphorus-containing ligand products has not been seen, and achieve low viscosity , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Add the hydrogenated gasoline solution of butadiene in the stirred reactor that has been evacuated and filled with nitrogen, and then add the stoichiometric structural modifier liquid polybutadiene (molecular weight is 2×10 3 ) TBP substituted MoCl 5 (Mo / TBP=1:2 molar ratio), m-cresol substituted triisobutylaluminum Al(OPhCH 3 )(i-Bu) 2 . Heating in a water bath, the constant temperature is 60°C, the reaction time is 6h, the reaction is terminated with ethanol, the polymer is precipitated, washed and dried. However, Al / Mo=20 (molar ratio). The amount of structural modifier is 3% (mass ratio) of the amount of butadiene monomer.

[0068] Monomer conversion rate, polymer intrinsic viscosity, microstructure content, gel content, etc. are listed in Table 1.

[0069] Table 1 Butadiene monomer conversion rate, polymer structure

[0070] Monomer Conversion % [η] Mη×10 5 Mn×10 5 Mw / Mn l,2% Transl, 4% Gel% 87.9 4.53 7.38 3.68 2.3...

Embodiment 2

[0075] Add the hydrogenated gasoline solution of butadiene into the stirred reactor that has been evacuated and filled with nitrogen, and then add the polybutadiene of the stoichiometric structure modifier liquid hydroxyl end with a syringe; MoCl 3 (OC8H17) 2 (or TBP substituted MoCl 5 , Mo / TBP=1:2 molar ratio), m-cresol substituted triisobutylaluminum Al(OPhCH3)(i-Bu)2. Heating in a water bath, the constant temperature is 60°C, the reaction time is 6h, the reaction is terminated with ethanol, the polymer is precipitated, washed and dried. Among them, Al / Mo=30, Mo / Bd=4.0×10-4 (molar ratio). The amount of structural modifier is 3% (mass ratio) of the amount of butadiene monomer.

[0076] The monomer conversion, polymer intrinsic viscosity, gel content and microstructure of the two catalysts are listed in Table 2.

[0077] Table 2 Butadiene monomer conversion rate, polymer structure

[0078] sample number Molybdenum catalyst Monomer Conversion % [η] Mn×10 ...

Embodiment 3~ Embodiment 7

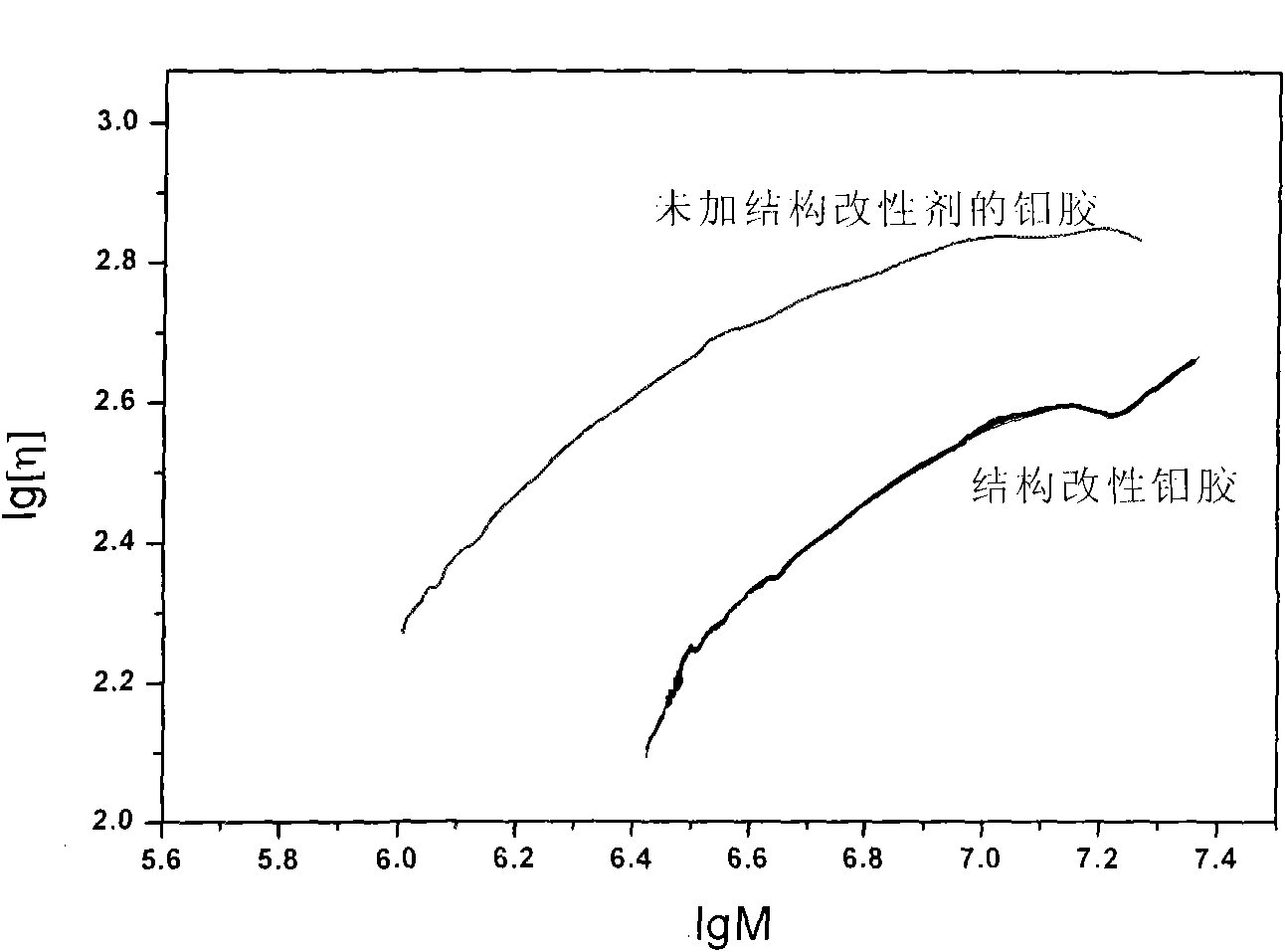

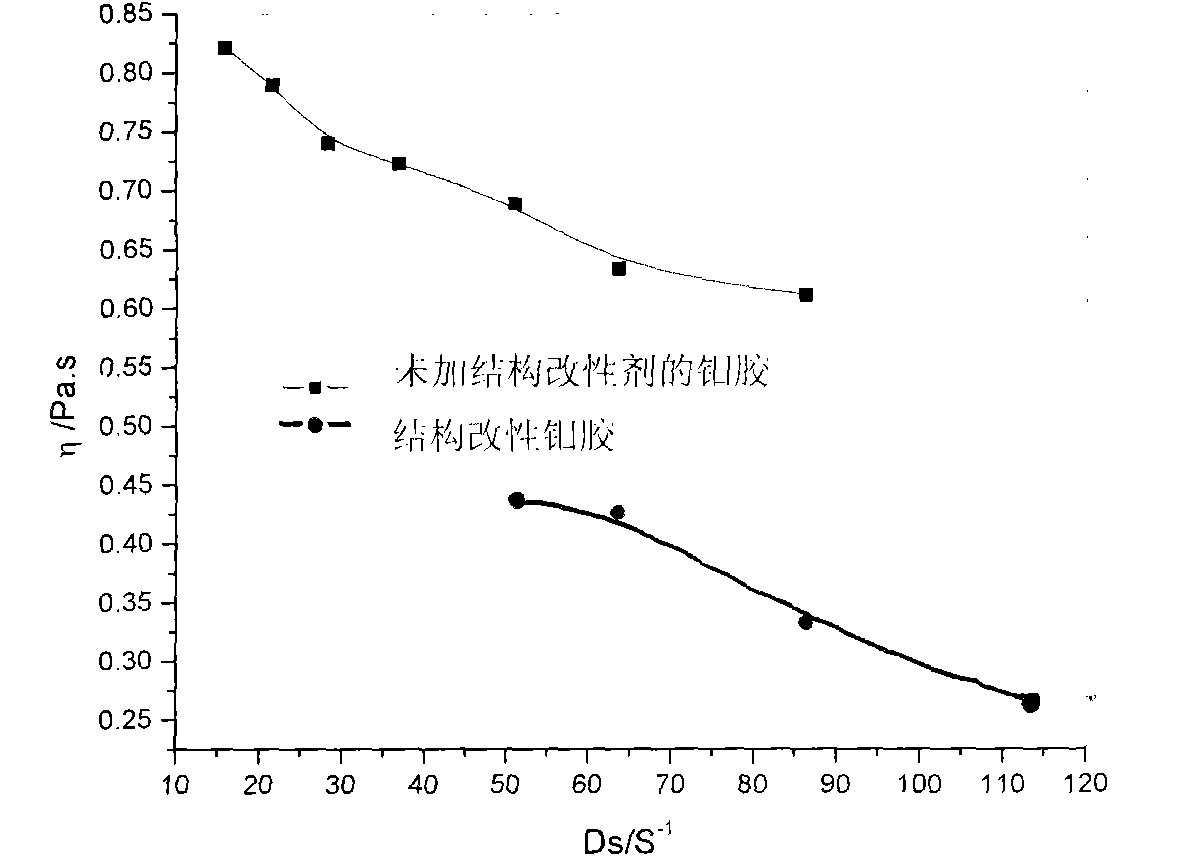

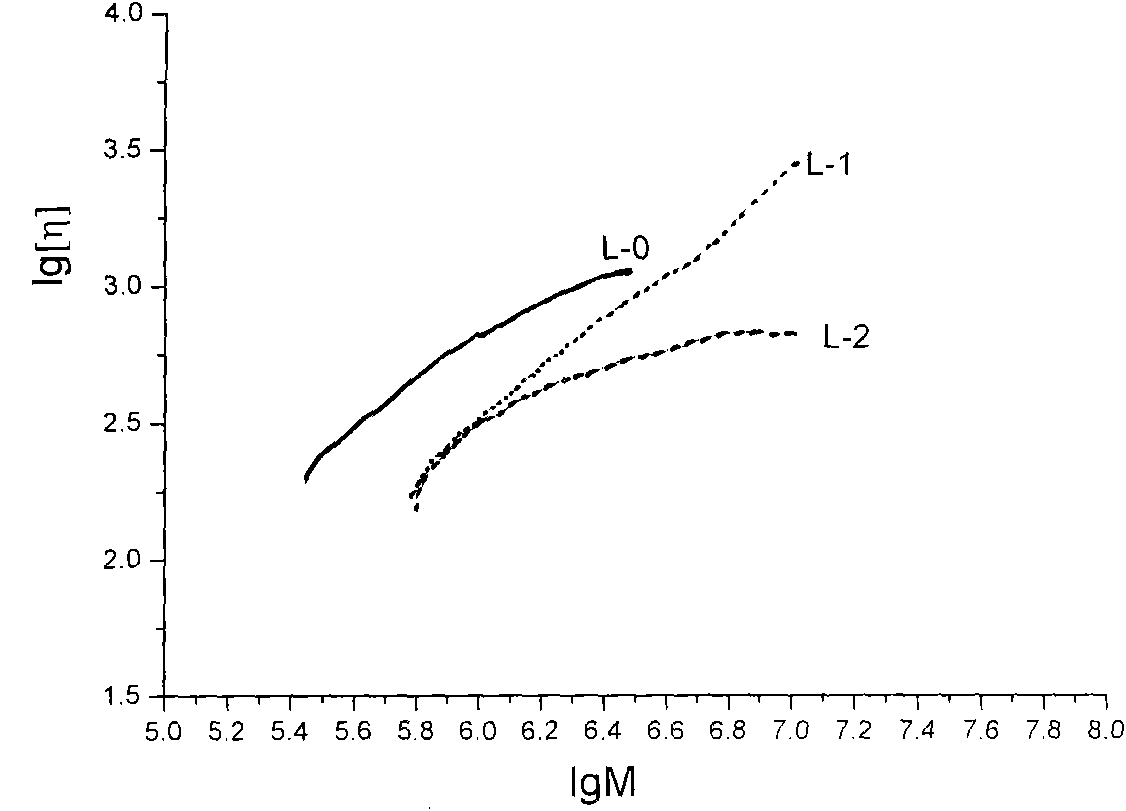

[0082] Add PB structural modifiers with different molecular weights of 3% mass of butadiene monomer mass to TBP-substituted MoCl 5 (Mo / TBP=1:2 molar ratio), m-cresol substituted triisobutylaluminum Al(OPhCH 3 )(i-Bu) 2 Catalyzed butadiene monomer polymerization system, where Mo / Bd=2×10 -4; Al / Mo=20; TBP / Mo=2 (the above are molar ratios); [Bd]=0.14g / ml, reacted at 60°C for 6h, and the conversion rate of the obtained product was greater than 95%. The molecular weight of gained polymer and its distribution, gel content and its cyclohexane solution (3g / 100ml) viscosity that measure solution at 25 ± 0.2 ℃ with the rotational viscometer of NXS-11A are as shown in table 3:

[0083] Table 3 Mo-based 1,2-PB molecular weight and its distribution and solution viscosity prepared by structural modifiers with different molecular weights

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com