Treating process for multiple exhaust gases

A technology for treating process and industrial waste gas, which is applied in gas treatment, separation methods, nitrogen oxides/oxygen-containing acids, etc., can solve the problems of potential environmental impact, immature core technology, and increased energy cost Secondary pollution, low operating cost and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

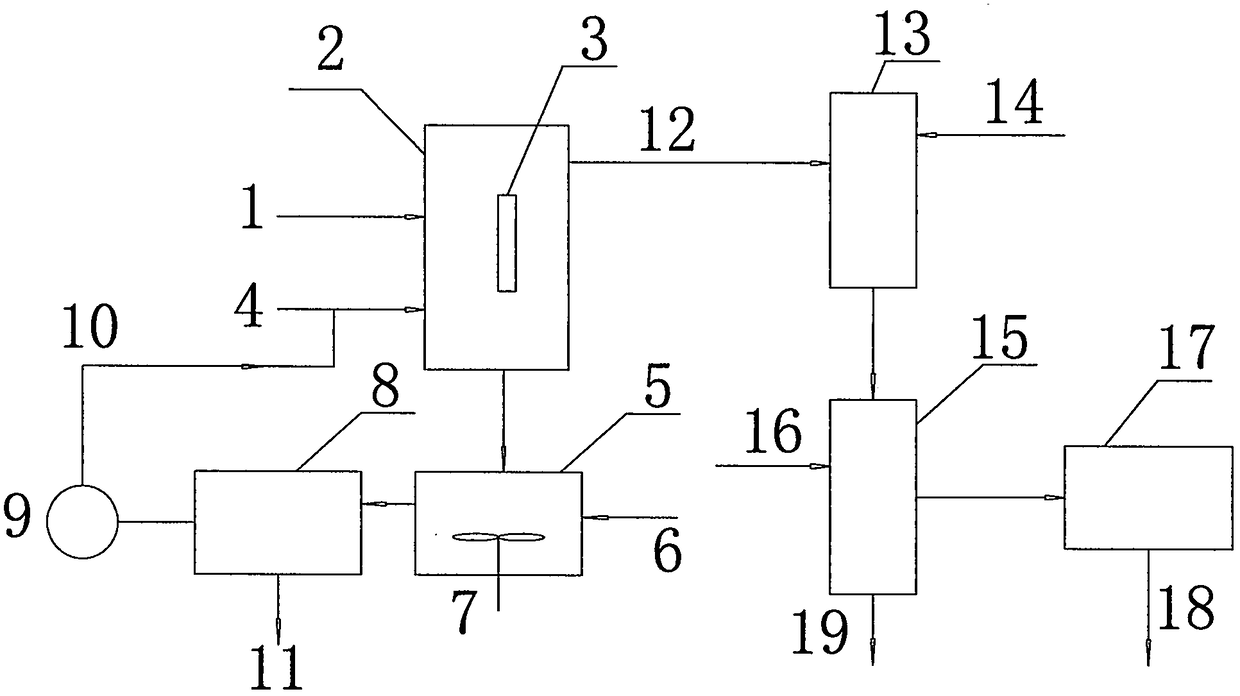

[0014] A variety of waste gases 1 are introduced into the absorption reactor 3 in the waste gas treatment device 2 , the ammonia reagent 4 is introduced, and the reacted liquid substances are collected in the rich liquid pool 5 .

[0015] The metal oxide 6 is introduced into the rich solution pool 5 and mixed with a stirrer 7 . The mixed slurry is sent to the solid-liquid separation device 8 .

[0016] The separated ammonia-containing liquid is sent to the first absorption reactor 3 together with the amino reagent 4 through the pump 9 and the pipeline 10; the separated carbon-containing compound 11 solid is dried, packaged and sold.

[0017] The purified waste gas 12 enters an oxidation reactor 13 and passes through a strong oxidant 14 . The exhaust gas enters the second absorption reactor 15 again, and passes through the alkaline liquid 16, and the neutralization reactant flows into the solid-liquid separation device 17. The nitrogen-containing compound solid 18 is dried, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com