Fly ash for cement production or concrete admixture, and production technology thereof

A technology for fly ash and concrete, applied in cement production, sustainable waste treatment, solid waste management and other directions, can solve the problems of low utilization rate of fly ash, unstable fly ash quality, and poor recycling performance, etc. Achieve the effect of saving energy, being beneficial to environmental protection and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

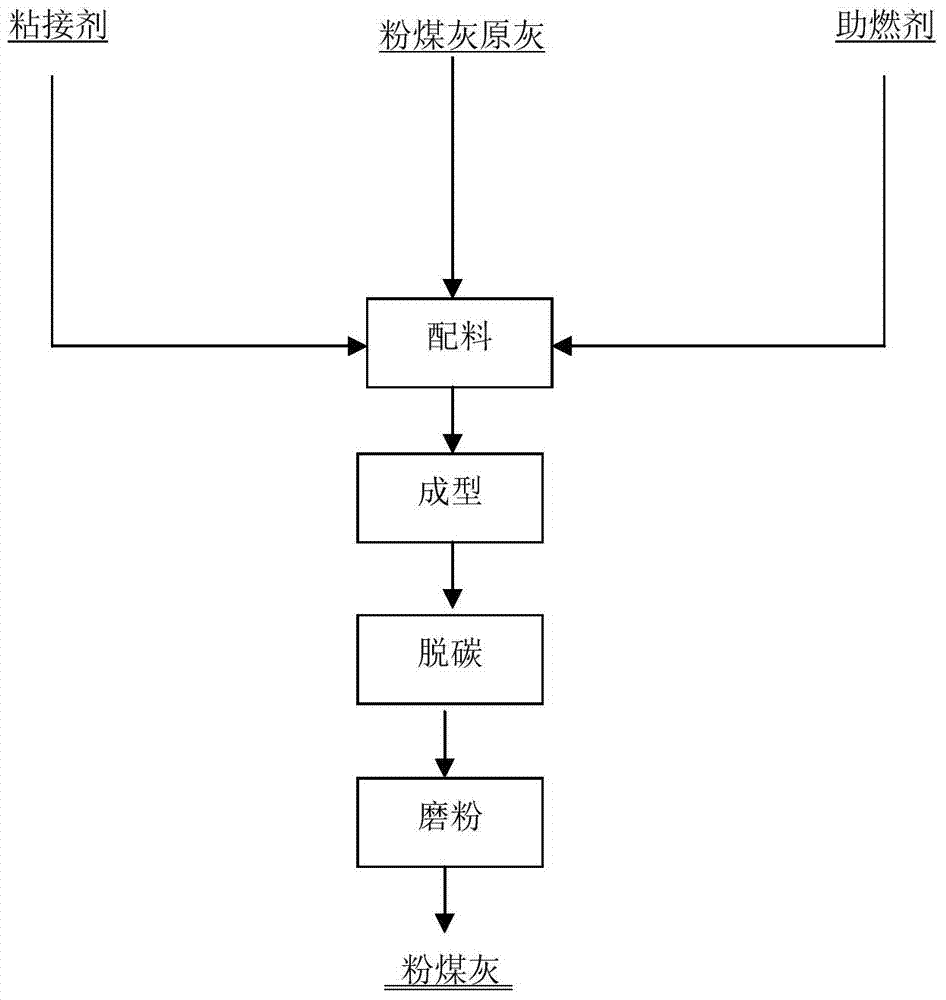

Method used

Image

Examples

Embodiment 1

[0038] The preparation of the fly ash as admixture in the cement production of embodiment 1

[0039] In this embodiment, fly ash is prepared from the raw ash of a power plant in Cheng'an County, Handan City, Hebei Province. The main component of the raw ash of fly ash is: SiO 2 50.6%, Al 2 o 3 27.2%, Fe 2 o 3 7.0%, SO 3 0.3%, loss on ignition 8.2%; binder is bentonite produced in Yongnian County, Handan City; combustion enhancer is Henglitai brand coal-saving combustion enhancer produced in Langfang. The mixing ratio of each raw material is 91.0% of raw fly ash, 8.8% of binder, and 0.2% of combustion enhancer. Mix the above three raw materials evenly, press them into Ф10mm×15mm pellets with a 290-type static pressure ball, add them to a 0.6m×1.2m×2.5m square shaft kiln, and bake at 800±30°C for 1 hour. The fired pellets are ground with TCQ-750*900 ball mill for 0.5 hours, and the quality of fly ash is inspected as follows: loss on ignition 0.8%, water content 0.3%, sulfu...

Embodiment 2

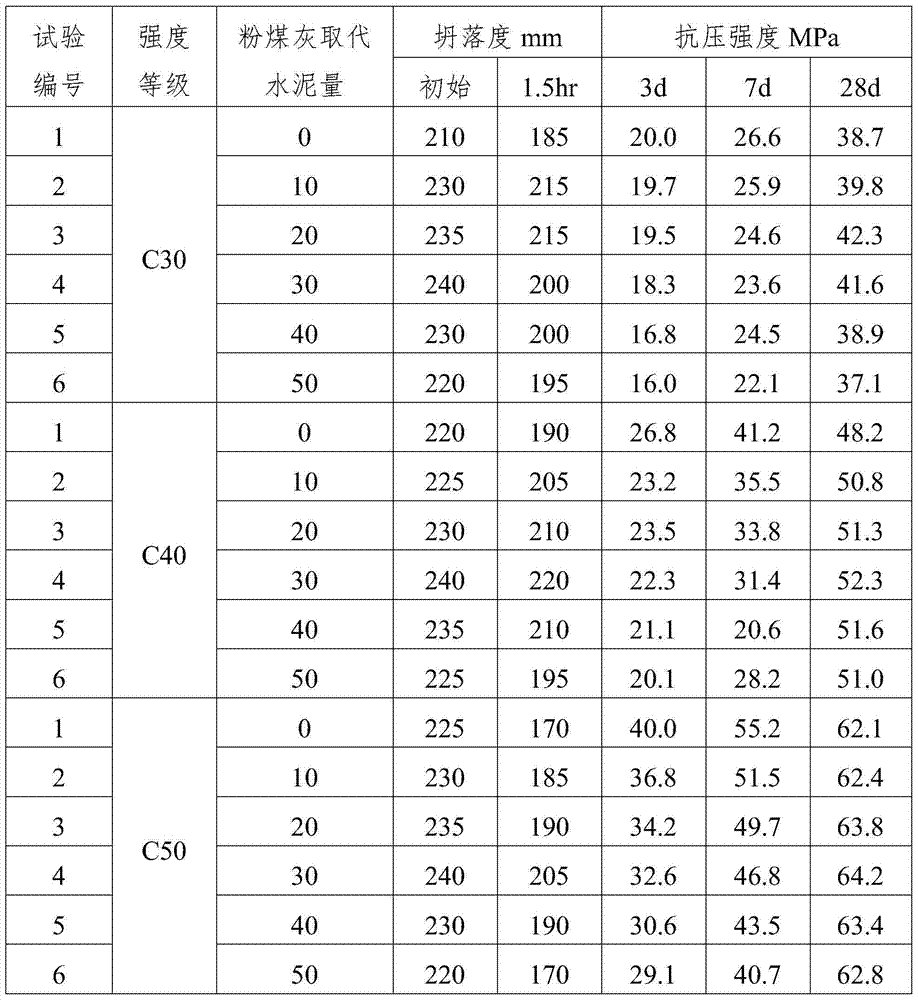

[0040] Embodiment 2 The preparation of I level mixing concrete and mortar with fly ash finished product

[0041] This embodiment utilizes the raw ash of the ash storage field in Daqiao Town, Dongjiao, Jinan City, Shandong Province to prepare fly ash. The main component of the fly ash raw ash is: SiO 2 50.6%, Al 2 o 3 27.1%, Fe 2 o 3 7.1%, SO 30.4%, CaO 3.3%, loss on ignition 8.8%, moisture 12.1%. The adhesive is industrial-grade sodium carboxymethylcellulose CMC produced in Leling City, Dezhou, and the combustion enhancer is HY-type multifunctional high-efficiency coal-burning combustion enhancer produced in Linyi City, Shandong Province. The blending ratio of each raw material is 99.5% of raw fly ash, 0.3% of binder, and 0.2% of combustion enhancer. Mix the above three raw materials evenly, form balls with a disc, put them into a small open hearth furnace, and bake at 650-850°C for 2.5 hours. After firing, the pellets were ground with a ball mill for 1 hour, and the qu...

Embodiment 3

[0042] Embodiment 3 I level mixes concrete and the preparation of fly ash finished product for mortar

[0043] In this embodiment, the wet-discharged fly ash from the No. 2 ash yard of Fenyi Power Plant in Jiangxi Province is used as raw ash to prepare fly ash. The main components of the raw ash are: SiO 2 50.3%, Al 2 o 3 25.1%, Fe 2 o 3 8.1%, CaO 4.3%, SO 3 1.3%, loss on ignition 11.3%. The adhesive uses fulvic acid produced in Pingxiang, Jiangxi, and the combustion aid uses HZ-618 combustion-supporting and coal-saving agent produced in Changsha. The blending ratio of each raw material is 92.5% of raw fly ash, 7% of binder, and 0.5% of combustion enhancer. Mix the above three raw materials evenly, form into balls with a double-roller briquetting machine, put them into a small open hearth furnace, and bake at 750±30°C for 1 hour. The fired pellets are ground with a ball mill for 1 hour, and the quality of the finished fly ash is inspected as follows: 3.6% sieved by a sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com