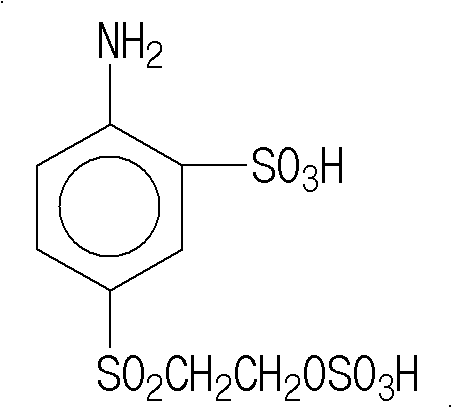

Preparation process of 4-beta-sulfatoethylsulfonyl aniline-2-sulfonic acid

A technology based on sulfuric acid and ester aniline, applied in the field of preparation of dye intermediates, can solve the problems of large amount of waste acid, non-compliance, environmental pollution, etc., and achieve excellent results in energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of sulfonated para-ester, comprising the steps of:

[0030] a, chlorosulfonation reaction of acetanilide: in reaction tank, add 1180kg of chlorosulfonic acid, then add 275kg of acetanilide, temperature is controlled below 15 ℃, stir well, be warming up to 60 ℃, react 3 hours, obtain feed liquid (1 ). In the dilution tank, add 3000kg of crushed ice and 1000L of water, add the feed liquid (1) under stirring, and dilute the temperature at 0-10°C to obtain the feed liquid (2), filter the feed liquid (2) with a solid-liquid separator to obtain Chlorosulfonate filter cake;

[0031] b. Reduction reaction

[0032] Add the chlorosulfonate filter cake obtained in step a to the sodium bisulfite solution containing 220kg, stir evenly, control the temperature at 25-30°C, use 40% sodium hydroxide solution to maintain pH = 7-7.5, and react for 2 hours , after the reaction is completed, the reduction reaction solution is obtained;

[0033] c. Condensation react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com