Efficient denitrifying device of circular fluidized bed boiler

A circulating fluidized bed and boiler technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of blocking the air gap of catalytic substances, shortening the life of catalytic substances, and reducing denitrification efficiency, so as to promote reduction, Simple structure, effect of reducing nitrogen oxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

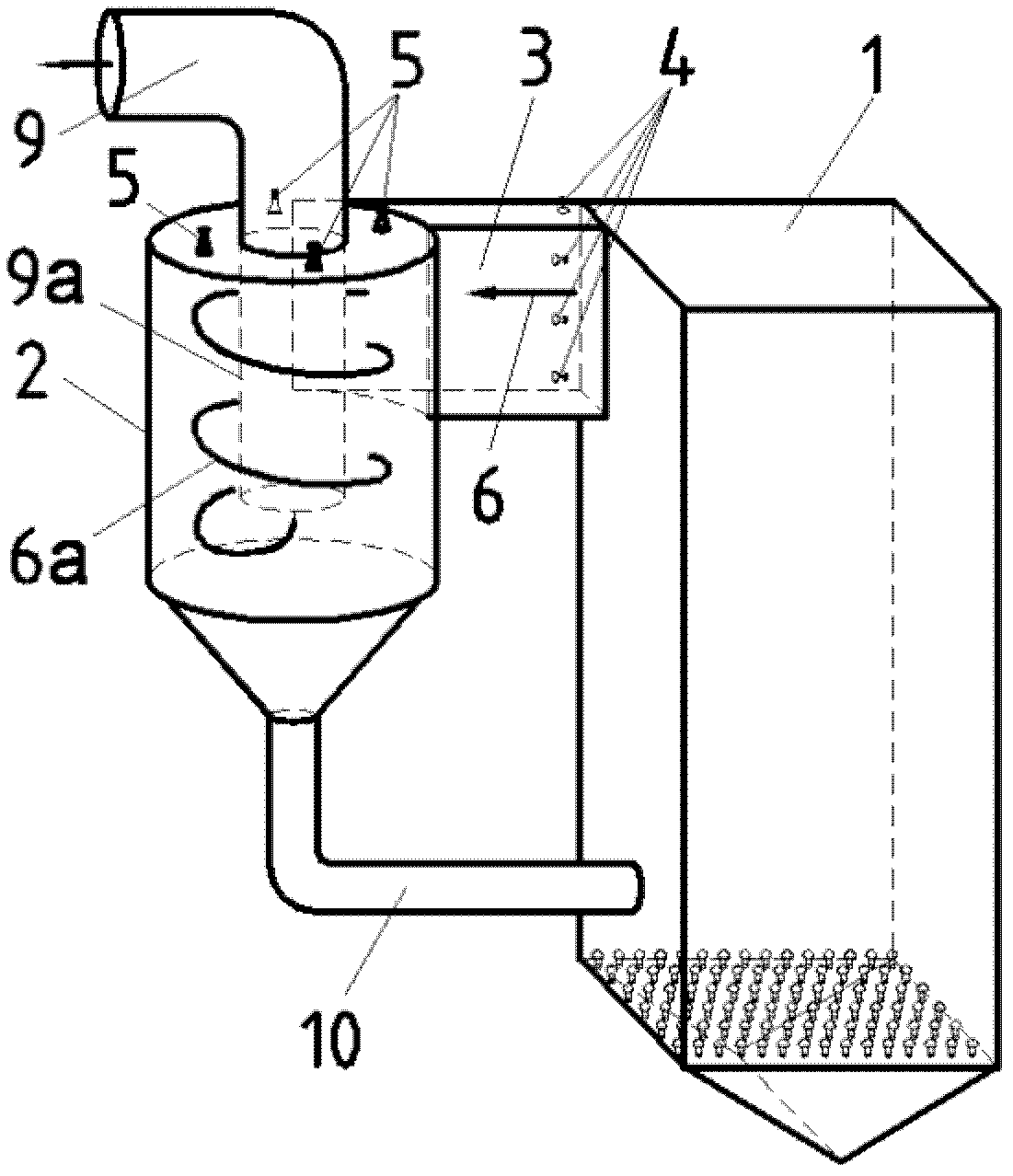

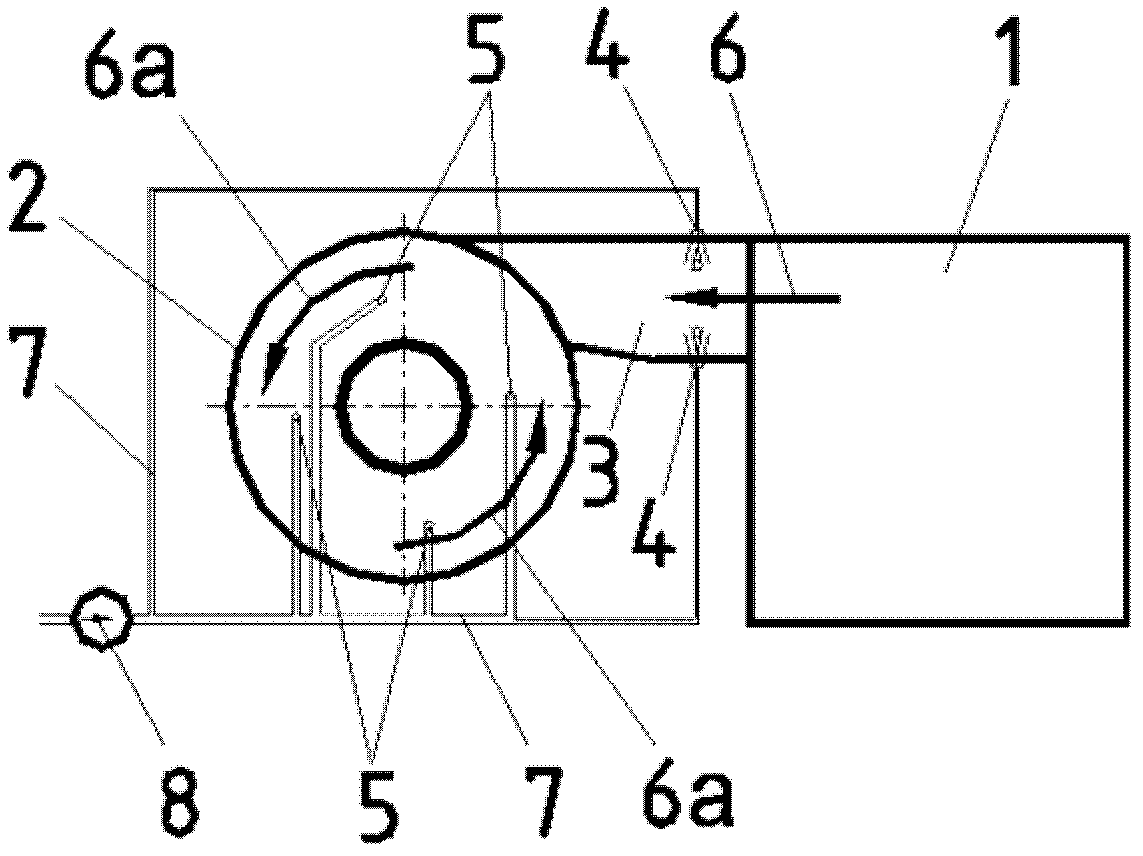

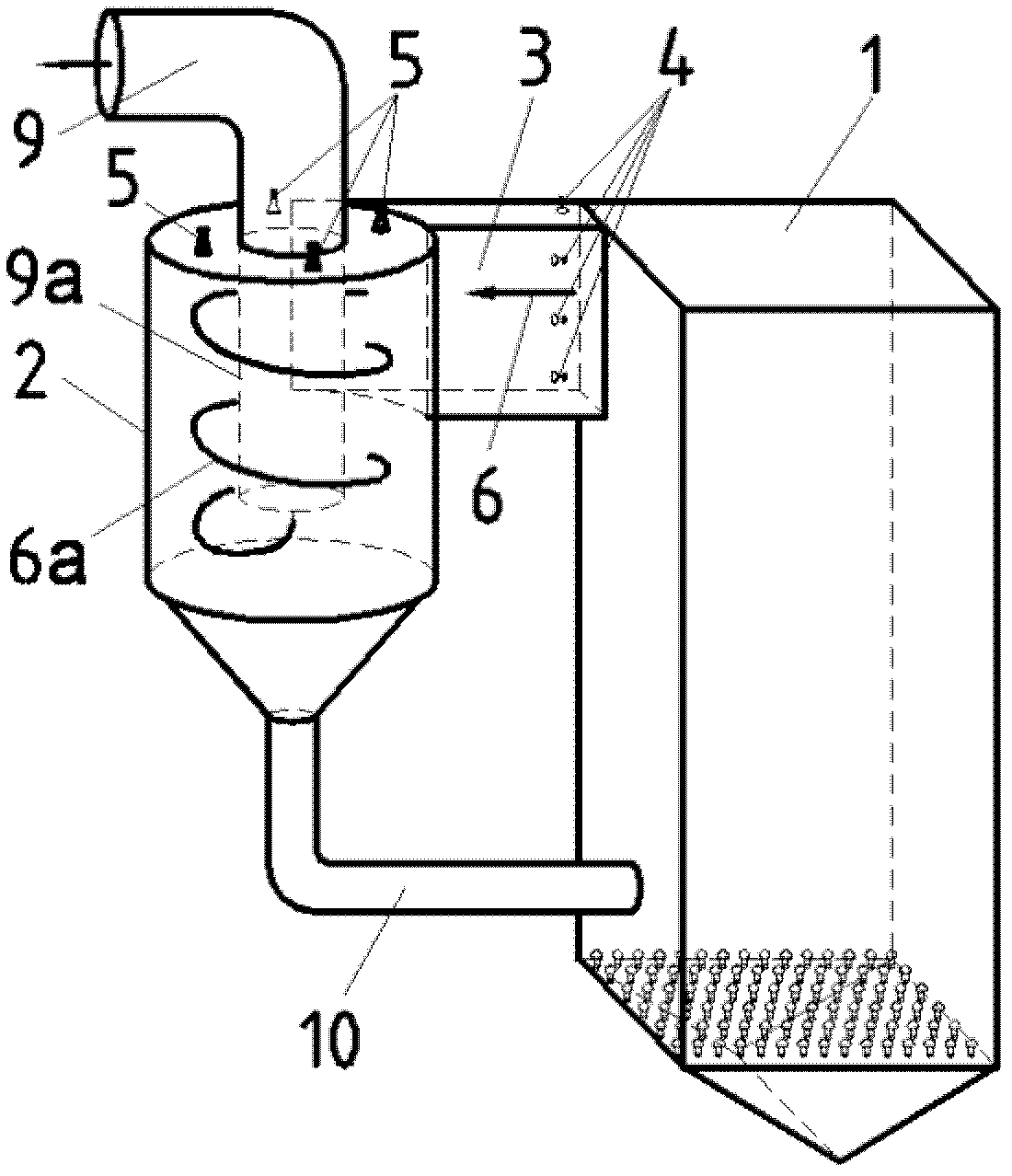

[0018] figure 1 , 2 A working principle diagram of a high-efficiency denitrification device for a circulating fluidized bed boiler is shown. In the figure, the denitrification device adopts a cyclone separator 2, which is connected tangentially to the boiler exhaust duct 3 of the circulating fluidized bed boiler 1, and a smoke return pipe connected to the circulating fluidized bed boiler 1 is provided at the lower part. Road 10, the upper part is provided with a flue outlet 9, and the bottom part of the flue outlet 9 is provided with an inner flue 9a extending into the cyclone separator 2. Four first denitration agent nozzles 4 for injecting denitration agent into the boiler flue exhaust duct 3 are arranged on the boiler flue exhaust duct 3 . Between the outer casing 2 of the cyclone separator and the inner flue 9a, four second denitrification agent nozzles 5 for spraying denitrification agent into the cyclone separator 2 are arranged at the top of the formed annular cavity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com