Ultralow-emission nitrogen oxide biomass chain boiler

A nitrogen oxide and chain boiler technology, applied in the boiler field, can solve the problems of nitrogen oxide environmental hazards, large-scale industrial production, large-scale application obstacles, etc., to reduce the content of nitrogen oxides, ensure the demand, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with a preferred embodiment.

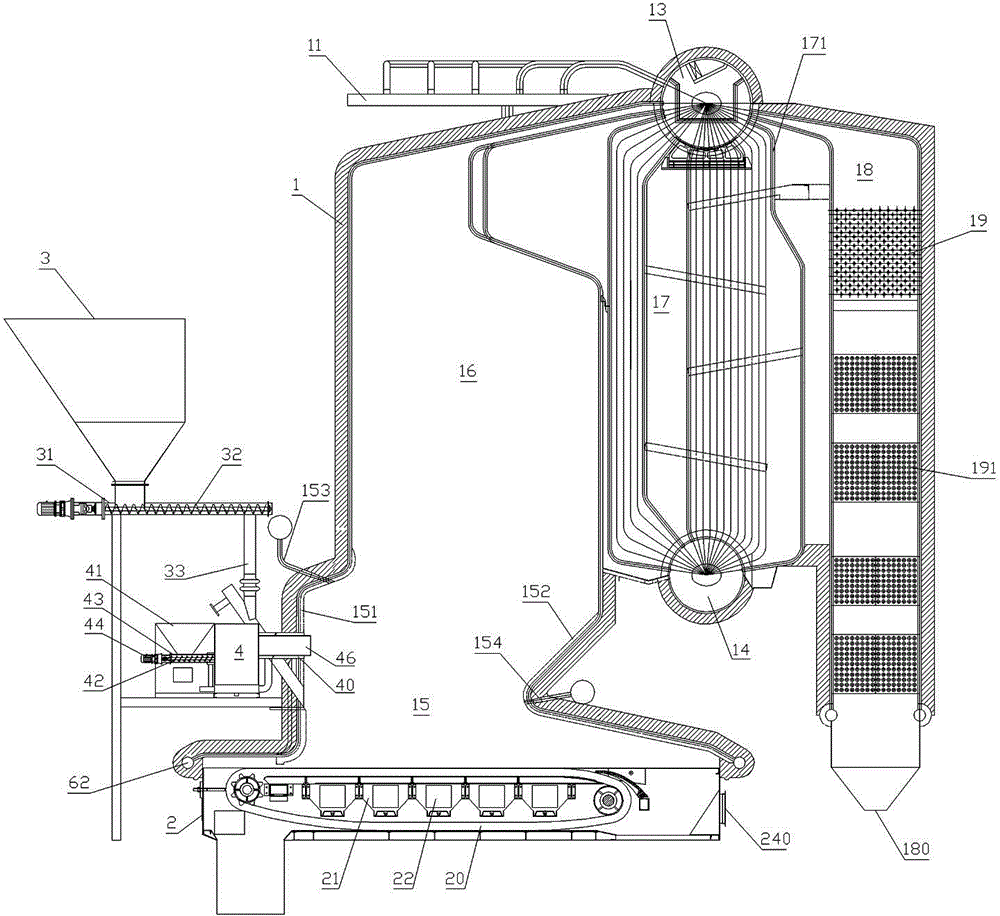

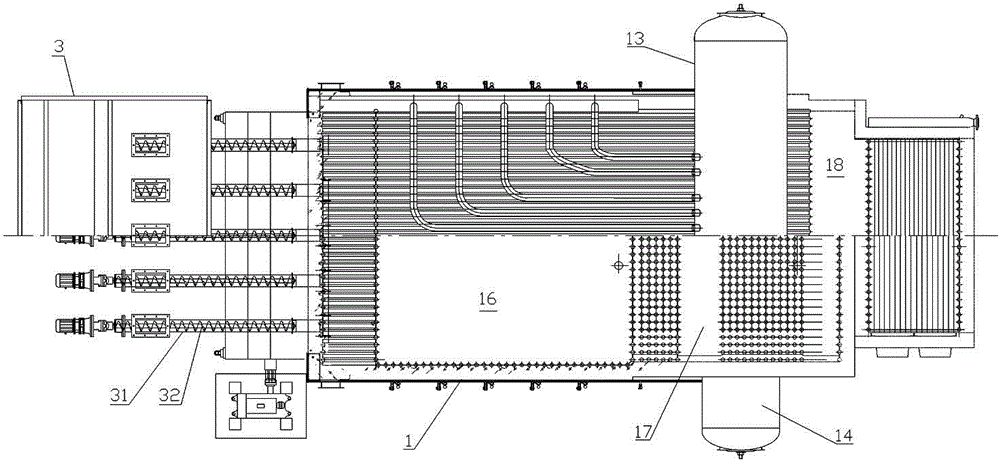

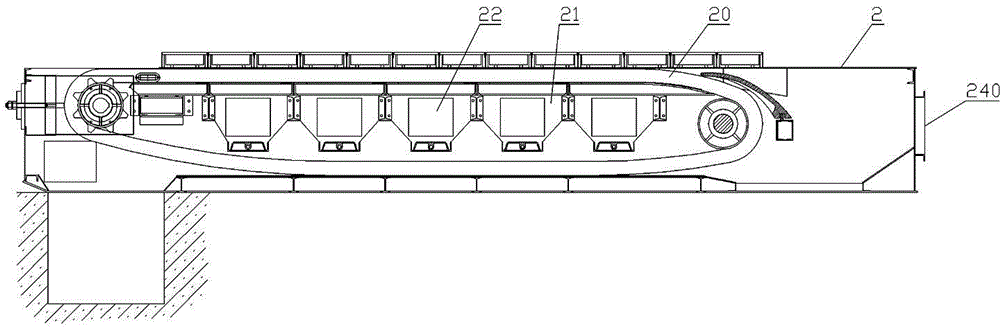

[0027] refer to Figure 1 to Figure 5 , an ultra-low emission nitrogen oxide biomass chain boiler, which includes a boiler body 1, a chain grate and a screw feeder.

[0028] The boiler body 1 is provided with an upper header 11 , a lower header 12 , an upper drum 13 and a lower drum 14 .

[0029] The upper header 11 and the lower header 12 are connected through a membrane water wall to form the lower furnace 15 and the upper flue gas radiation chamber 16. The boiler body 1 has a front arch 151 and a rear arch 152 at the front end and rear end of the furnace 15 respectively. .

[0030] The upper drum 13 and the lower drum 14 are placed in the flue gas convection box 17, and the flue gas convection box 17 is provided with a convection tube bundle 171, and the two ends of the convection tube bundle 171 are respectively connected to the upper drum 13 and the lower drum 14 , the flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com