Built-in biomass gasification combustion hot water boiler

A biomass gas and biomass technology, which is used in combustion equipment, solid fuel combustion, water heaters, etc., can solve problems such as energy waste, simple structure of water heaters, and hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

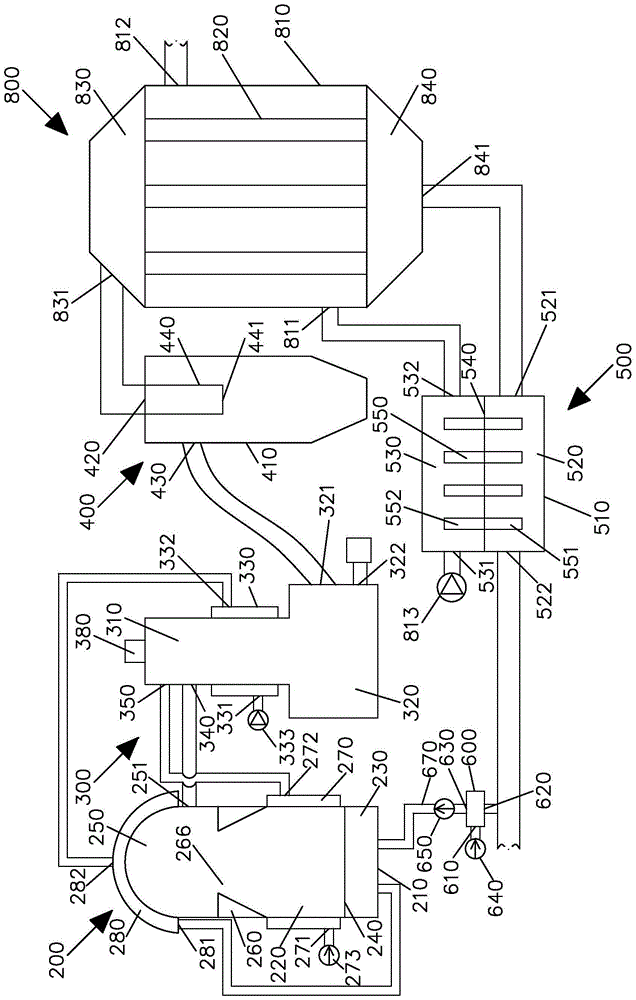

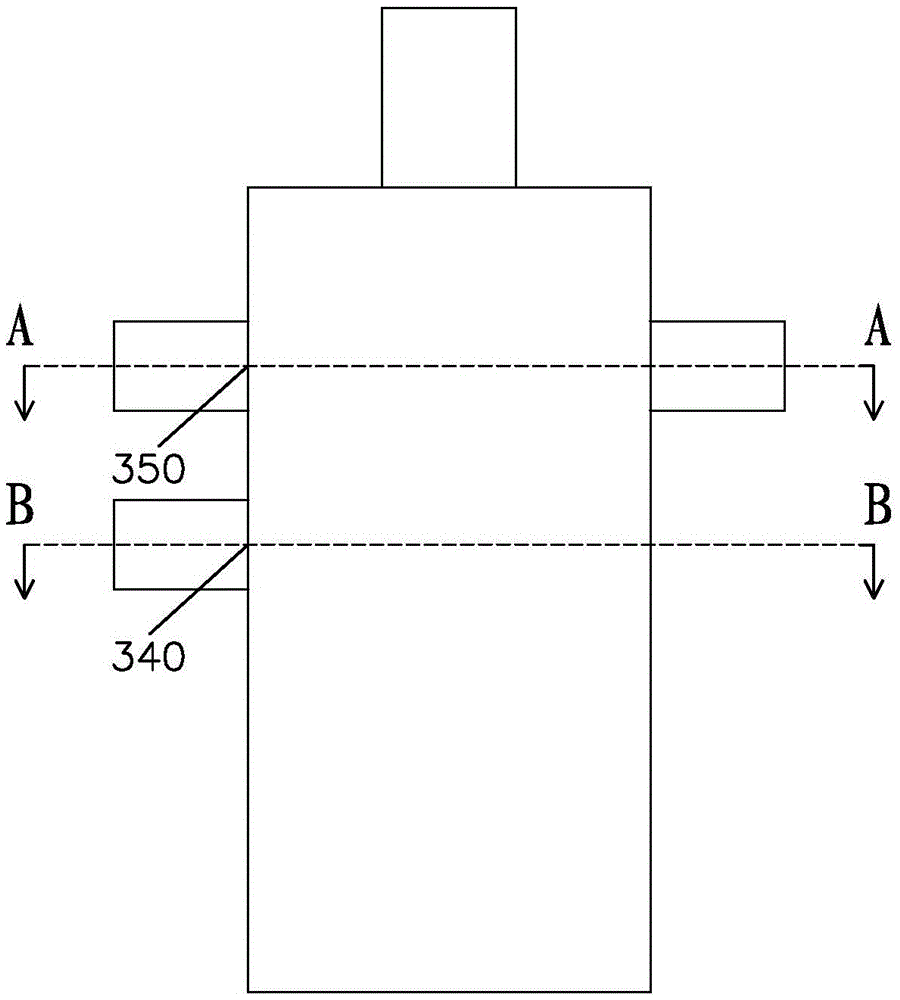

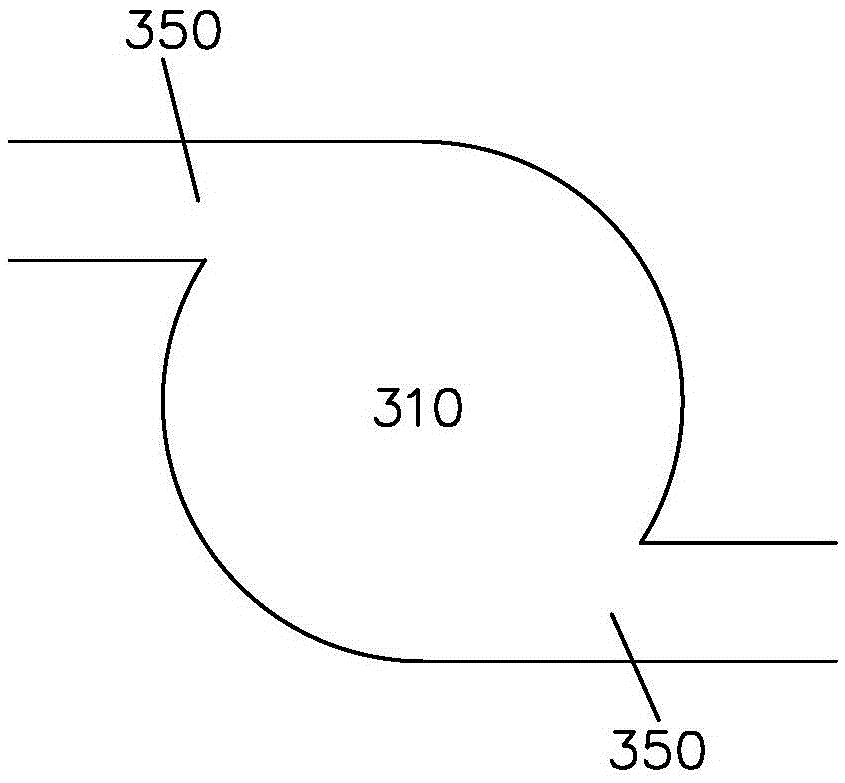

[0053] Please refer to figure 1 , according to an embodiment of the present invention, the built-in biomass gasification combustion hot water heater includes: a biomass gasification device 200 , a combustion chamber 300 and a water heater 800 .

[0054] The biomass gasification device 200 is used to generate biomass gas. Such as figure 1 As shown, the biomass gasification device 200 includes a device body 210, a fire grate 240 that is arranged inside the device body 210 and divides the inside of the device body 210 into a gasification reaction chamber 220 in the middle and an air chamber 230 in the lower part. The inside of the device body 210 is divided into a gas storage chamber 250 at the upper part and a fire wall 260 at the gasification reaction chamber 220 at the middle, and a wind blowing wall arranged around the outer wall of the device body 210 and located at the outside of the gasification reaction chamber 220. The sleeve 270 , and the first water sleeve 280 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com