Inside-mixing type reducing agent atomizing spray gun for SNCR (Selective Non-Catalytic Reduction) denitration process

An atomizing spray gun and reducing agent technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as leakage, late start of denitration technology, and single structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

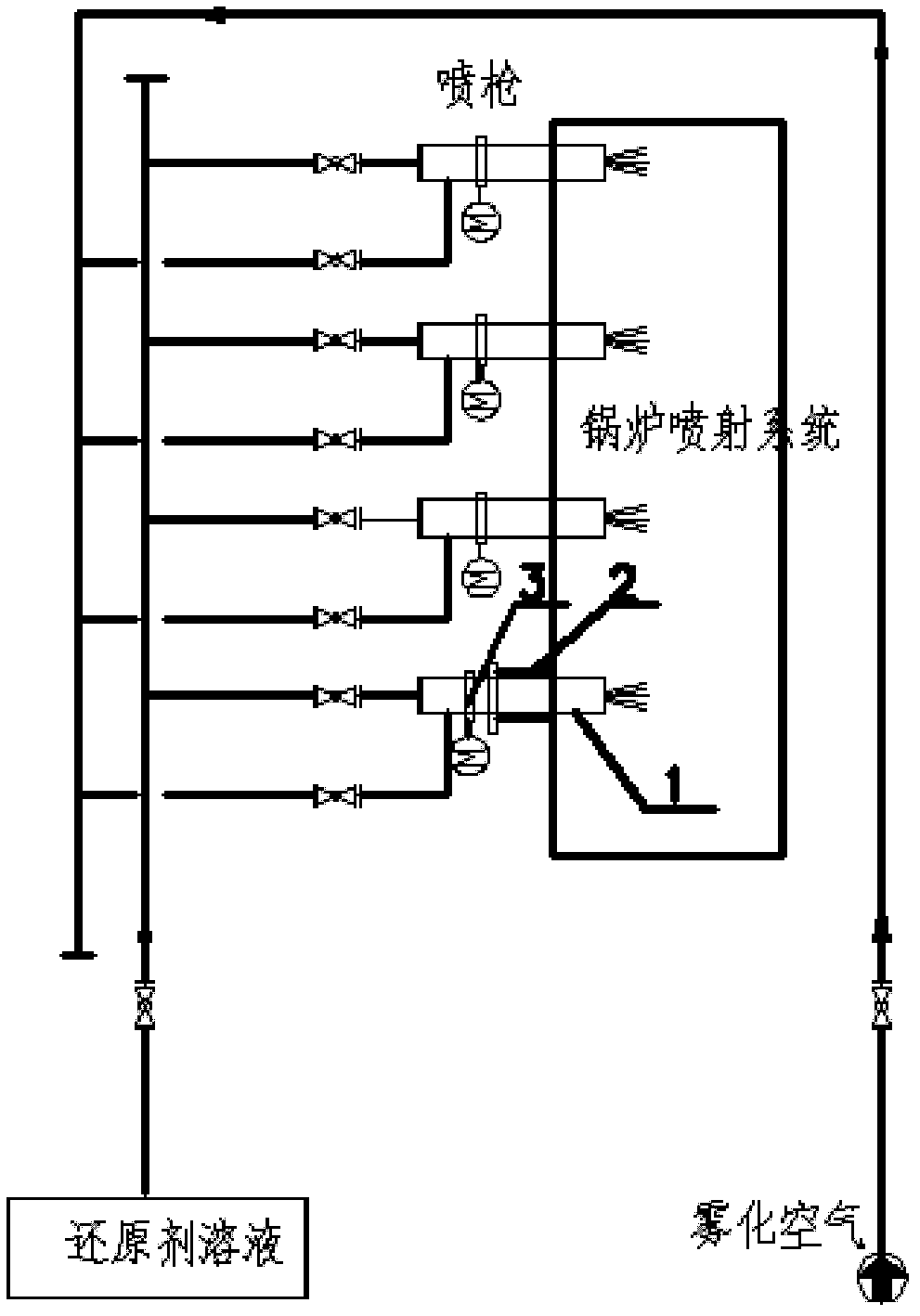

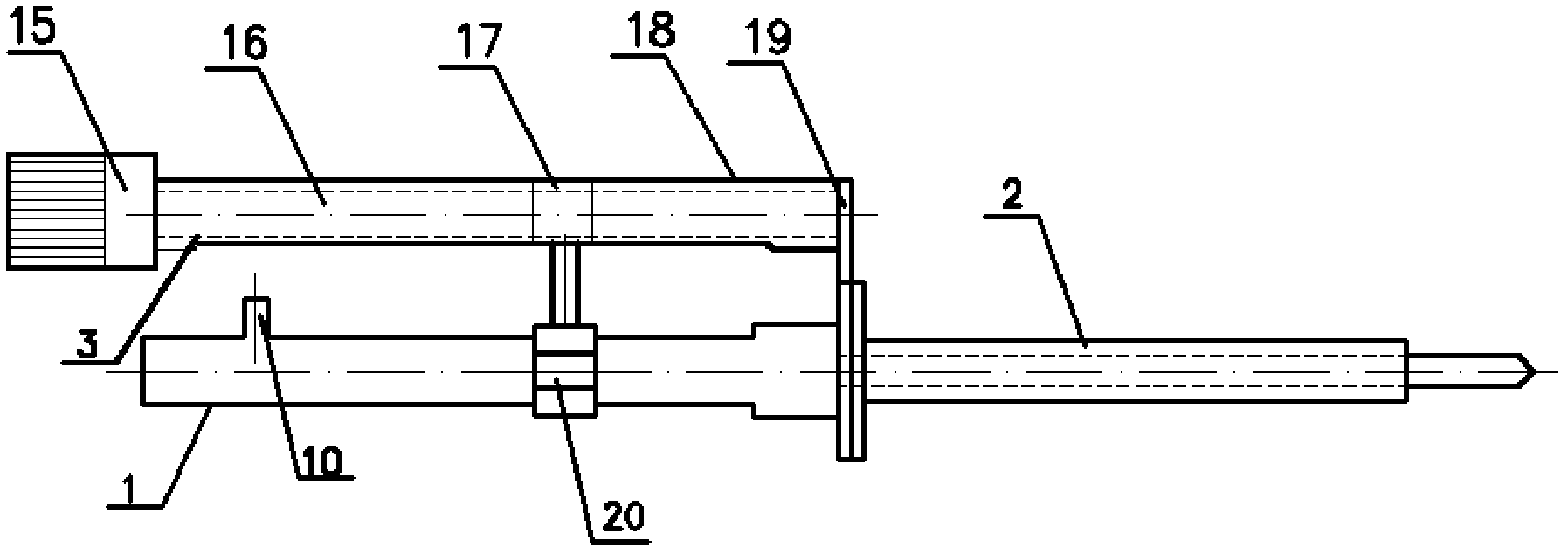

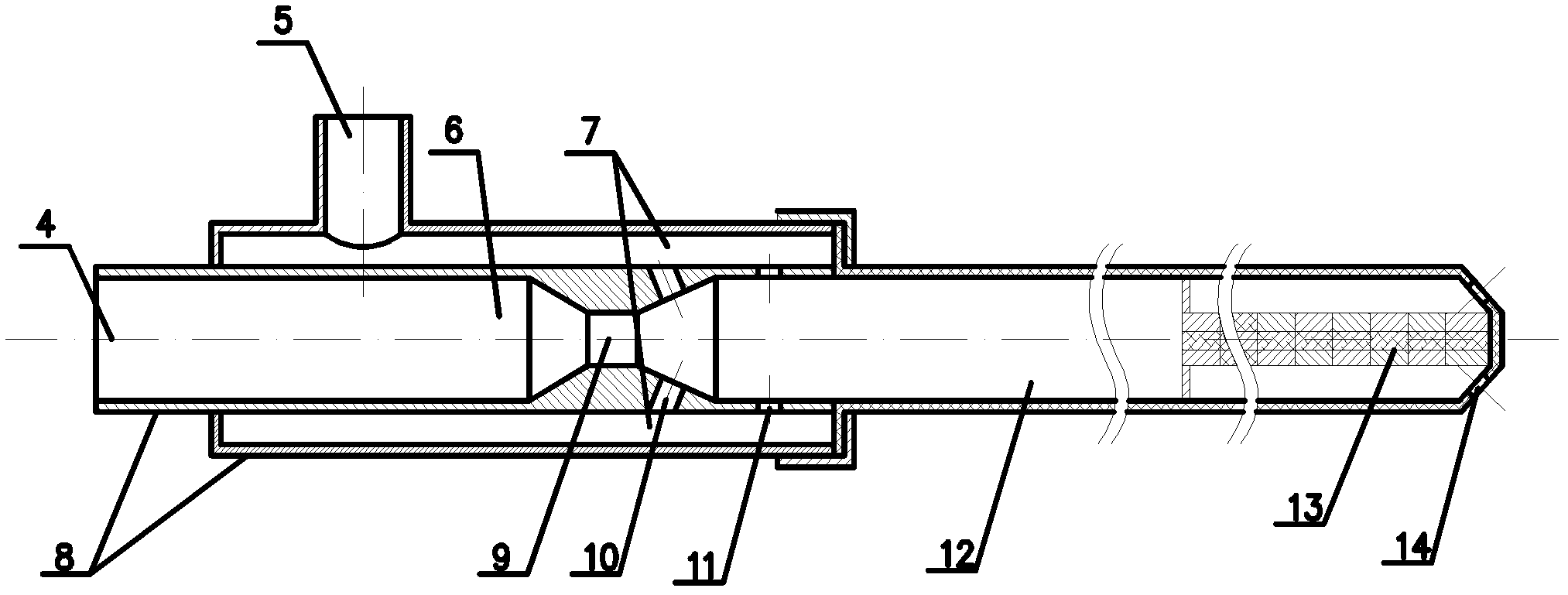

[0018] Embodiment: a kind of internal mixing type reductant atomizing spray gun for SNCR denitrification process, such as figure 1 , figure 2 and image 3 As shown, it includes a spray gun sleeve (2), an electric propulsion device (3) and a spray gun (1). The spray gun sleeve (2) is installed on the outer wall of the boiler and communicates with the boiler furnace. The spray gun sleeve (2) is inclined downward. It forms an included angle of 5-15° with the horizontal plane; the electric propulsion device (3) is fixedly connected with the spray gun (1), and the electric propulsion device (3) is fixedly connected with the spray gun sleeve (2).

[0019] The electric propulsion device (3) is a reciprocating linear electric drive mechanism, including a drive motor (15), a screw mandrel (16), a nut (17), a clamping jaw (20), an outer sleeve (18) and the mounting flange (19), the power shaft of the driving motor (15) is fixedly connected with the screw mandrel (16), the screw nut (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com