Integrated method for simultaneously realizing denitrification, desulfurization and heavy metal removal from flue gas, and special equipment suitable for the method

A technology for desulfurization, denitrification, and heavy metal removal, applied in the field of flue gas purification, can solve the problems of large one-time investment, no mercury removal, and large system resistance, and achieve the effects of simple system, high recovery rate, and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

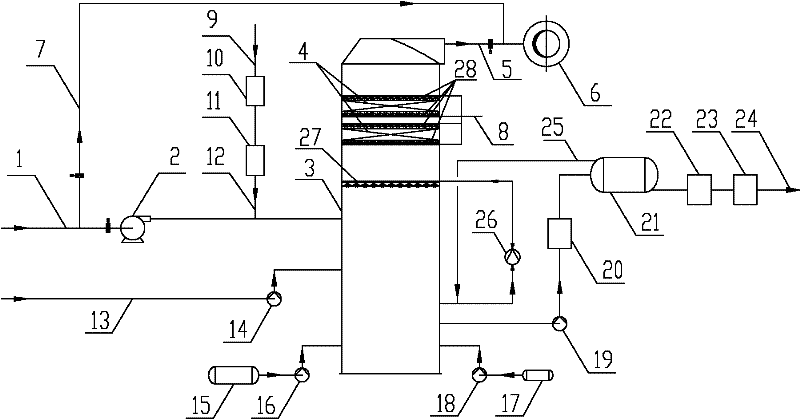

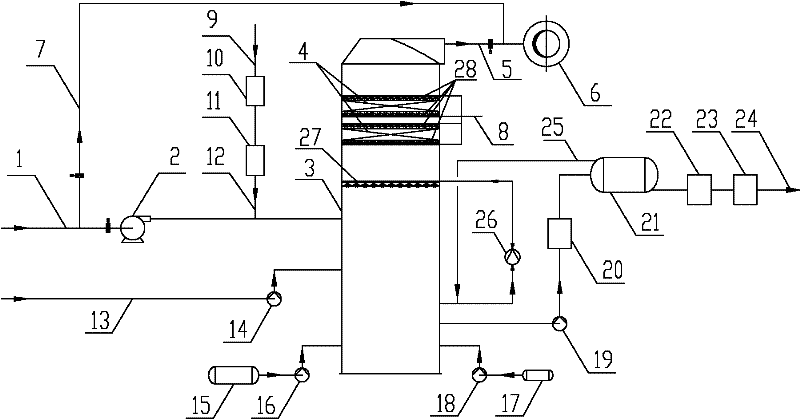

[0034] The method and special equipment of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but this is not intended to limit the present invention.

[0035] figure 1 It is the structural representation of the special equipment of the present invention, utilizes figure 1 The integrated method of flue gas desulfurization, denitrification and heavy metal removal of the equipment shown is as follows: the original flue gas is pressurized by the booster fan 2, enters the original flue 1, and before entering the absorption tower 3, a certain amount of A large amount of ozone oxidizes the nitric oxide in the original flue gas into high-valent nitrogen oxides (NOx) such as nitrogen dioxide, and then the original flue gas enters the absorption tower 3 from the original flue 1 inlet. After entering the absorption tower 3, the original flue gas flows upward through the spray layer 27, and the SO in the flue gas 2 , N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com