Valve device with cylinder stop mechanism of ic engine

A technology for cylinder block and internal combustion engine, applied in the direction of cylinder, cylinder head, mechanical equipment, etc., can solve problems such as adverse effects, increase the time difference and residue of solidification time of light alloy casting parts such as aluminum alloys, etc. The effect of eliminating the solidification time difference and reducing the amount of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 of the present invention will be described with reference to the drawings.

[0026] First, the structure of the cylinder block 10 and its peripheral structure, which are objects of improvement in this embodiment, will be described.

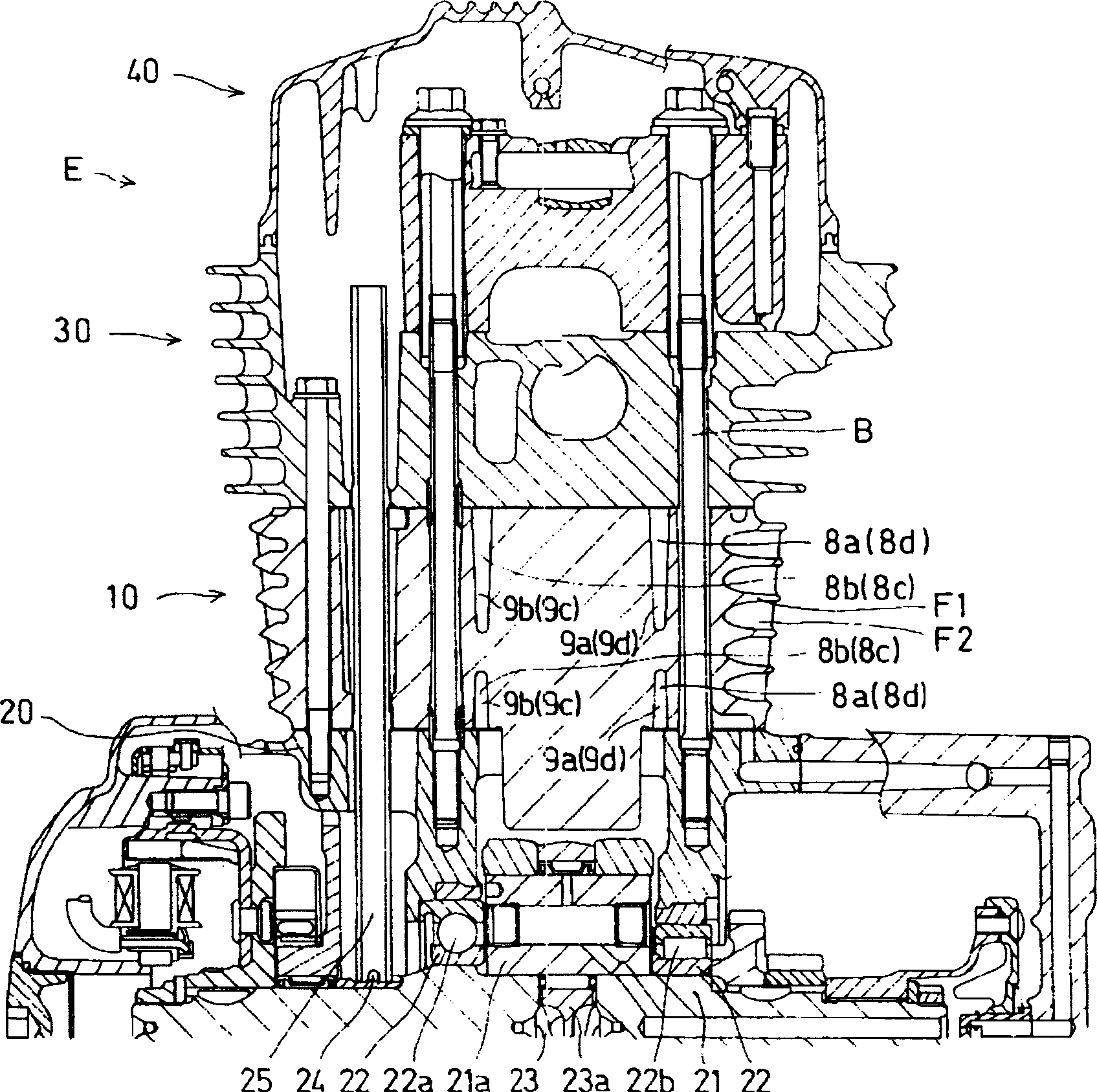

[0027] exist figure 1 In , the structure of the cylinder block 10 and its vicinity in the internal combustion engine E is shown.

[0028] figure 1 The lower part of the cylinder block part 10 shown in is fastened to the crankcase part 20 , while the upper part thereof is fastened to the cylinder head part 30 . Finally, the crankcase portion 20 , the cylinder block portion 10 and the cylinder head 30 are fastened to each other by stud bolts B .

[0029] In the crankcase part 20, a crankshaft 21 of which part shown is rotatably supported by a bearing 22, figure 1 The bearing on the left side is a ball bearing 22a, and the bearing 22 on the right side is a roller bearing 22b, and the state of use of these two bearings is pa...

Embodiment 2

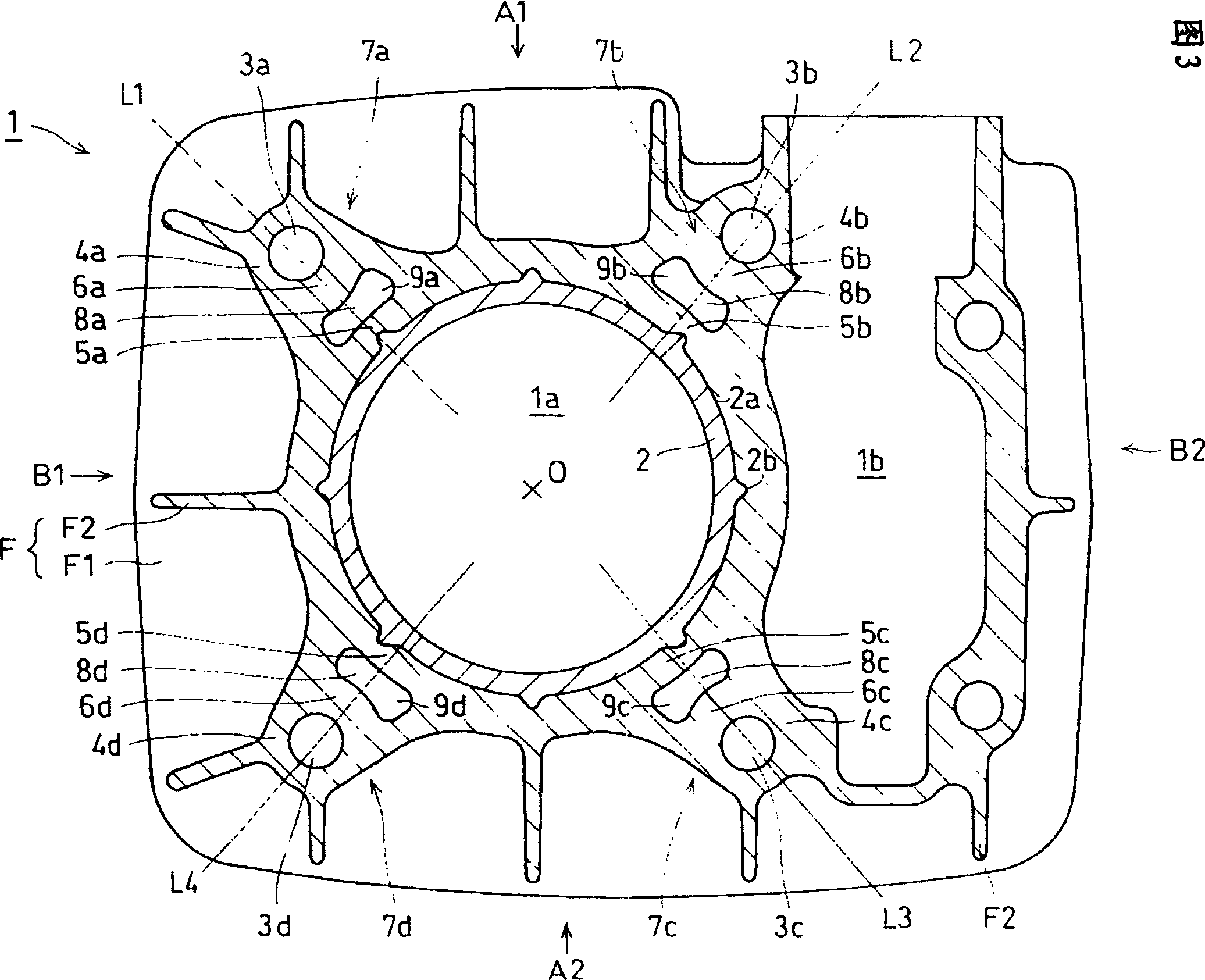

[0047] Embodiment 2 differs from Embodiment 1 in the weight-reducing structure of the aluminum alloy casting part cast into the cylinder block 1 in which the Fe-made cylinder liner 2 is casted, but there are substantially no differences in other structural parts. Centering on the structure of the aluminum alloy casting part weight-reducing holes 8a-8d in the cylinder block 1 in which the Fe-made cylinder liner 2 is cast, the Figure 4 The above-mentioned Embodiment 2 will be described. The same reference numerals are used for structural parts that are substantially the same as those in Embodiment 1. FIG.

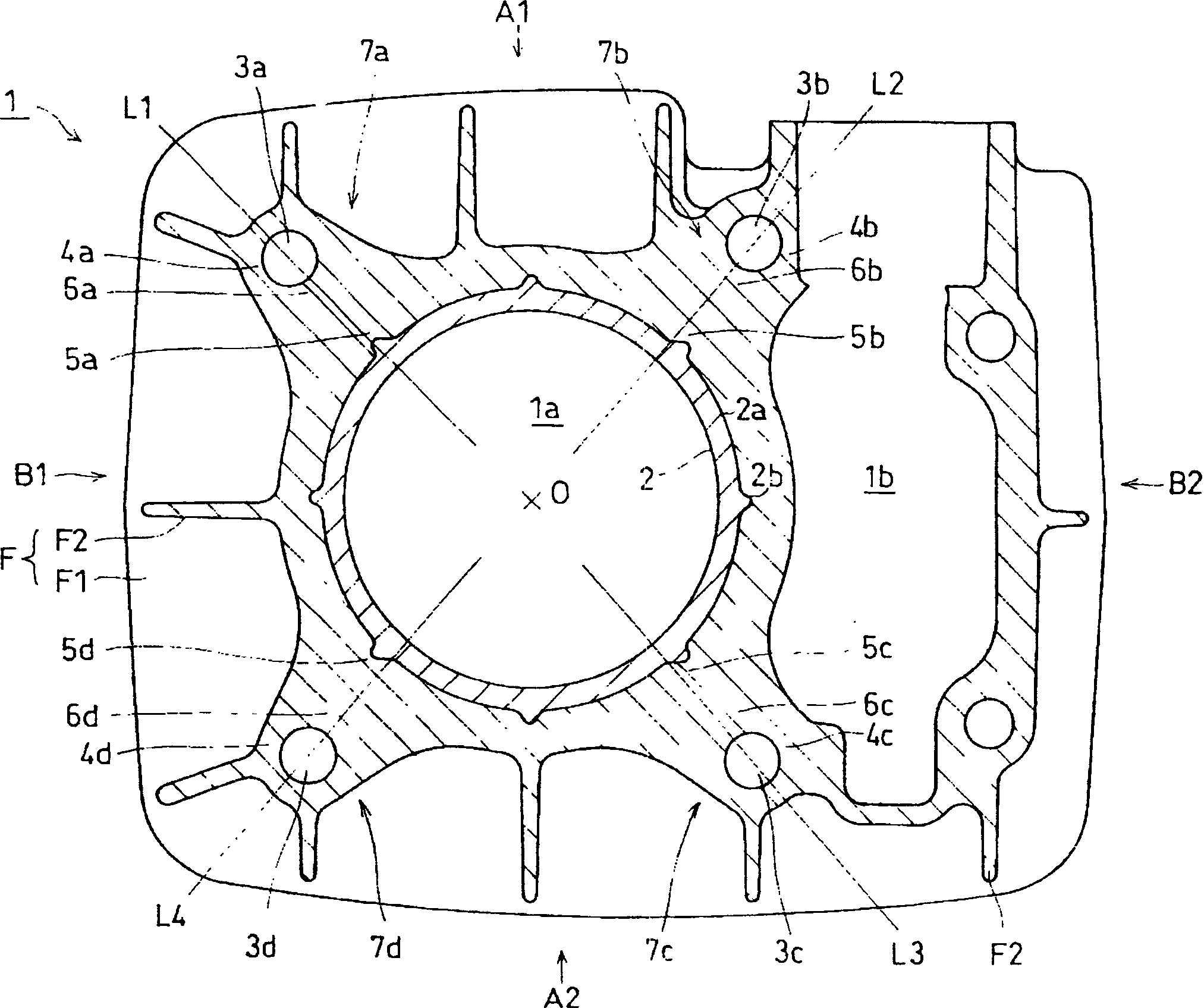

[0048] In this Example 2, figure 2 The weight-reducing holes 8a-8d for uniformizing the wall thickness in the cylinder block 1 before the modification shown above, the wide and thick-walled casting forming parts 7a-7d in the above-mentioned four lines L1-L4, that is, more specifically, the cylinder liner 2 The aluminum alloy cast parts 5a-5d near the outer peripheral part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com