Garbage treating plant with low energy consumption and treating method thereof

A technology of waste treatment equipment and low energy consumption, applied in medical waste treatment equipment and in the field of waste treatment that does not pollute the environment, can solve the problems of surrounding environmental pollution, low furnace temperature, secondary environmental pollution, etc., to achieve low operating costs, gas Low volume and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

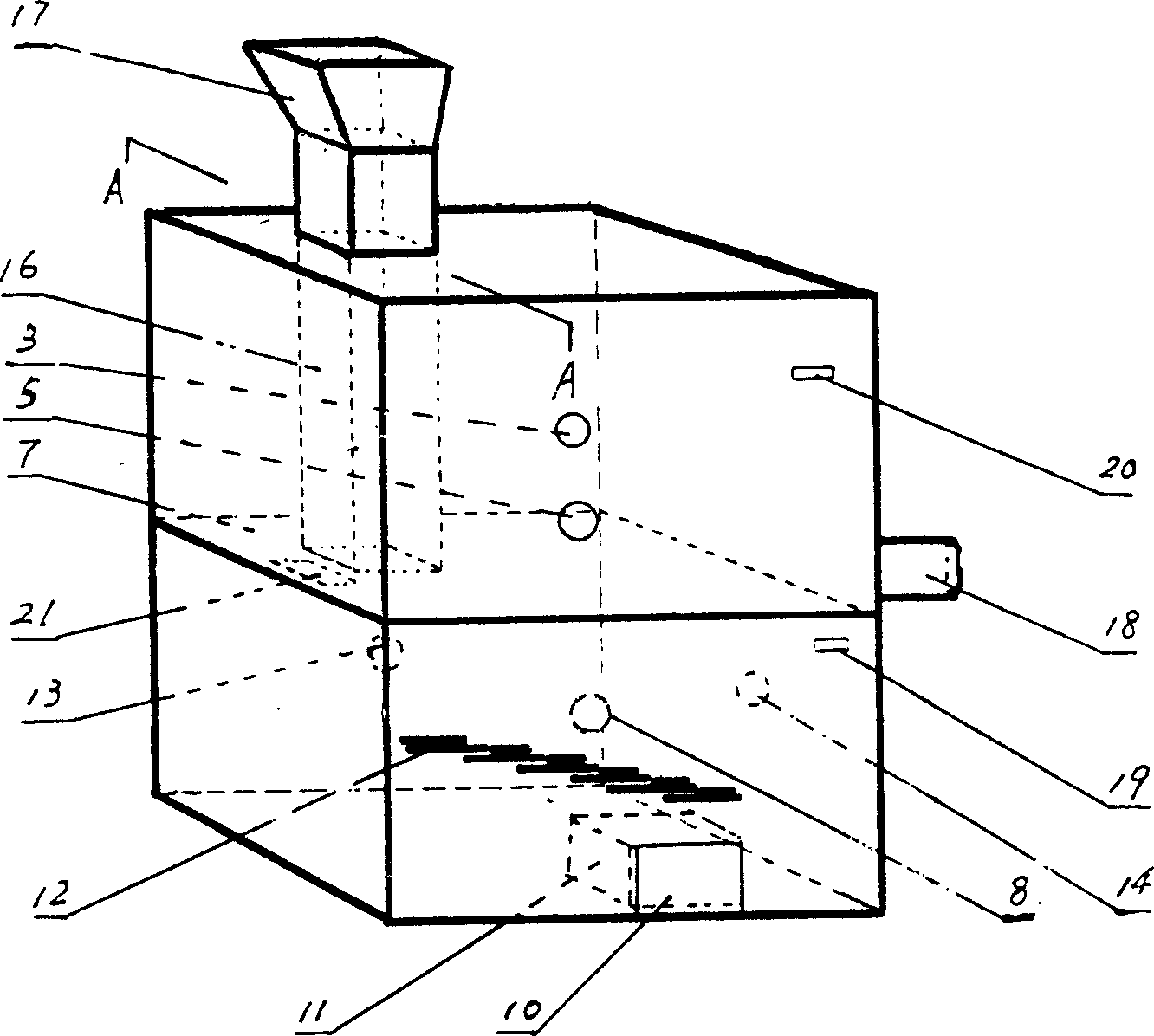

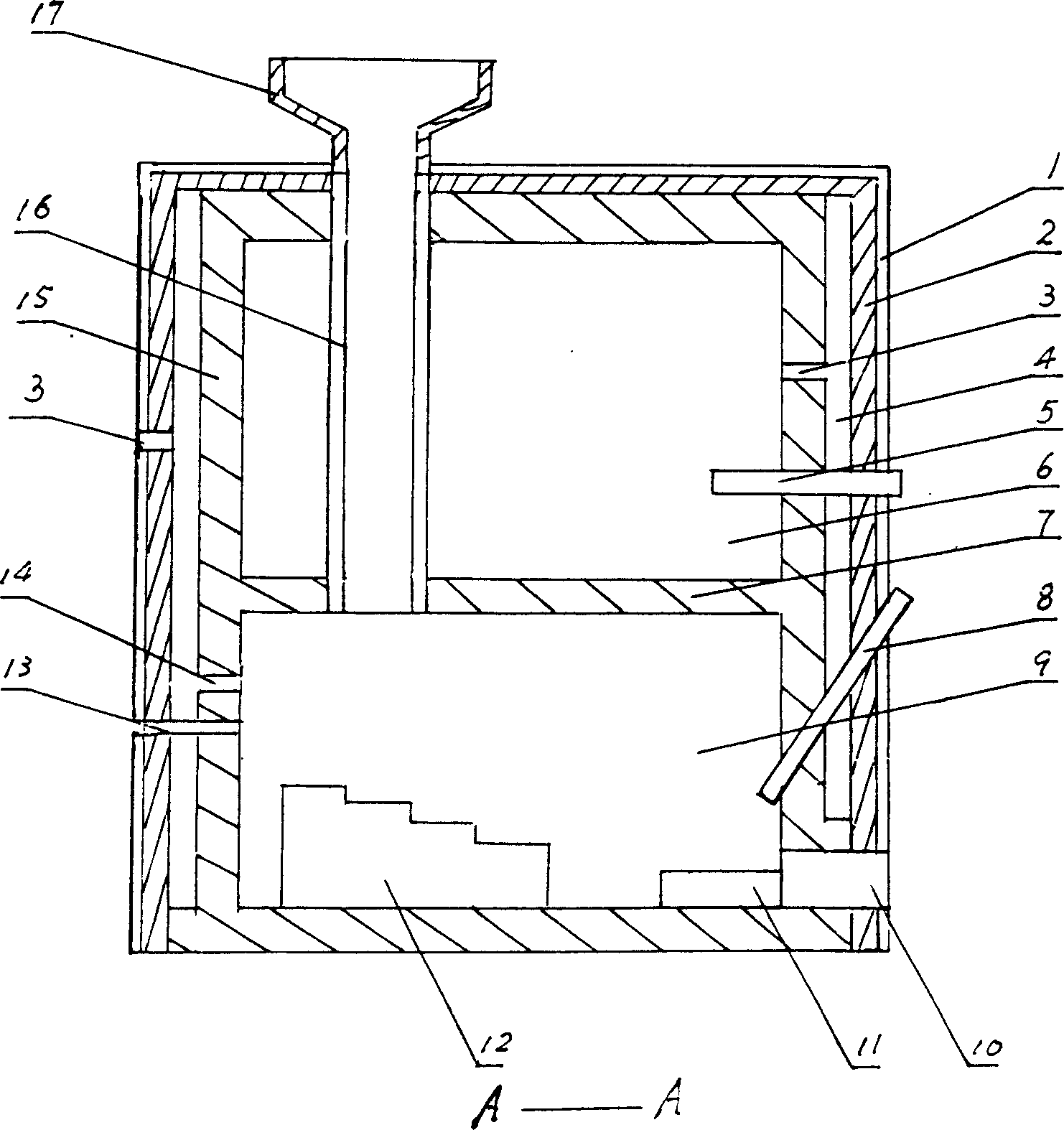

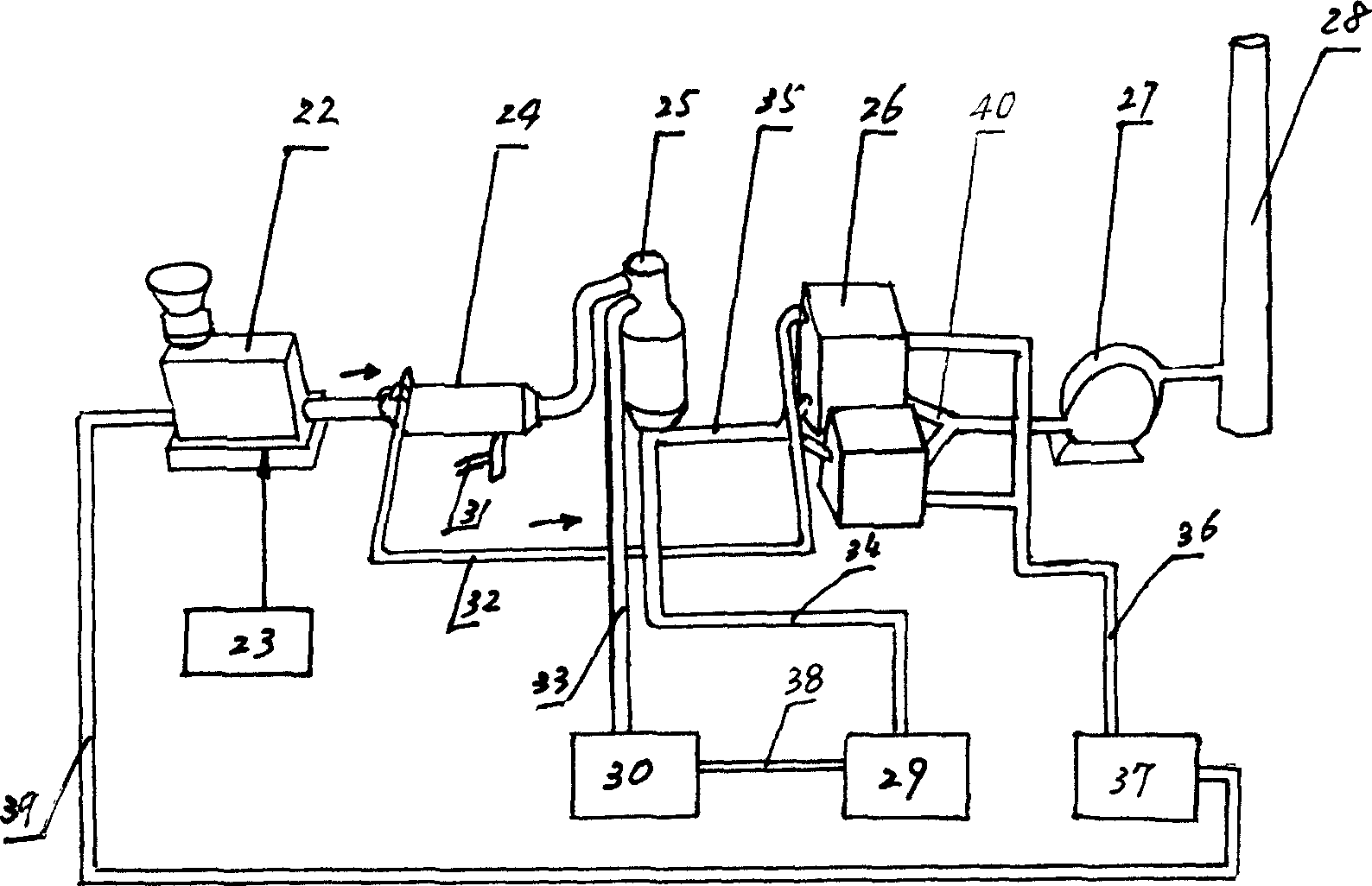

[0016]A low-energy consumption and non-environmental-pollution garbage treatment equipment, comprising a low-energy plasma garbage incinerator 22, a plasma arc power supply, a working medium gas supply system, Cathodic protection gas supply system, water cooling system to prevent overheating of the cathode and anode of the plasma generator, gas system and air supply system for respectively providing gas and combustion-supporting air to the incinerator 22, connected to the exhaust outlet 18 of the incinerator 22 for extraction The tail gas treatment system is composed of a harmless treatment of the tail gas; it consists of the furnace shell 1, the insulation layer 2 inside the shell, the air interlayer 4 connected to the air inlet 3 and 14 on the inside of the insulation layer 2, and the combustion chamber constructed of high-temperature refractory materials In the incinerator 22, the combustion chamber is divided into two upper and lower combustion chambers 6 and 9 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com