Iron-making system of hydrogen-rich and carbon-rich circulating blast furnace

A carbon cycle and hydrogen-rich technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of reduced CO2 emissions per ton of iron, reduced demand for fossil fuels, and insufficient top gas circulation of all-oxygen blast furnaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

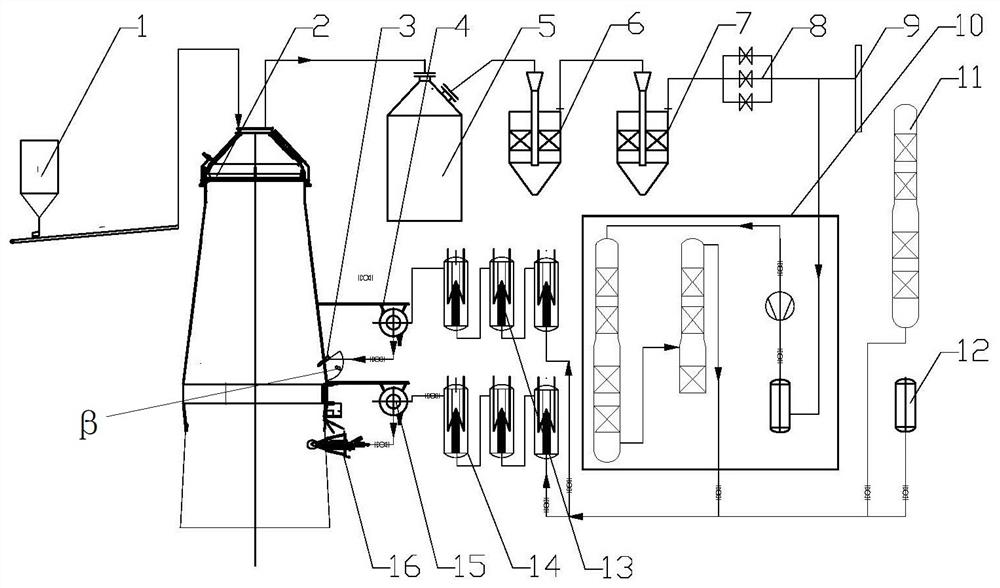

[0021] refer to figure 1 , the production system of the hydrogen-rich carbon cycle blast furnace is specifically:

[0022] 1) The process system of the hydrogen-rich carbon cycle blast furnace ironmaking includes the hydrogen-rich carbon cycle blast furnace and top gas cycle decarburization and heating injection system. On the hearth of the hydrogen-rich carbon cycle blast furnace, there are oxygen tuyeres and gas injection ports. The composite tuyere device is equipped with a shaft heating gas inlet in the middle and lower part of the blast furnace shaft, the injection gas pressure is 0.35MPa (gauge pressure), and the temperature is 850~950°C.

[0023] The composite tuyere device is used to blow in pure oxygen and tuyere heating gas, and the tuyere heating gas and furnace shaft heating gas inlets are used to blow in high-temperature upgrading gas produced by electric heating after CO2 is circulated and removed from the top of the furnace. The temperature at which the high-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com