Energy-saving type shuttle type kiln

A shuttle kiln and burner technology, which is applied in the field of shuttle kiln, can solve the problems of product color difference, smoke outlet deflection, etc., and achieve the effects of reducing product color difference, improving thermal efficiency, and improving temperature distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

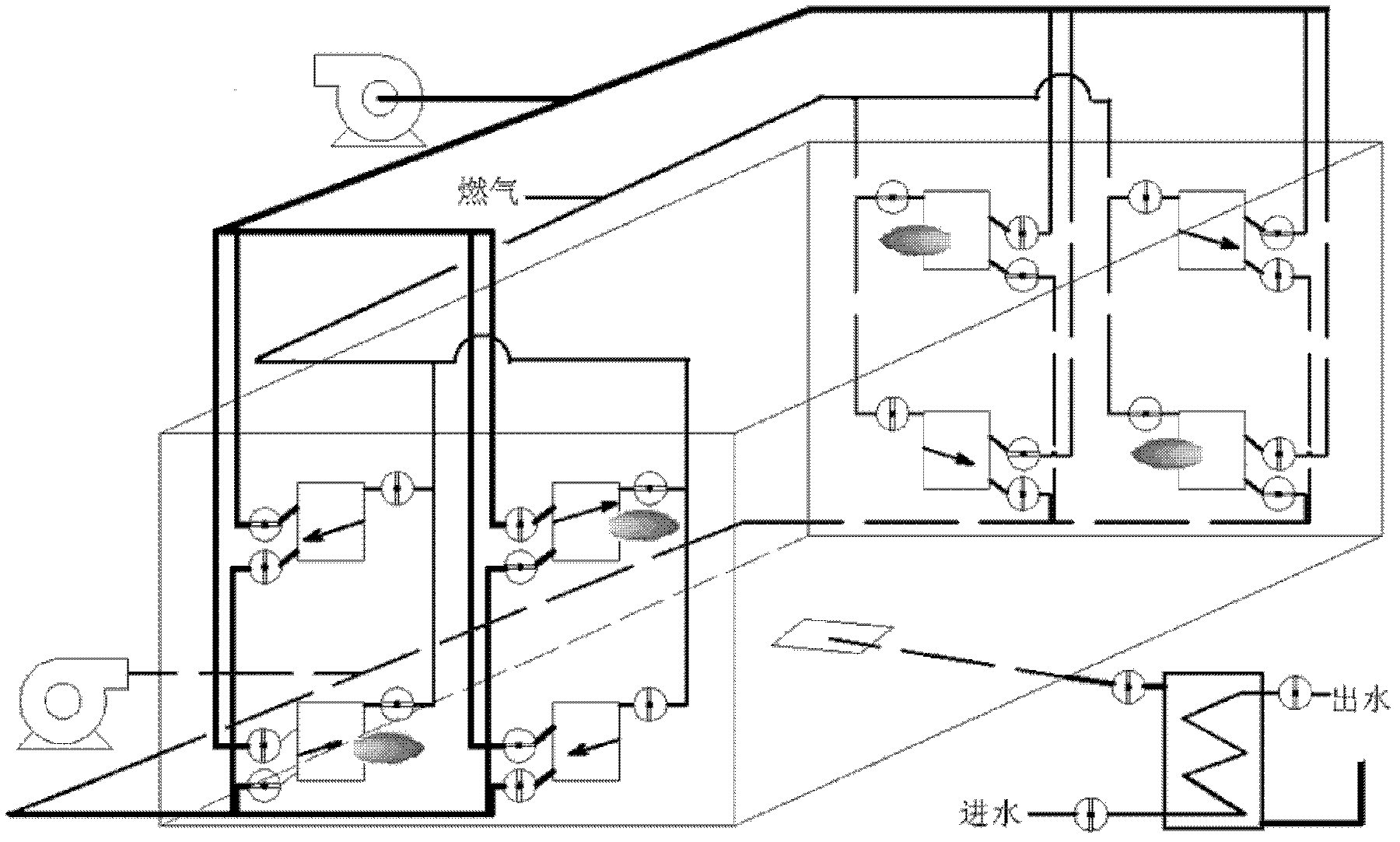

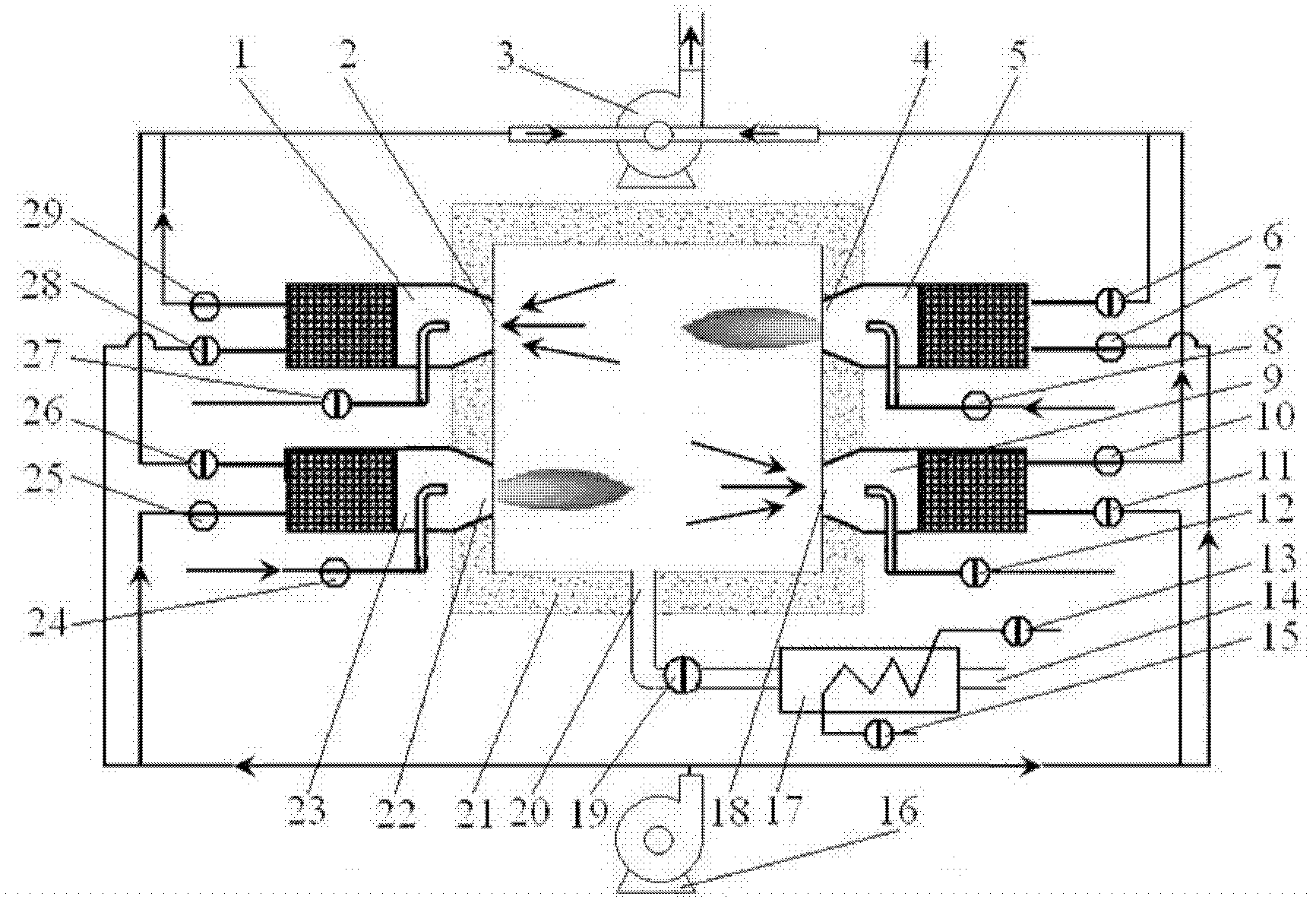

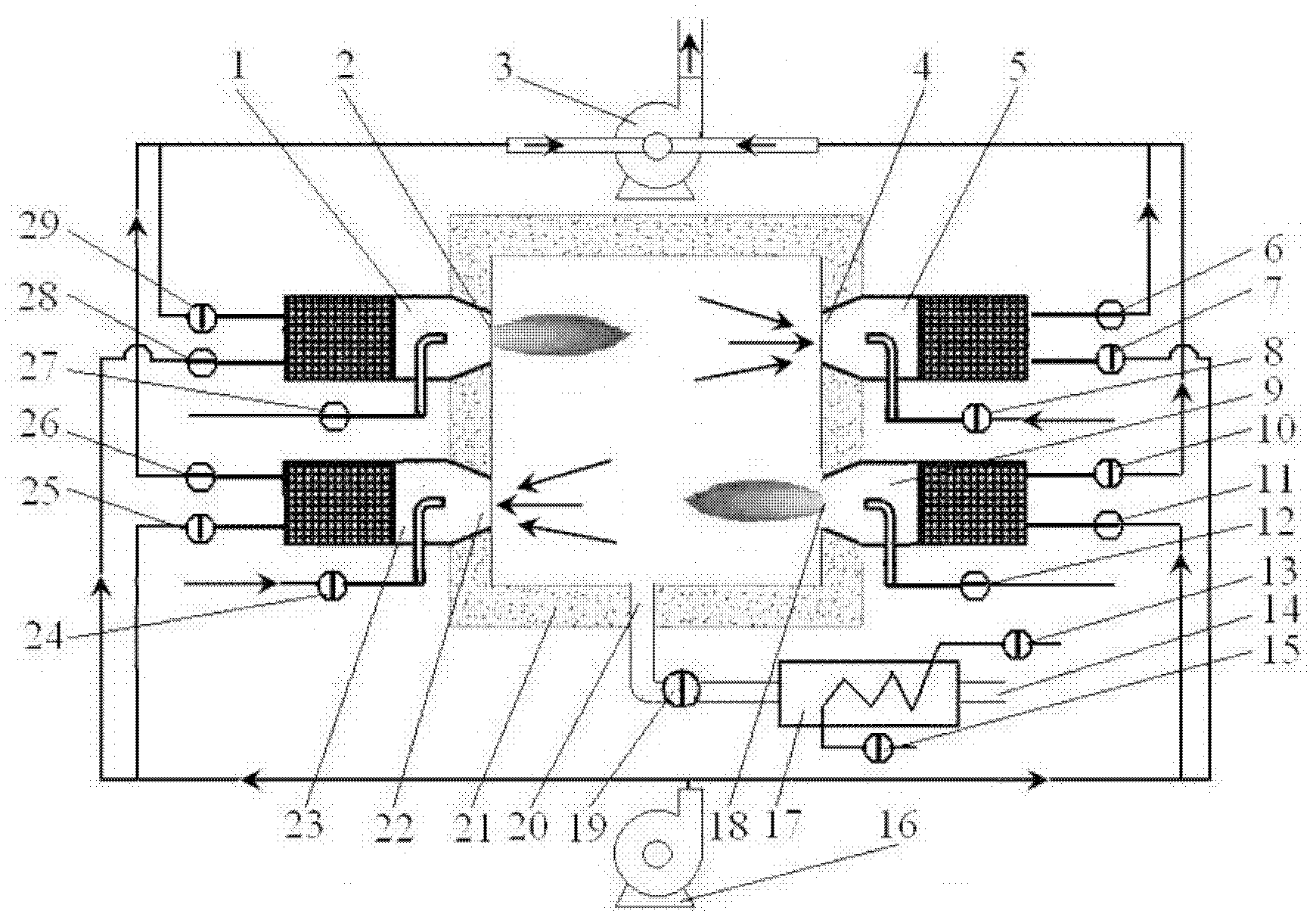

[0027] The shuttle kiln in this embodiment includes at least one fire channel, and the longer the kiln body, the more the number of fire channels. At least one pair of burners is installed on each fire channel, and two burners in each pair of burners are respectively installed on two side walls of the fire channel. In this embodiment, each fire path is preferably two pairs of burners, and two adjacent fire paths are optional. For details, see figure 1 shown. figure 1 When two pairs of burners are installed on each fire path, the combustion and smoke exhaust on two adjacent fire paths are in a cross state, that is, one of the fire paths is in a state of figure 2 In the running state shown, the adjacent fire path is in image 3 The operating status shown. And when there are multiple fire channels, in order to avoid large fluctuatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com