Dry quenching gas regulation method of coal internal heat low temperature pyrolysis

A CDQ and hot gas technology, which is applied in the field of CDQ gas control in coal internal thermal low-temperature carbonization, can solve the problems of reducing the calorific value of gas, the failure of crushed coal to be put into the furnace for carbonization, and the lack of high value-added utilization of gas, etc. To achieve the effect of reducing hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: the application of annual processing 600,000 tons semi-coke production plant

[0055] (1) Basic information:

[0056] The semi-coke production plant with an annual processing capacity of 600,000 tons adopts a vertical square furnace as the basic production equipment, air-assisted combustion, and a coal-to-coke ratio of 1.65:1. The tar yield is about 8%, and the combustion and circulation gas volume is 549Nm 3 / t 兰炭 , the amount of combustion air into the furnace is 190m 3 / t 兰炭 , the amount of gas used for drying is 100Nm 3 / t 兰炭 , the remaining gas volume per ton of coal is 460Nm 3 / t 兰炭 About (Shenmu dry-based raw coal as the benchmark), gas calorific value 6771-7106kJ / Nm 3 . The reference gas composition is as follows:

[0057] h 2 : 16.2%, CO: 14.49%, CO 2 : 7.41%, CH 4 : 5.68%, Nitrogen: 50.10%. Calorific value: 7029kJ / m 3 .

[0058] (2) Application method

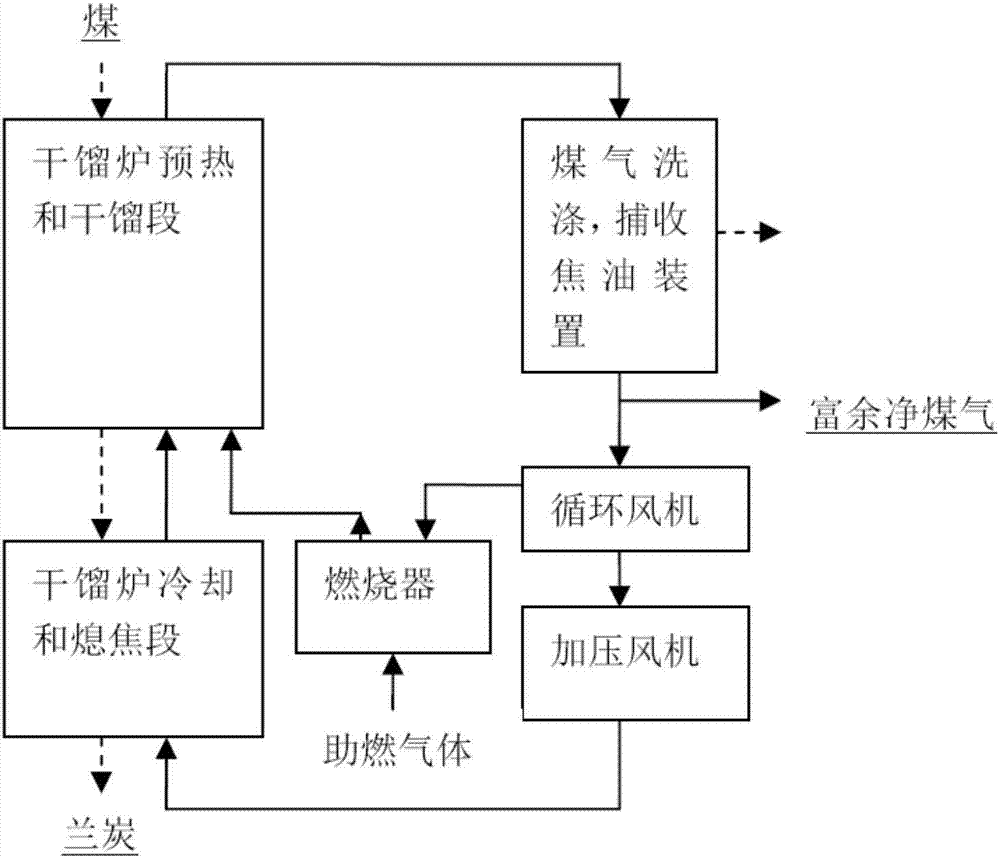

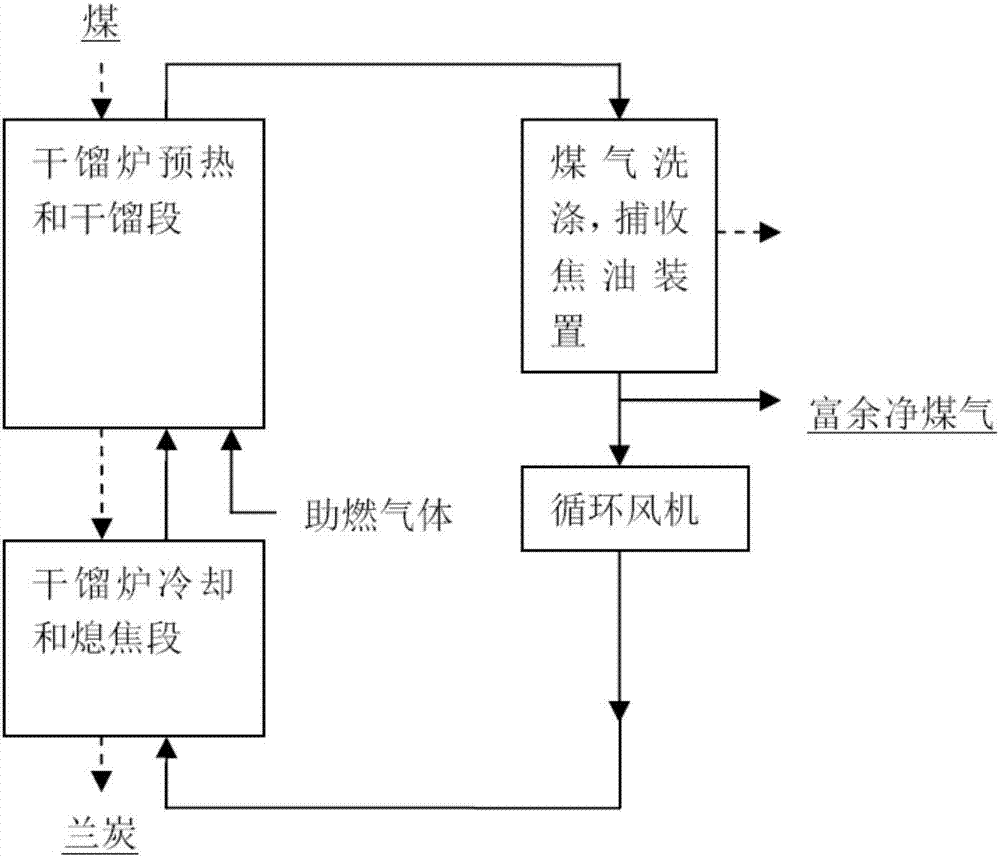

[0059] Applied as figure 2 shown. Renovate the original retort furnace, in...

Embodiment 2

[0064] Embodiment 2: the application of the semi-coke production plant with an annual output of 600,000 tons

[0065] (1) Basic information

[0066] The semi-coke production plant with an annual processing capacity of 600,000 tons uses a vertical square furnace as the basic production equipment, with oxygen-enriched air for combustion, an oxygen-enriched ratio of 80%, a coal-to-coke ratio of 1.65:1, and a tar yield of about 8%. Combustion and circulating gas volume 619m 3 / t 兰炭 , the amount of oxygen-enriched air into the furnace is 100m 3 / t 兰炭 , the amount of gas used for drying is 100Nm 3 / t 兰炭 , the remaining gas volume per ton of coal is 260Nm 3 / t 兰炭 Around, gas calorific value 13102kJ / Nm 3 . The reference gas composition is as follows:

[0067] h 2 : 35.05%, CO 23.04%, CO 2 : 12.06%, CH 4 : 12.55%, Nitrogen: 9.85%. Calorific value of gas 13102kJ / m 3 .

[0068] (2) Application method

[0069] The application method is basically the same as Example 1. Re...

Embodiment 3

[0072] Embodiment 3: the application of the semi-coke production plant with an annual output of 1.2 million tons

[0073] (1) Basic information

[0074] The vertical square furnace is used as the basic production equipment, and the air with an oxygen-enriched ratio of 30% is used for combustion. It has been modified and installed with a CDQ device. The coal-to-coke ratio is 1.67:1, the tar yield is about 7.6%, and the moisture content of semi-coke is 1.5~ 2.0%, no drying process. Combustion and circulating gas volume 861Nm 3 / t 兰炭 , the amount of combustion air into the furnace is 136m 3 / t 兰炭 , surplus gas volume 532m 3 / t 兰炭 , gas calorific value 9231.0-9342.8kJ / Nm 3 .

[0075] (2) Application method

[0076] The combustion gas fans, pipelines and regulating valves were stopped, the burners were canceled, and the fire path (flower wall) was remodeled to use small-hole ventilation bricks. Appropriately reduce the amount of combustion air. The specific application met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com