Composite staged gasification reaction device and method thereof

A gasification reaction and composite technology, which is used in the manufacture of combustible gas and the petroleum industry, can solve the problems of narrow selection of raw materials, low carbon conversion rate and gasification intensity, complex by-products, etc., to achieve uniform flame temperature distribution and conversion. The effect of improving the rate and simplifying the target product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

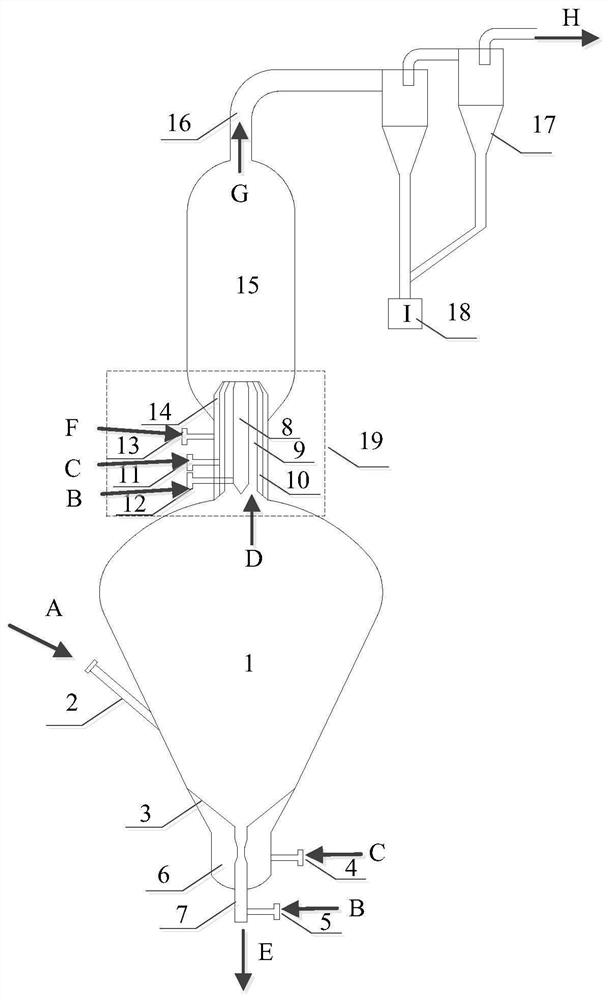

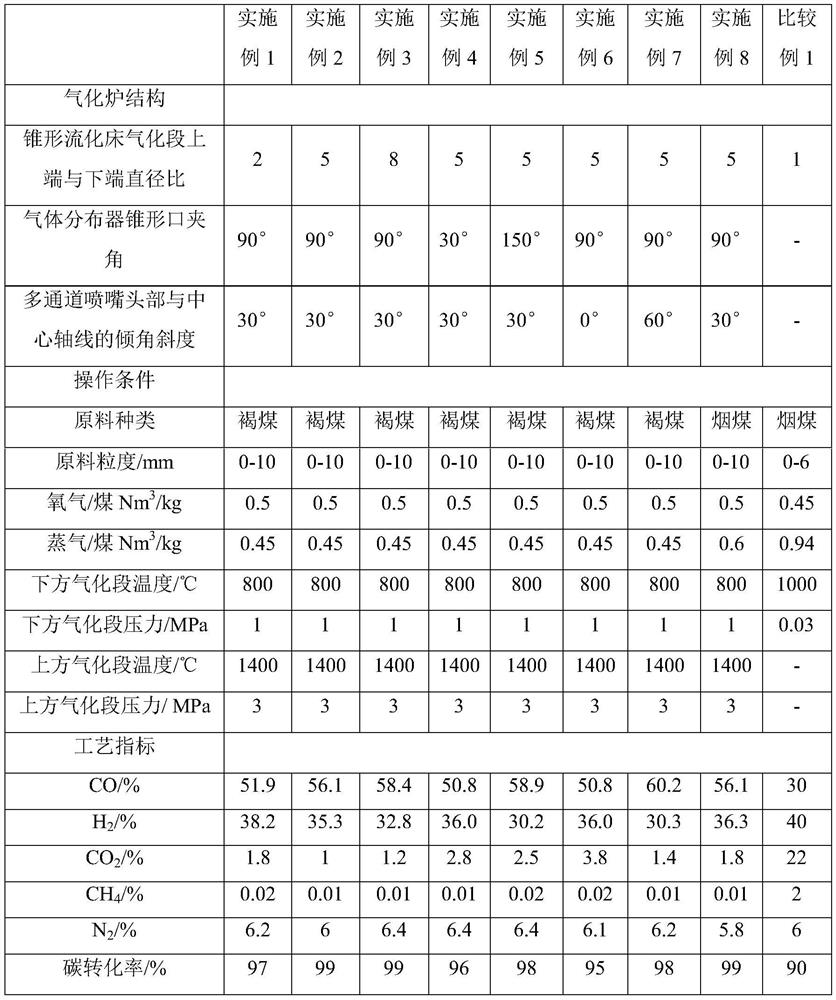

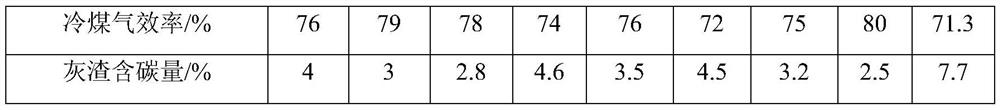

[0034] A composite staged gasification reaction device, the inner diameter of the lower end of the conical fluidized bed gasification section is 0.5m, the maximum inner diameter of the upper end is 1m, and the height is 5m. The angle between the conical mouth of the gas distributor is 90°. There are 20 circles of air holes, the opening rate is 2%, the air holes are evenly arranged along the circumference, the diameter of each circle of air holes increases radially along the distributor, the air holes near the center of the slag discharge pipe are the smallest, the smallest air hole is 1mm, the largest air hole is 10mm, the multi-channel nozzle The heads of the center nozzle, the inner ring nozzle and the outer ring nozzle all adopt a tapered structure, and the inclination angle with the central axis is 30°.

[0035] Through the feeder, the 0-10mm Inner Mongolia lignite enters the conical fluidized bed gasification section through the raw material inlet pipe, and when the temper...

Embodiment 2

[0037] A composite staged gasification reaction device, the inner diameter of the lower end of the conical fluidized bed gasification section is 0.5m, the maximum inner diameter of the upper end is 2.5m, and the height is 5m. The angle between the conical mouth of the gas distributor is 90°. There are 20 circles of air holes, the opening rate is 2%, the air holes are evenly arranged along the circumference, the diameter of each circle of air holes increases radially along the distributor, the air holes near the center of the slag discharge pipe are the smallest, the smallest air hole is 1mm, the largest air hole is 10mm, multi-channel nozzle The heads of the central nozzle, the inner ring nozzle and the outer ring nozzle all adopt a tapered structure, and the inclination angle with the central axis is 30°.

[0038] Through the feeder, the 0-10mm Inner Mongolia lignite enters the conical fluidized bed gasification section through the raw material inlet pipe, and when the tempera...

Embodiment 3

[0040] A composite staged gasification reaction device, the inner diameter of the lower end of the conical fluidized bed gasification section is 0.5m, the maximum inner diameter of the upper end is 4m, and the height is 5m. The angle between the conical mouth of the gas distributor is 90°. There are 20 circles of air holes, the opening rate is 2%, the air holes are evenly arranged along the circumference, the diameter of each circle of air holes increases radially along the distributor, the air holes near the center of the slag discharge pipe are the smallest, the smallest air hole is 1mm, the largest air hole is 10mm, the multi-channel nozzle The heads of the center nozzle, the inner ring nozzle and the outer ring nozzle all adopt a tapered structure, and the inclination angle with the central axis is 30°.

[0041] Through the feeder, the 0-10mm Inner Mongolia lignite enters the conical fluidized bed gasification section through the raw material inlet pipe, and when the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com