Steel enterprise associated energy combined cycle power generation system and method

A combined cycle power generation and associated energy technology, applied in the energy industry, improving energy efficiency, machines/engines, etc., can solve problems such as insignificant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

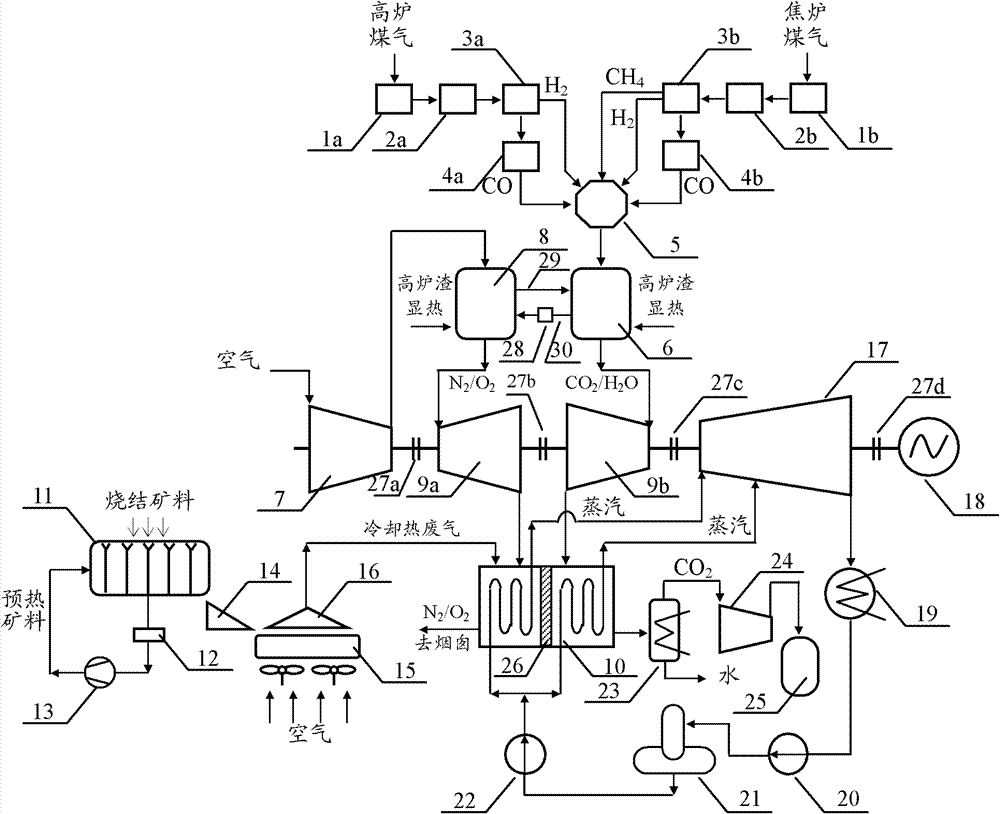

[0046] Such as figure 1 As shown, the present invention is based on chemical looping combustion associated energy combined cycle power generation system for iron and steel enterprises, including fuel gas preparation subsystem, chemical looping combustion subsystem, sintering flue gas treatment subsystem and hot gas-steam combined cycle power generation subsystem.

[0047] The fuel gas preparation subsystem includes a fuel gas processing device for processing blast furnace gas, a fuel gas processing device for processing coke oven gas, and a fuel gas mixer 5 .

[0048] The fuel gas treatment device for processing blast furnace gas includes blast furnace gas compression equipment 1a, blast furnace gas purification equipment 2a, blast furnace gas pressure swing adsorption equipment 3a and blast furnace gas negative pressure swing adsorption equipment 4a connected in sequence; the specific connection method It is: the outlet of the blast furnace gas compression equipment 1a commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com