A kind of injection pre-combustion flameless burner

A flameless combustion and pre-combustion chamber technology, applied in the direction of gas fuel burners, burners, burners burning powder fuel, etc., can solve problems such as uneven temperature distribution, high nitrogen oxide emissions, and insufficient combustion. Achieve the effects of overcoming uneven temperature distribution, improving combustion efficiency, and speeding up the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

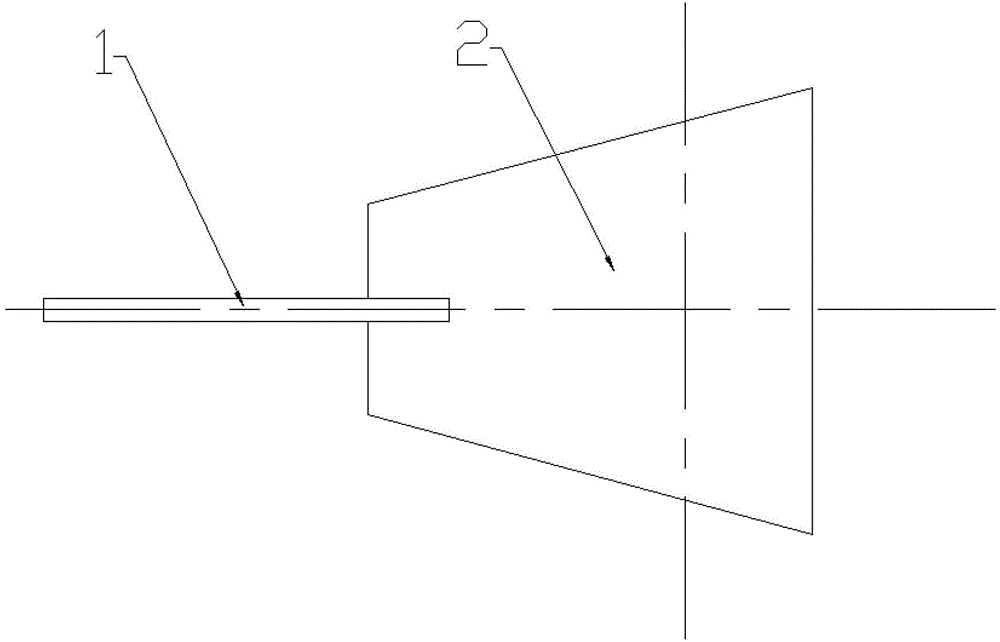

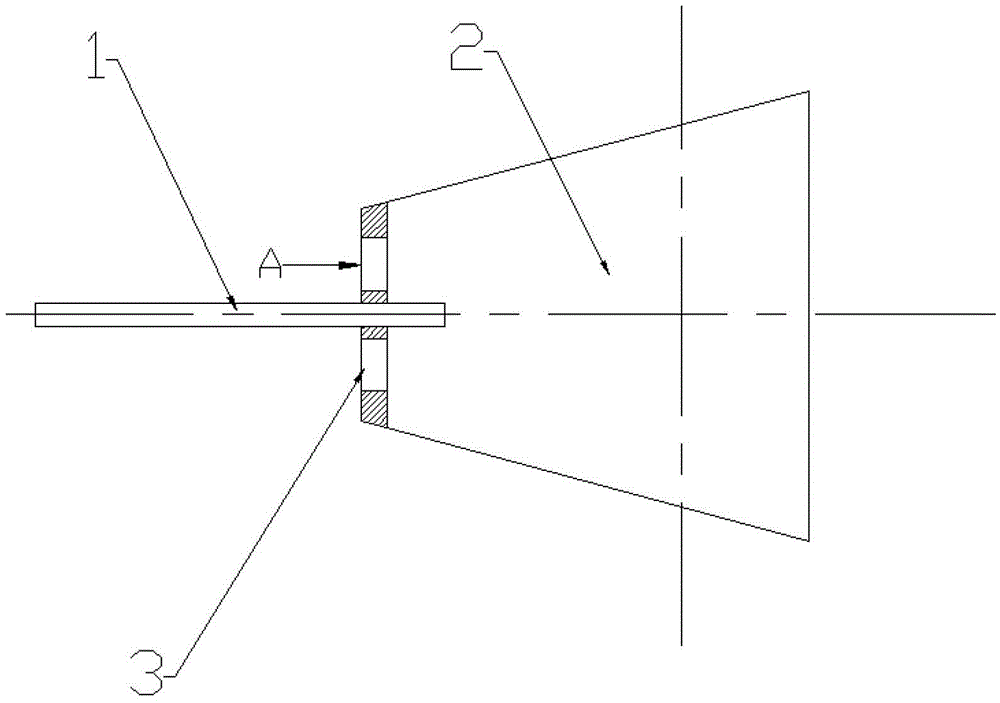

[0023] In this embodiment, it consists of a nozzle 1 and a pre-chamber 2; the front end of the pre-chamber 2 washes out 8 grooves 3 with b=0° (see figure 2 , 4, 5, that is, the groove 3 is a straight groove); the nozzle 1 goes directly into the pre-combustion chamber 2; the end of the pre-combustion chamber 2 is directly connected to the furnace.

[0024] The working principle of the embodiment of the present invention is as follows (the fuel used in the implementation of the embodiment of the present invention is solid or gaseous fuel):

[0025] In the initial stage, the fuel supply device passes N 2 The fuel is sprayed into the pre-chamber 2 through the nozzle 1. At the same time, due to the turbulent diffusion of the jet, the entrained hot air enters into the pre-chamber 2 through the groove 3, and the two interact in the pre-chamber 2. Mixing, because the temperature of the hot air is enough to reach the ignition point of the fuel, so that the two can be mixed and burned...

Embodiment 2

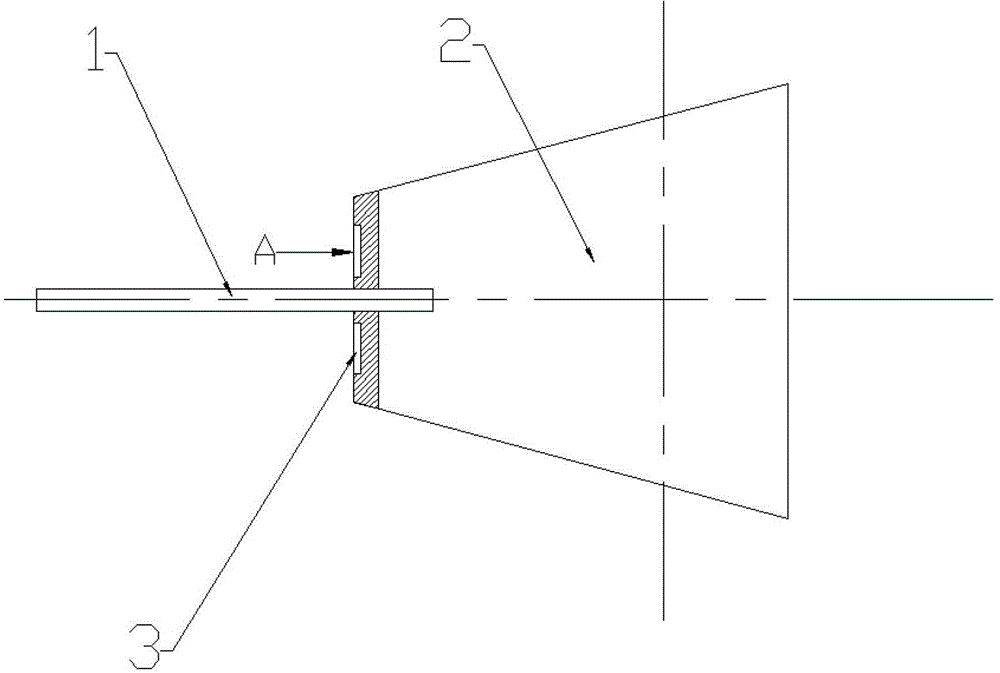

[0027] In this embodiment, it consists of a nozzle 1 and a pre-chamber 2; the front end of the pre-chamber 2 washes out 8 grooves 3 with b=30° (see image 3 , 4, 6, 7, that is, the groove 3 is a chute), the groove 3 is evenly distributed in the right or left direction; the nozzle 1 goes directly into the pre-combustion chamber 2; the end of the pre-combustion chamber 2 is directly connected to the furnace.

[0028] The working principle of the embodiment of the present invention is as follows (the fuel used in the implementation of the embodiment of the present invention is solid or gaseous fuel):

[0029] In the initial stage, the fuel supply device passes N 2 The fuel is sprayed into the pre-chamber 2 through the nozzle 1. At the same time, due to the turbulent diffusion of the jet, the entrained hot air enters into the pre-chamber 2 through the groove 3, and the two interact in the pre-chamber 2. Mixing, because the temperature of the hot air is enough to reach the ignitio...

Embodiment 3

[0031] In this embodiment, it consists of a nozzle 1 and a pre-chamber 2; the front end of the pre-chamber 2 washes out 8 grooves 3 with b=70° (refer to b=30°, that is, the groove 3 is still a chute), and the groove 3 Right-handed or left-handed evenly distributed; Nozzle 1 goes deep into the pre-chamber 2; The end of the pre-chamber 2 is directly connected to the furnace.

[0032] The working principle of the embodiment of the present invention is as follows (the fuel used in the implementation of the embodiment of the present invention is solid or gaseous fuel):

[0033] In the initial stage, the fuel supply device passes N 2 The fuel is sprayed into the pre-chamber 2 through the nozzle 1. At the same time, due to the turbulent diffusion of the jet, the entrained hot air enters into the pre-chamber 2 through the groove 3, and the two interact in the pre-chamber 2. Mixing, because the temperature of the hot air is enough to reach the ignition point of the fuel, so that the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com