Plastic extruder facilitating filtering of impurities

A plastic extruder and filter mechanism technology, applied in the field of plastic extruders, can solve the problems of easy filter blockage, inconvenient cleaning inside the blockage, unstable flow rate of plastic melt, etc., to achieve convenient replacement and cleaning, and improve the filtering effect , Easy to clean and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

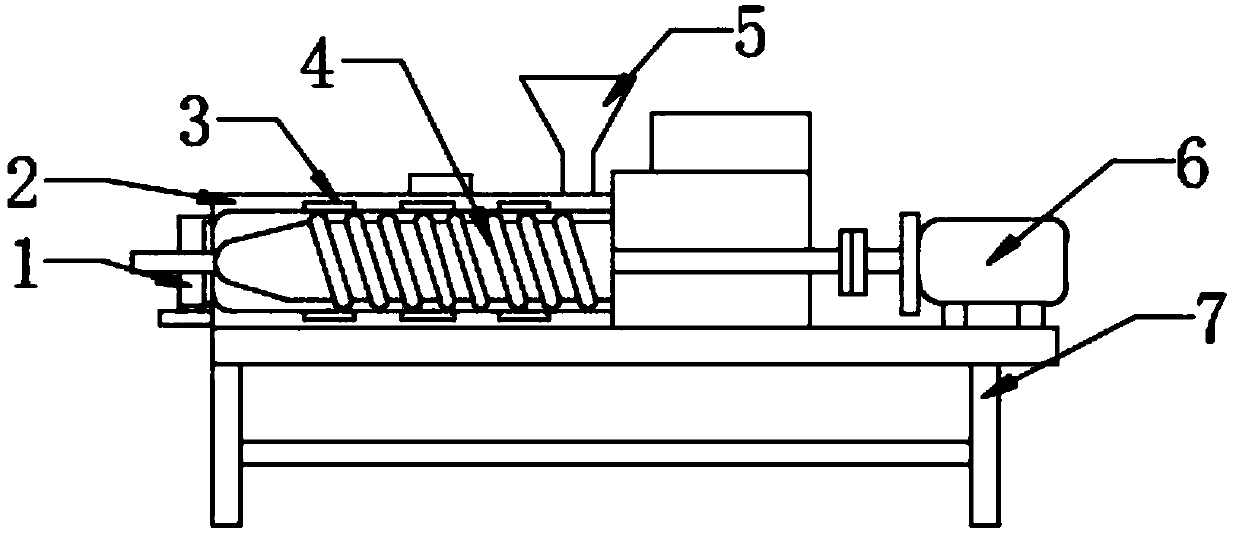

[0019] A plastic extruder that facilitates filtering of impurities such as figure 1 and figure 2 , including machine head filter mechanism 1, machine barrel 2, heater 3, screw rod 4, feeding port 5, motor 6 and fixed frame 7, machine head filter mechanism 1 is arranged on the left end of machine barrel 2, and machine barrel 2 is arranged on the screw 4 annular side, the heater 3 is arranged on the annular side of the screw 4, the screw 4 is arranged on the lower side of the feeding port 5, the motor 6 is arranged on the right side of the upper end surface of the fixed frame 7, and the feeding port 5 is set on the upper side of the barrel 2 annular side .

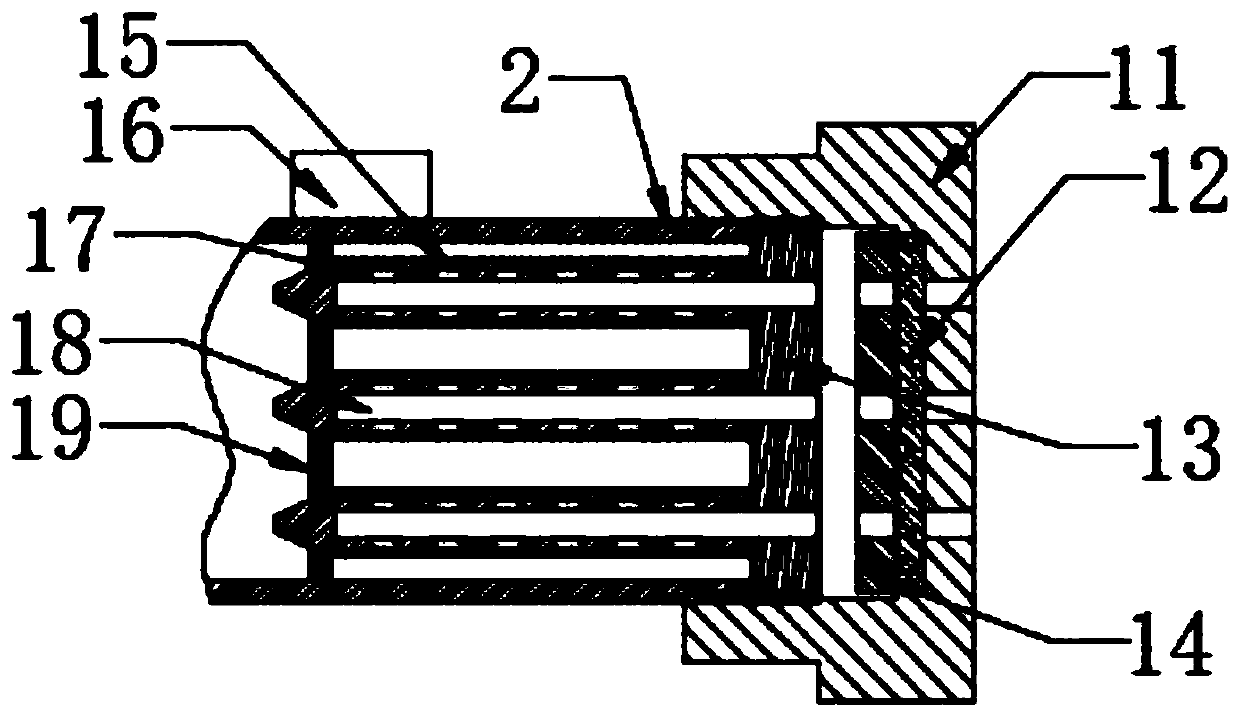

[0020] Machine head filter mechanism 1 includes machine head gland 11, fine filter screen 12, end plate 13, feeding plate 14, filter screen 15, vibration motor 16, filter cartridge 17, injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com