Special sponge grinding material spraying device

A kind of abrasive and sponge technology, applied in the field of surface cleaning equipment, can solve the problems of low work efficiency, not easy to fall, poor fluidity, etc., and achieve the effect of simple structure, no blockage of pipelines, and overcoming shed materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

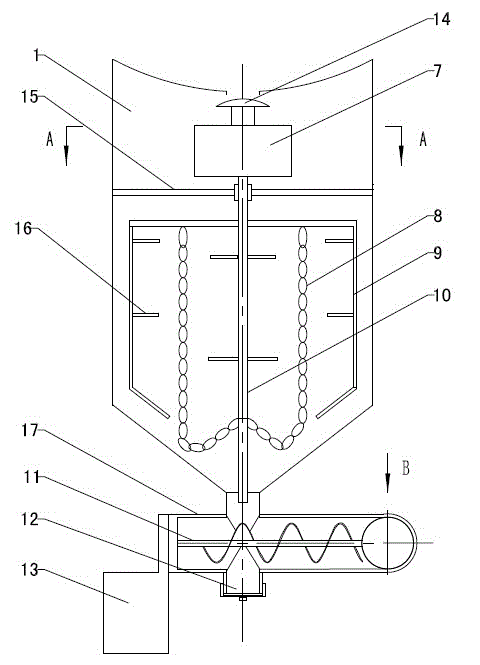

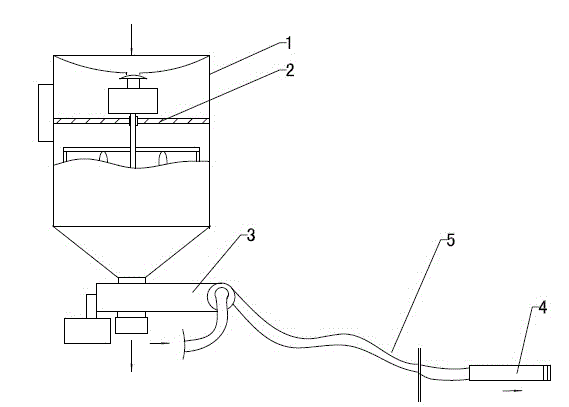

[0027] Refer to attached Figure 1~4 : This kind of sponge abrasive spraying equipment is mainly composed of a material storage pressure tank 1, a stirring device 2, a screw feeding device 3, a nozzle 4 and a compressed air power system 5, and the material storage pressure tank 1 is vertically fixed by a central shaft 10 Install the stirring device 2, the top of the stirring device 2 is provided with an on-off switch 14 that controls the opening and closing of the top feed port of the storage pressure tank 1, and the outlet at the bottom of the storage pressure tank 1 is connected to the feed port of the screw feeding device 3, and the screw feeding device 3 The outlet is connected to the feed hole of the nozzle 4 through a pipeline, and one side of the inlet hole of the nozzle 4 is connected to the compressed air power system 5, and the compressed air is supplied to the nozzle 4 through the pipeline.

[0028] Stirring device 2 is chain type, adopts electric or pneumatic contr...

Embodiment 2

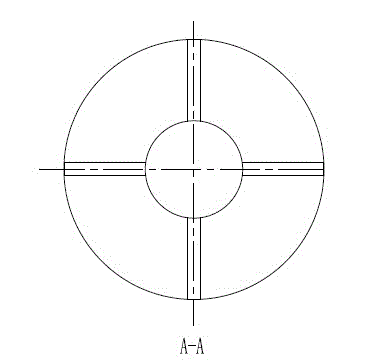

[0037] Refer to attached Figure 5 : Stirring device 2 is a chain type, adopts electric or pneumatic control, and comprises pneumatic stirring motor 7, fixed support 15, stirring support 9 and stirring chain 8 installed on the central shaft 10 successively from top to bottom, and the cross section of fixed support 15 is formed Cross-shaped, the four ends are fixedly connected to the inner wall of the material storage pressure tank 1, the center is connected to the central shaft 10 through bearings, the stirring support 9 is fixedly connected to the central shaft 10, and the stirring support 9 is fixedly connected to the suspended stirring chain 8 .

[0038] The working principle and working process are the same as those in Embodiment 1.

Embodiment 3

[0040] Refer to attached Figure 6 Stirring device 2 includes pneumatic stirring motor 7, fixed support 15, stirring support 9 and stirring teeth 16 installed on the central shaft 10 successively from top to bottom, the cross section of fixed support 15 is cross-shaped, and four ends are fixedly connected to On the inner wall of the material storage pressure tank 1, the center is connected to the central shaft 10 through a bearing, and the stirring support 9 is fixedly connected to the central shaft 10. On the inner wall of the stirring support 9 and on the central shaft 10, a plurality of horizontally arranged stirring teeth 16 are evenly distributed. The stirring teeth 16 on the inner wall of the support 9 and the stirring teeth 16 on the central shaft 10 are arranged at intervals or correspondingly.

[0041] The working principle and working process are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com