Wet dust collector with high-frequency vibration filter screen

A technology of wet dust collector and high-frequency vibration, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, etc. It can solve the problems of easy blockage of wire mesh dust collectors, prevent stagnation, increase pressure loss, and increase contact probability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

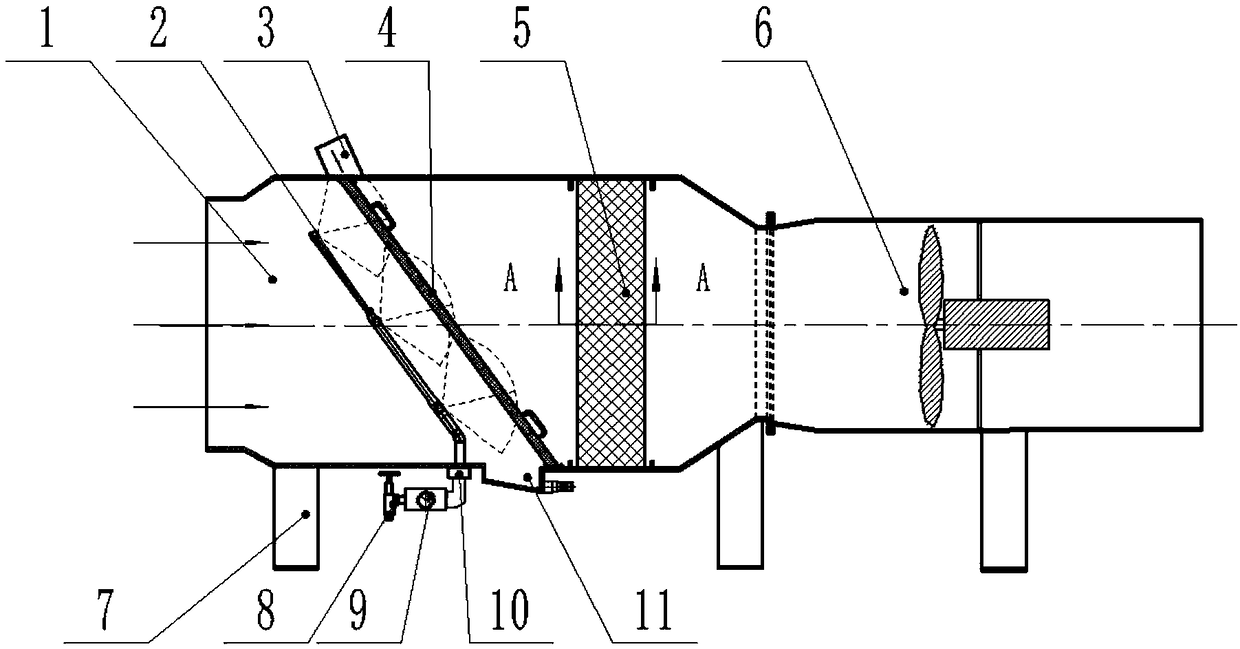

[0019] The present invention proposes a kind of mining nanofiber membrane wet filter deduster, such as figure 1 As shown, it includes dust collector housing 1, spray assembly 2, vibration excitation device 3, filter assembly 4, dehydration assembly 5, axial flow fan 6, support legs 7, pressure regulating valve 8, pressure gauge 9, water pressure uniform distribution chamber 10 and the sink 11.

[0020] Inside the dust collector housing 1, along the direction from the inlet to the outlet, a spray assembly 2, a filter assembly 4, a dehydration assembly 5 and an axial flow fan 6 are sequentially installed. The spray assembly 2 is fixed to the bottom plate of the dust collector housing 1, and is connected to the water pressure uniform distribution chamber 10, the pressure gauge 9 and the pressure regulating valve 8 in sequence through threads. The vibration excitation device 3 is installed on the dust collector housing 1 where the filter assembly 2 is located.

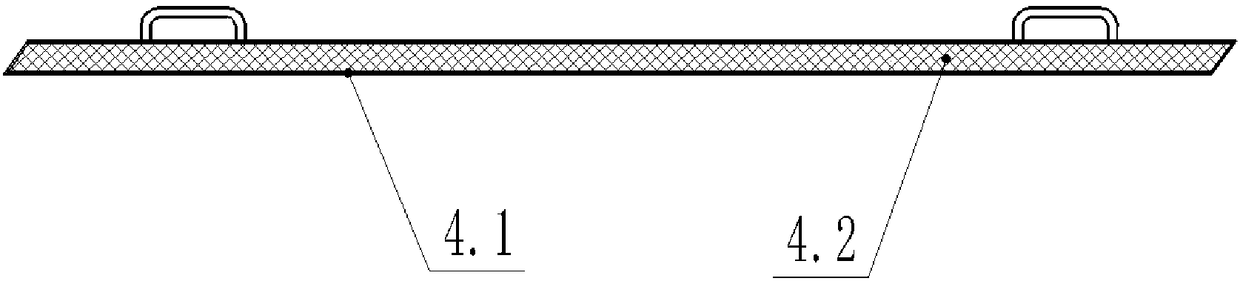

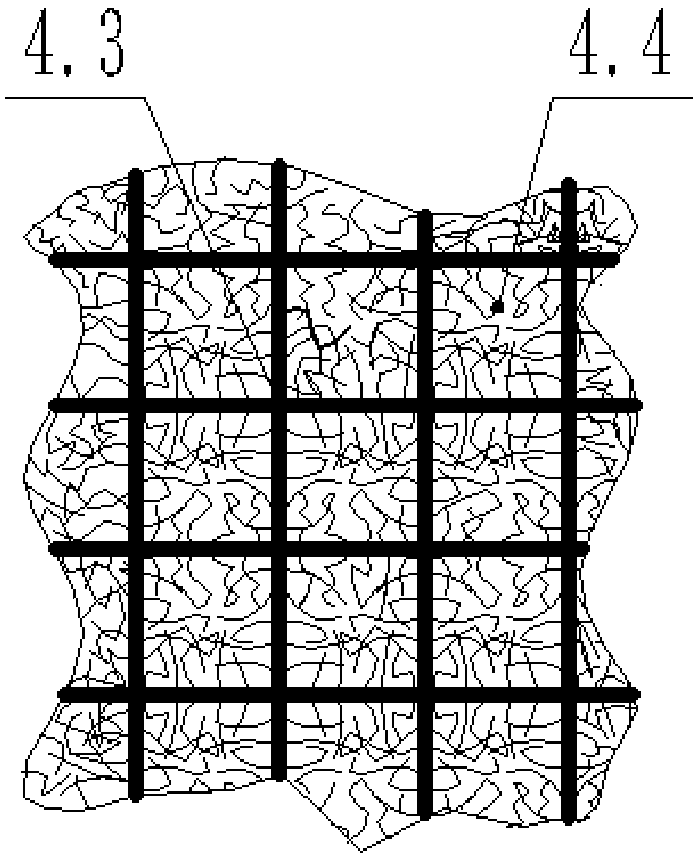

[0021] The filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com