System and method for utilizing flue gas residual heat of furnace body and efficiently recycling iron-containing resources

A flue gas waste heat and high-efficiency technology, applied in the field of metallurgy, can solve the problems of clogging the burner of the rotary hearth furnace, the production cannot be run smoothly, and the pretreatment process is long, so as to achieve the effects of reducing equipment investment, improving utilization efficiency and efficient recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

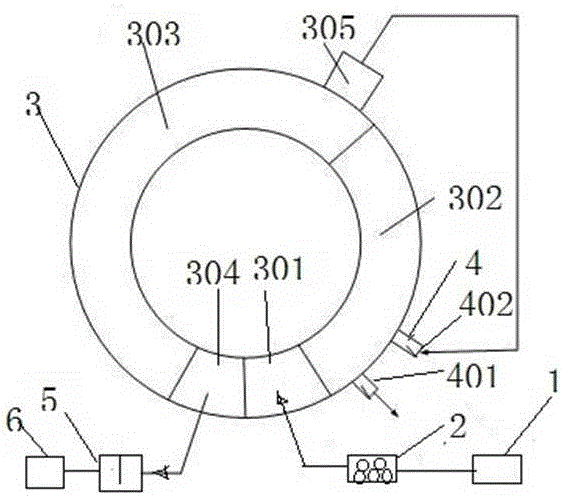

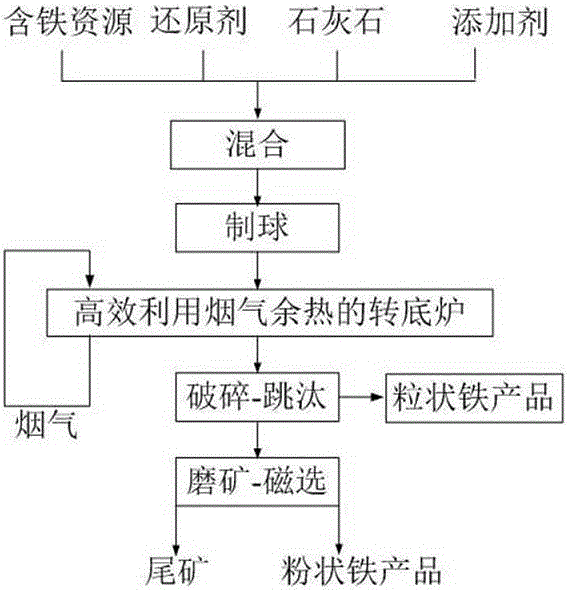

[0062] The laterite nickel ore with TFe of 19.32% and Ni content of 1.68% is selected as raw material, the reducing agent is lignite, the amount of reducing agent added is 1.1 times of the theoretical amount, the amount of limestone added is 25% of the weight of laterite nickel ore, industrial soda ash is added The amount is 3% of the weight of the laterite nickel ore. The above materials are mixed-pressed balls, and the moisture content of the water-containing pellets is 17%. The pressed water-containing pellets are directly placed in the rotary hearth furnace for drying-reduction treatment. The drying tube device is used for heating. The heat source of the drying tube device comes from the high-temperature flue gas discharged from the flue of the rotary hearth furnace; the reduction zone is heated by a burner; The minimum temperature in the drying zone is 800°C, and the maximum temperature in the reduction zone is 1390°C; the rotary hearth furnace rotates for 35 minutes, and ...

Embodiment 2

[0064] Choose TFe content 58.37%, TiO 2 Content 9.28%, V 2 o 5 Vanadium-titanium sea sand with a content of 0.51% is used as a raw material, and the reducing agent is carbon black obtained after pyrolysis of solid waste, and its addition amount is 1.3 times of the theoretical addition amount, and the addition amount of limestone and additives is 13% of the ore weight for ball making , the moisture content of the hydrous pellets is 14%, and the hydrous pellets are directly placed into the rotary hearth furnace for drying-reduction treatment. The drying area of the rotary hearth furnace is heated by a drying tube device, and the heat source of the drying tube device comes from the flue of the rotary hearth furnace The high-temperature flue gas discharged, the high-temperature flue gas discharged from the flue of the rotary hearth furnace, is sent into the flue gas inlet of the drying pipe, and then discharged from the flue gas outlet of the drying pipe; the reduction area is...

Embodiment 3

[0066] The refractory iron ore with a TFe content of 42.11% is selected as the raw material, the reducing agent is semi-coke, and its addition amount is 1.0 times of the theoretical addition amount, and the addition amount of limestone and additives is 18% of the ore weight for pelletizing, and the water content of the pellets is 14%, put the water-containing pellets directly into the rotary hearth furnace for drying-reduction treatment, the drying area of the rotary hearth furnace is heated by a drying tube device, and the heat source of the drying tube device comes from the high-temperature flue gas discharged from the flue of the rotary hearth furnace; The reduction zone is heated by burners; the included angle of the ring in the drying zone is 40°, and the angle of the ring in the reduction zone is 270°; the minimum temperature in the drying zone is 750°C, and the maximum temperature in the reduction zone is 1400°C; the rotary hearth furnace Rotating for 50 minutes, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com