Preparation method of complex lithium grease

A base grease, lithium complex technology, applied in lubricating compositions, petroleum industry, thickeners, etc., can solve the problem is not high, only reach 260-280 ℃, the anti-friction and anti-wear performance is not outstanding, the dropping point is not high, etc. problems, to achieve good high and low temperature performance and mechanical stability, improve the dropping point and anti-friction and anti-wear performance, the effect of wide temperature and pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

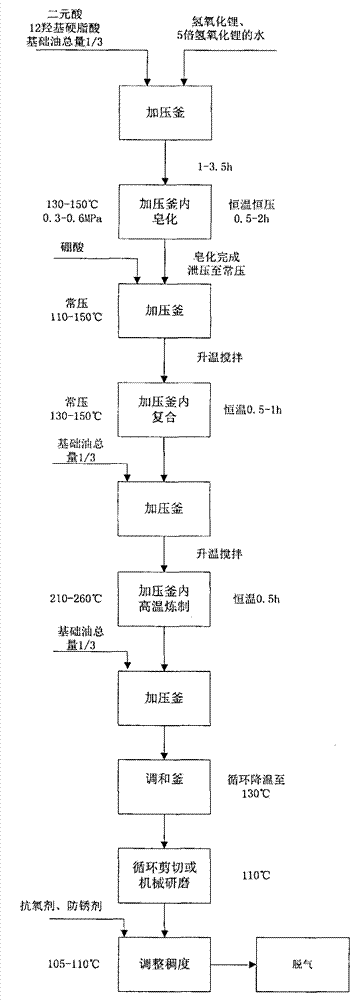

[0039] figure 1 It is a process flow chart of the preparation method of the lithium composite grease of the present invention. figure 1 Show a kind of under the condition that does not add anti-friction and anti-wear agent, by changing the adding process of boric acid, improve the dropping point of complex lithium-based grease and the preparation method of the compound lithium-based grease of anti-friction and anti-wear performance, it Including the following steps:

[0040] 1) Add one-third of the total amount of base oil or synthetic oil, 12 hydroxystearic acid, dibasic acid, lithium hydroxide and 5 times the water of lithium hydroxide into the autoclave, seal and stir.

[0041]2) Raise the temperature and pressurize, after 1-3.5 hours, when the temperature in the autoclave reaches 130-150°C and the pressure reaches 0.3-0.6Mpa, stop heating, keep the constant temperature and pressure in the autoclave for 0.5-2 hours, and carry out saponification reaction.

[0042] This pr...

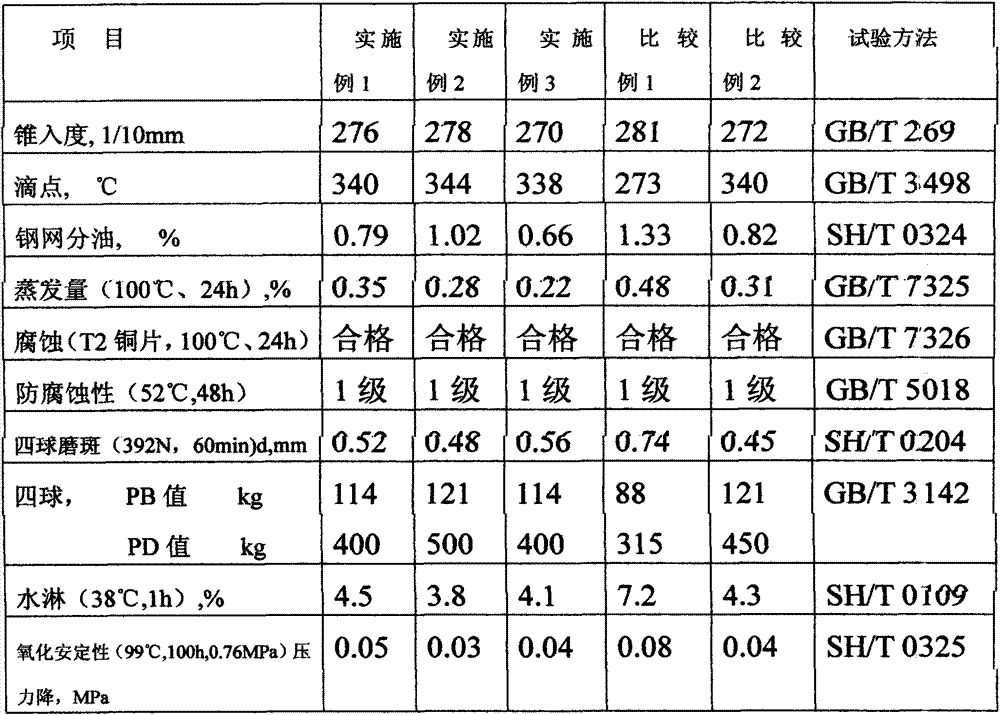

Embodiment 1

[0052] A preparation method for lithium composite grease, comprising the steps of:

[0053] 1) Add 380 kg of base oil consisting of 28% bright stock, 50% 500N and 22% 150N, 120 kg of 12 hydroxystearic acid, 35 kg of sebacic acid, 30 kg of lithium hydroxide and 150 kg of water In a 1.5M3 autoclave, seal and stir.

[0054] 2) Raise the temperature and pressurize, after 1-3.5 hours, when the temperature in the autoclave reaches 130-150°C and the pressure reaches 0.3-0.6Mpa, stop heating, keep the constant temperature and pressure in the autoclave for 0.5-2 hours, and carry out saponification reaction.

[0055] 3) After the saponification reaction is completed, release the pressure in the autoclave to make it a normal pressure state, and add 6 kg of boric acid when the temperature is 110-150° C.

[0056] 4) Heat up and stir, keep the temperature at 130-150°C for 0.5-1 hour under normal pressure, then add 380 kg of base oil consisting of 28% bright stock, 50% 500N and 22% 150N. ...

Embodiment 2

[0061] Polyalphaolefin was used as the base oil for production. Except that the base oil was different, the ratio of other raw materials and the process of the complex lithium-based lubricating grease were consistent with those in Example 1. The measurement data of embodiment 2 are shown in table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dropping point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com