Novel shape memory spraying polyurethaneurea elastomer resin bathroom product and preparation method thereof

A technology of elastomers and polyester polyols, applied in polyurea/polyurethane coatings, devices for coating liquids on surfaces, coatings, etc., can solve problems such as poor regularity, difficult molecular design, and susceptibility to moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0077] The formula is listed in Table 1 and Table 2, and the unit of each figure in Table 1 and 2 is KG. In Table 1, "NCO% (weight)", "viscosity (CP)", and "specific gravity" are all indicators of products obtained in the following step (1). "NCO% (weight)" is the mass percentage of free isocyanate groups.

[0078] (1) Preparation of component A in the formula (prepolymer component):

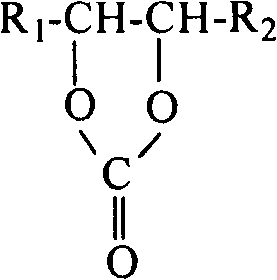

[0079] Dehydrate the polyol required for the reaction in vacuum at 90°C for 3h, then add the corresponding carbodiimide-modified MDI (C-MDI) at 75°C and mix for 1-3h, until the theoretically designed mass percentage of free isocyanate groups is reached After content, add oxazolidine water remover and reactive diluent to get A-component semi-prepolymer.

[0080] (2) Preparation of component B in the formula (resin component)

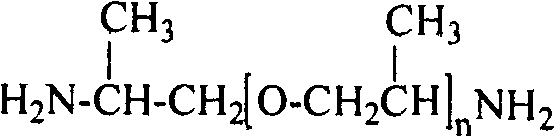

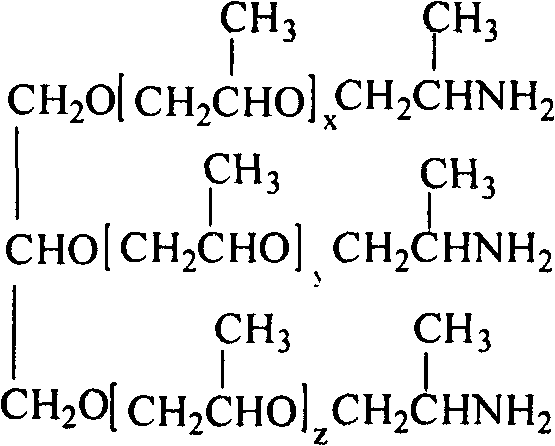

[0081] Component B resin is prepared by mixing polyoxypropylene diamine, polyoxypropylene triamine, moderator, amine chain extender, anti-biological additive, flame reta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com