Concrete anti-carbonization inhibitor and preparation method thereof

An anti-carbonation and inhibitor technology, applied in the field of new building materials, can solve the problems of the overall strength and comprehensive performance of reinforced concrete structures, the weakening of the protective effect of steel bars, and the reduction of alkalinity. The effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

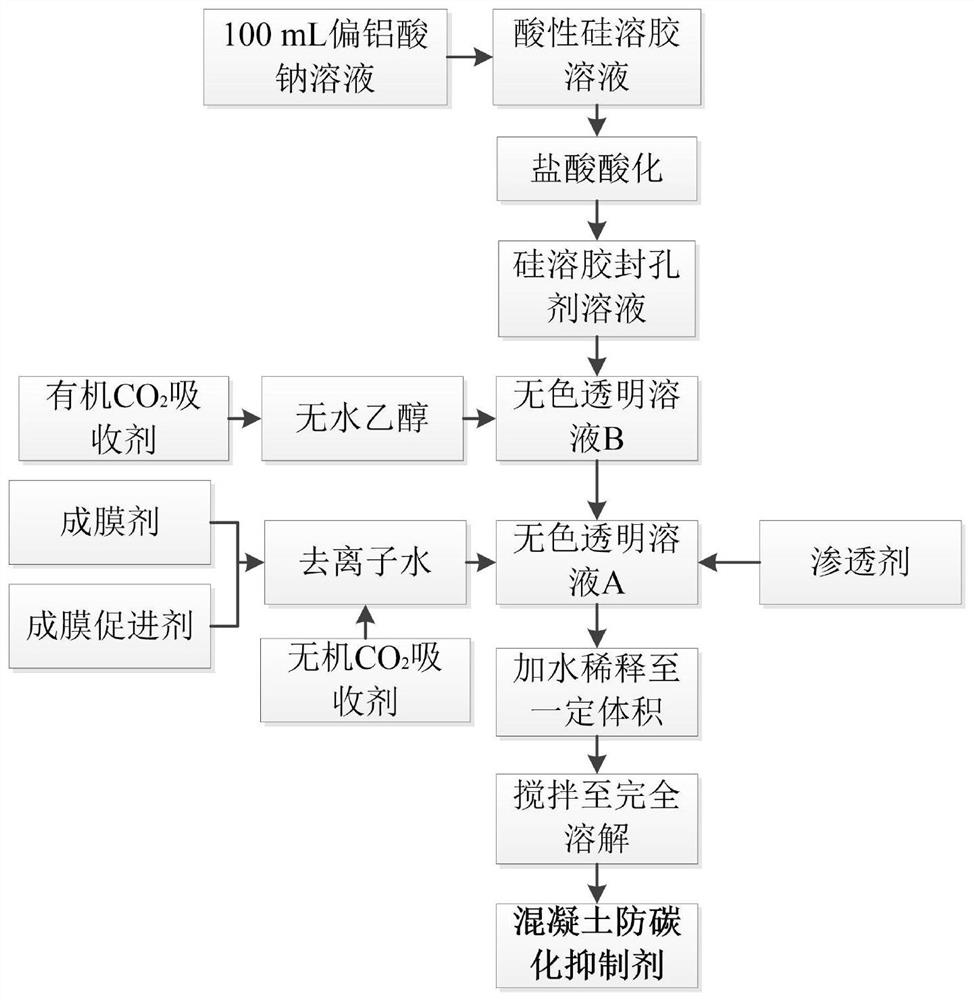

[0042] Such as figure 1 As shown, first slowly add 100mL of 2% sodium metaaluminate solution to 250g of acidic silica sol to obtain a mixed solution, then reflux the mixed solution at 120°C for 60min, and after the reaction solution is cooled to room temperature, use 1mol / L of hydrochloric acid solution to adjust the pH value of the reaction solution to 3.0 to obtain the modified silica sol sealing agent solution; then add 300g of magnesium fluorosilicate, 150g of sodium silicate and 50g of potassium carbonate into deionized water and heat at 45°C Stir until a colorless and transparent solution A is obtained; then, add 25g of triethanolamine and 25g of 2,2-dihydroxydiethylamine into absolute ethanol to prepare a colorless and transparent solution B; finally, add sealant to solution A Pore agent solution, solution B and 2g of cetyltrimethylammonium bromide were heated and stirred until completely dissolved, diluted with water to 1000mL, and milky white anti-carbonization inh...

Embodiment 2

[0044] First, slowly add 100mL of 6% sodium metaaluminate solution into 250g of acidic silica sol to obtain a mixed solution, then reflux the mixed solution at 150°C for 90min, and after the reaction solution is cooled to room temperature, use 1mol / L Hydrochloric acid solution to adjust the pH value of the reaction solution to 3.0 to obtain the modified silica sol sealing agent solution; then add 270g magnesium fluorosilicate, 90g sodium silicate and 70g potassium carbonate to deionized water, heat and stir at 55°C until the obtained A colorless and transparent solution A; then, 70g of triethanolamine was added to absolute ethanol to prepare a colorless and transparent solution B; finally, a sealing agent solution, solution B and 5g of cetyl polyoxyethylene were added to solution A Ether dimethyloctylammonium chloride, heated and stirred until completely dissolved, diluted with water to 1000mL, cooled to room temperature to obtain a milky white anti-carbonization inhibitor.

Embodiment 3

[0046] First, slowly add 100mL of 8% sodium metaaluminate solution into 250g of acidic silica sol to obtain a mixed solution, then reflux the mixed solution at 135°C for 100min, and after the reaction solution is cooled to room temperature, use 1mol / L Hydrochloric acid solution to adjust the pH value of the reaction solution to 3.0 to obtain the modified silica sol sealing agent solution; then add 400g magnesium fluorosilicate, 200g sodium silicate and 40g potassium carbonate to deionized water, heat and stir at 65°C until the obtained A colorless and transparent solution A; then, add 40g of 2,2-dihydroxydiethylamine into absolute ethanol to prepare a colorless and transparent solution B; finally, add the above-prepared sealing agent solution, Solution B and 7g of octadecyldimethylbenzyl ammonium chloride were heated and stirred until completely dissolved, diluted with water to 1000mL, and milky white anti-carbonization inhibitor was obtained after cooling to room temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com