Water-based two-component concrete sealing curing agent

A sealing and curing agent, two-component technology, applied in the field of chemical building materials, can solve the problems of difficult penetration of effective substances, reduce concrete hardness, uneven dispersion, etc., achieve high cost performance, prevent back to alkali discoloration, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

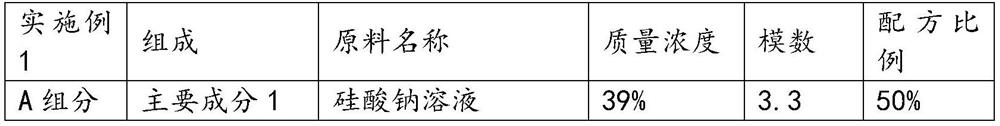

[0025] The water-based two-component concrete sealing and curing agent of the present invention includes component A and component B, and the raw material description and material composition are as follows in Table 3:

[0026] Table 3 Example 1 material description and composition of matter (the following percentages are mass percentages)

[0027]

[0028]

[0029] Preparation of Concrete Sealing and Curing Agent A: Add sodium silicate to the reaction kettle, then add potassium silicate to the reaction kettle and stir for 15 minutes. Under stirring conditions, water, sodium dodecylsulfonate, triethanolamine, Potassium methyl silicate was slowly added into the reaction kettle, and then continued to stir and mix for 60 minutes, filtered to remove insoluble impurities, and packaged for discharge. The reaction temperature is controlled between 10-30°C.

[0030] Preparation of Concrete Sealing and Curing Agent B: Put water into the reaction kettle first, then add hydrochlor...

Embodiment 2

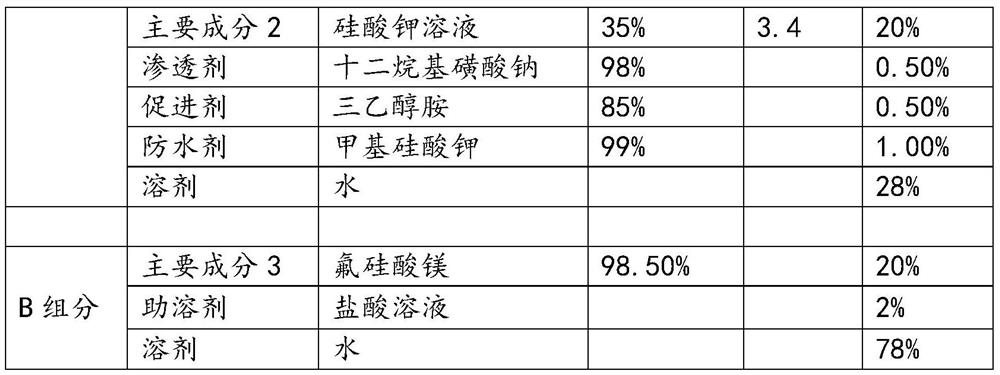

[0032] The water-based two-component concrete sealing and curing agent of the present invention comprises component A and component B, and the raw material description and material composition are as follows in Table 4:

[0033] Table 4 Example 2 material description and composition of matter

[0034]

[0035]

[0036] Preparation of Concrete Sealing and Curing Agent A: Add sodium silicate to the reaction kettle, then add potassium silicate to the reaction kettle and stir for 15 minutes. Under stirring conditions, water, sodium dodecylsulfonate, triethanolamine, Potassium methyl silicate was slowly added into the reaction kettle, and then stirred and mixed at 20°C for 60 minutes, filtered to remove insoluble impurities, and packaged for discharge. The reaction temperature is controlled between 10-30°C.

[0037] Preparation of Concrete Sealing and Curing Agent B: Put water into the reaction kettle first, then add hydrochloric acid solution and stir for 15 minutes, finall...

Embodiment 3

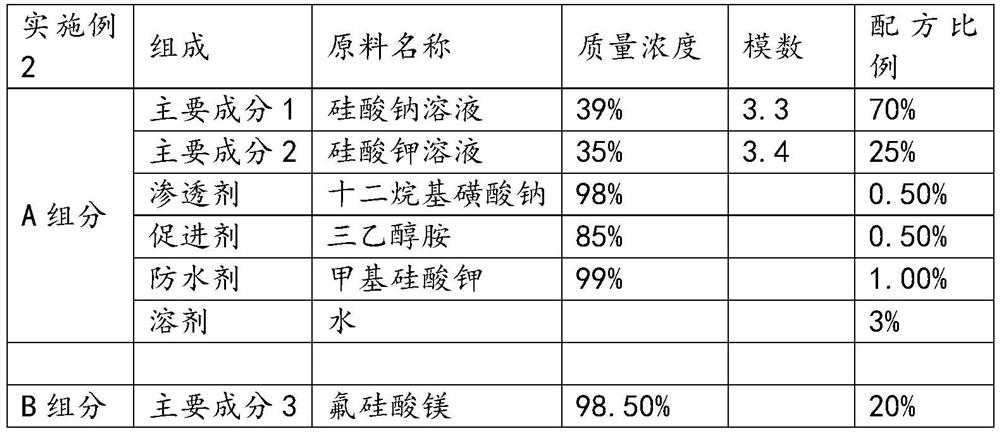

[0039] The water-based two-component concrete sealing and curing agent of the present invention comprises component A and component B, and the raw material description and material composition are as follows in Table 5:

[0040] Table 5 Example 3 material description and composition of matter

[0041]

[0042] Preparation of Concrete Sealing and Curing Agent A: Add sodium silicate to the reaction kettle, then add potassium silicate to the reaction kettle and stir for 15 minutes. Under stirring conditions, water, sodium dodecylsulfonate, triethanolamine, Potassium methyl silicate was slowly added into the reaction kettle, and then continued to stir and mix for 60 minutes, filtered to remove insoluble impurities, and packaged for discharge. The reaction temperature is controlled between 10-30°C.

[0043] Preparation of Concrete Sealing and Curing Agent B: Put water into the reaction kettle first, then add hydrochloric acid solution and stir for 15 minutes at 20°C, finally ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com