Low-alkali setting accelerator, and preparation method and application thereof

A technology of quick-setting agent and stabilizer, which is applied in the field of low-alkali quick-setting agent and its preparation, can solve the problems of easy crystallization and freezing, poor low temperature performance, reduction of concrete strength, etc., and achieves fast setting and hardening of cement, low viscosity, convenient on-site construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

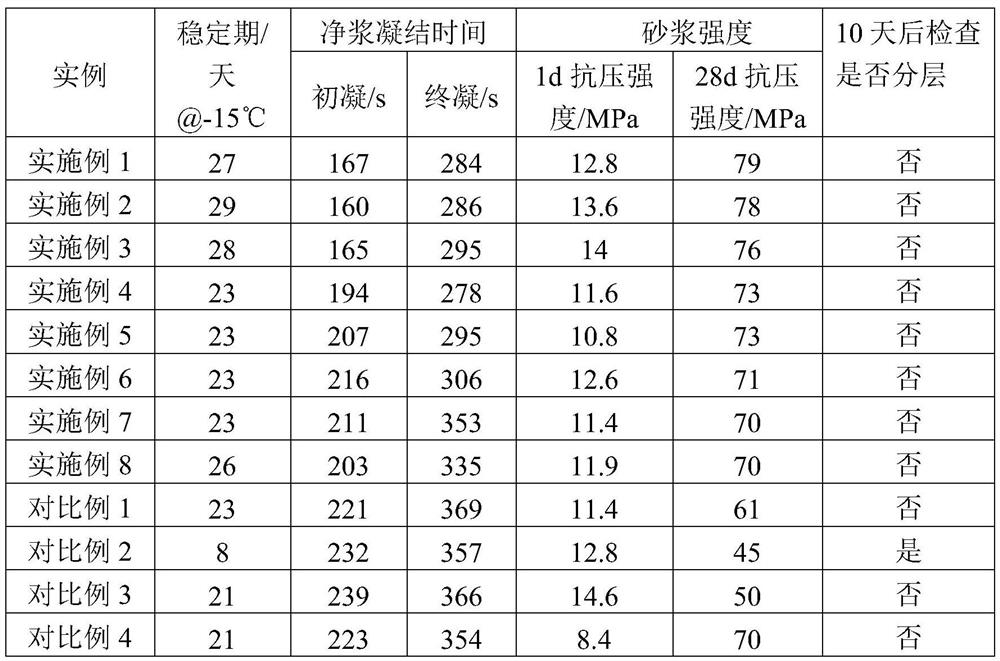

Examples

Embodiment 1

[0045] Step 1. Mix aluminum sulfate I, sodium metaaluminate and water I to obtain solution I, and stir for 10 minutes;

[0046] Step 2. Add magnesium fluorosilicate and hydrofluoric acid to solution I in turn to obtain solution II, and stir for 20 minutes;

[0047] Step 3, mixing aluminum sulfate II, water II and solution II to obtain solution III, stirring for 20 minutes;

[0048] Step 4. Mix aluminum sulfate III, triethanolamine, hydroxymethyl cellulose (stabilizer), sericite (inorganic modified material, 50 nm in size) and solution III, and stir for 2 hours to obtain a low-alkali quick-setting agent.

[0049] Wherein, based on the total weight of the low-alkali quick-setting agent, the total amount of aluminum sulfate is 33% by weight, wherein the amount of aluminum sulfate I is 11% by weight, the amount of aluminum sulfate II is 11% by weight, and the amount of aluminum sulfate III is 11% by weight. The consumption is 11% by weight; the consumption of sodium metaaluminate...

Embodiment 2

[0051] According to the method of Example 1, the difference is that the sericite with a size of 50 nm is replaced with talcum powder with a size of 100 nm.

Embodiment 3

[0053] Step 1. Mix aluminum sulfate I, sodium metaaluminate and water I to obtain solution I, and stir for 10 minutes;

[0054] Step 2. Add magnesium fluorosilicate and hydrofluoric acid to solution I in turn to obtain solution II, and stir for 20 minutes;

[0055] Step 3, mixing aluminum sulfate II, water II and solution II to obtain solution III, stirring for 20 minutes;

[0056] Step 4. Mix aluminum sulfate III, triethanolamine, hydroxyethyl cellulose (stabilizer), sericite (inorganic modified material, 5 nm in size) and solution III, and stir for 2 hours to obtain a low-alkali quick-setting agent.

[0057] Wherein, based on the total weight of the low-alkali quick-setting agent, the total amount of aluminum sulfate is 40% by weight, wherein the amount of aluminum sulfate I is 12% by weight, the amount of aluminum sulfate II is 16% by weight, and the amount of aluminum sulfate III is 16% by weight. The consumption is 12% by weight; the consumption of sodium metaaluminate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com