Film-forming permeable waterproof material, preparation method and application thereof

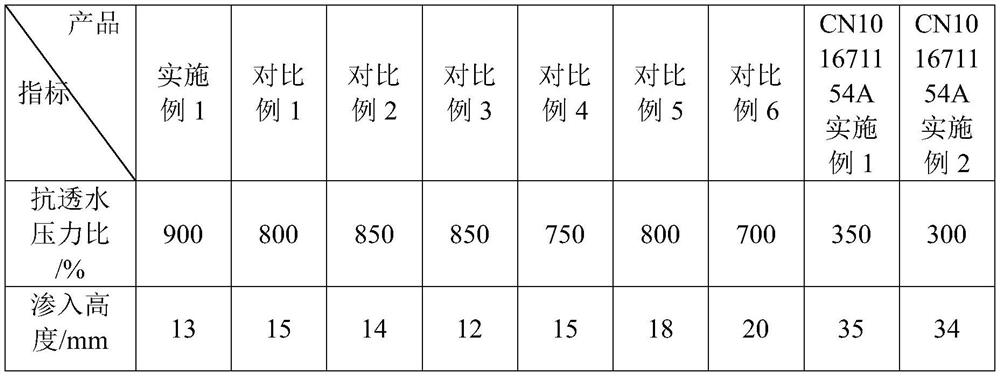

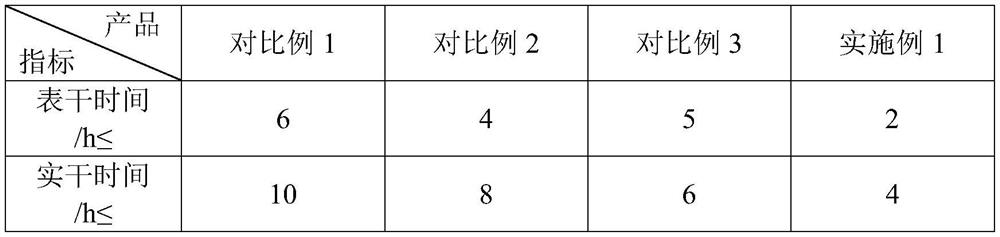

A waterproof material and film-forming technology, which is applied in building thermal insulation materials, building components, etc., can solve the problems of unstable waterproof effect, long curing time, and low impermeability of film-forming materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] For waterproof materials that are both film-forming and permeable, the components are calculated by weight:

[0070] Component A: 35 parts of sodium silicate aqueous solution (solid content 25%), 0.1 part of surfactant, 0.5 part of reaction delay agent, 0.15 part of reducing agent, 2.5 parts of reaction accelerator, 0.08 part of antifreeze agent, metal ion blocker 0.2 parts, 0.6 parts of surface strengthening agent, 0.3 parts of antirust agent, 0.5 parts of photoinitiator, 0.5 parts of crosslinking agent, 61 parts of water, 45 parts of acrylate emulsion.

[0071] Component B: 45 parts of white cement, 6 parts of gypsum, 7.5 parts of silica fume, 25 parts of mineral powder, 7.5 parts of fly ash, 0.6 parts of citric acid, 3.5 parts of magnesium fluorosilicate, 7.5 parts of magnesium oxide, and 3.5 parts of sodium silicate parts, 0.6 parts of reinforcing components, and 0.6 parts of fumed silica.

[0072] Wherein, in component A: sodium silicate is an aqueous solution of ...

Embodiment 2

[0074] For waterproof materials that are both film-forming and permeable, the components are calculated by weight:

[0075] Component A: 30 parts of sodium silicate, 0.05 part of surfactant, 0 part of reaction delay agent, 0.1 part of reducing agent, 0 part of reaction accelerator, 0.06 part of antifreeze agent, 0.1 part of metal ion blocking agent, and 0.4 part of surface strengthening agent parts, 0.2 parts of antirust agent, 0.25 parts of photoinitiator, 0.25 parts of crosslinking agent, 53 parts of water, and 40 parts of acrylate emulsion.

[0076]Component B: 40 parts of white cement, 5 parts of gypsum, 5 parts of silica fume, 20 parts of mineral powder, 5 parts of fly ash, 0.25 parts of citric acid, 2 parts of magnesium fluorosilicate, 5 parts of magnesium oxide, 2 parts of sodium silicate parts, 0.25 parts of reinforcing components, and 0.25 parts of fumed silica.

[0077] Wherein, in component A: sodium silicate is an aqueous solution of sodium silicate (solid content...

Embodiment 3

[0079] For waterproof materials that are both film-forming and permeable, the components are calculated by weight:

[0080] Component A: 40 parts of sodium silicate, 0.15 parts of surfactant, 1 part of reaction delay agent, 0.2 parts of reducing agent, 5 parts of reaction accelerator, 0.1 part of antifreeze agent, 0.3 part of metal ion blocking agent, and 0.8 part of surface strengthening agent parts, 0.4 parts of rust inhibitor, 0.75 parts of photoinitiator, 0.75 parts of crosslinking agent, 69 parts of water, and 50 parts of acrylate emulsion.

[0081] Component B: 50 parts of white cement, 7 parts of gypsum, 10 parts of silica fume, 30 parts of mineral powder, 10 parts of fly ash, 1 part of citric acid, 5 parts of magnesium fluorosilicate, 10 parts of magnesium oxide, 5 parts of sodium silicate 1 part, 1 part of reinforcing component, 1 part of fumed silica.

[0082] Wherein, in component A: sodium silicate is an aqueous solution of sodium silicate (solid content 25%), the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com