Liquid alkali-free accelerator and room-temperature synthesis process thereof

A technology of quick-setting agent and liquid state, which is applied in the field of liquid alkali-free quick-setting agent and its synthesis process at room temperature, can solve the problems such as the harm of injection equipment, the large consistency of alkali-free setting accelerator, and the large amount of inorganic acid, and can solve the problem of low strength in one day. , The effect of accelerating the final setting time and increasing the pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

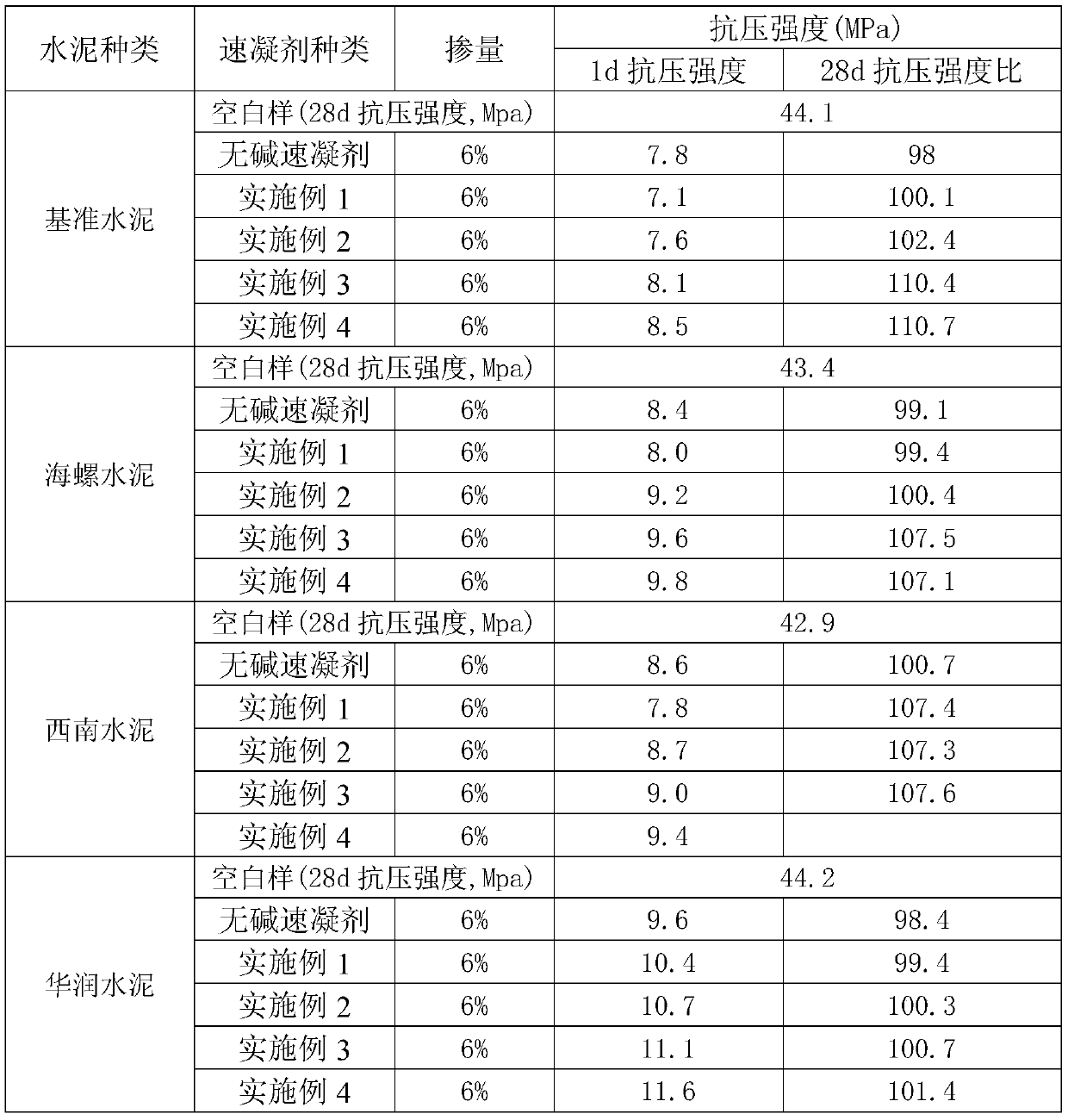

Embodiment 1

[0026] Add 35 parts of water to the bottom of the kettle and turn on the stirrer. Add 4.5 parts of magnesium fluorosilicate, 1.5 parts of ferrous sulfate, 3.5 parts of urea, 2 parts of organosilica sol in sequence, dissolve for 20 minutes and then add 48 parts of sulfuric acid After dissolving the aluminum for 30 minutes, add 4.5 parts of glycerol, and add 1 part of AMP-95 after 20 minutes. After reacting for 20 minutes, a liquid alkali-free quick-setting admixture is obtained.

[0027] Among them, the components of each group mentioned above are calculated in parts by weight.

Embodiment 2

[0029] Add 31 parts of water to the bottom of the kettle and turn on the stirrer. Add 5 parts of magnesium fluorosilicate, 2 parts of ferrous sulfate, 4 parts of urea, 2.5 parts of organosilica sol, and add 49 parts of sulfuric acid after dissolving for 20 minutes. After dissolving the aluminum for 30 minutes, add 5 parts of glycerol, and add 1.5 parts of AMP-95 after 20 minutes. After reacting for 20 minutes, the liquid alkali-free quick-setting agent is obtained at room temperature.

[0030] Among them, the components of each group mentioned above are calculated in parts by weight.

Embodiment 3

[0032] Add 27 parts of water to the bottom of the kettle and turn on the stirrer. Add 5.5 parts of magnesium fluorosilicate, 2.5 parts of ferrous sulfate, 4.5 parts of urea, 3 parts of organosilica sol in sequence, dissolve for 20 minutes and then add 50 parts of sulfuric acid After dissolving the aluminum for 30 minutes, add 5.5 parts of glycerol, and add 2 parts of AMP-95 after 20 minutes. After reacting for 20 minutes, the liquid alkali-free quick-setting admixture is obtained.

[0033] Among them, the components of each group mentioned above are calculated in parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com