Special curing agent for indoor cement ground, and use method thereof

A curing agent and ground technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of unfavorable environmental protection, low strength, small strength contribution of Portland cement, etc., to achieve easy portability and handling, and enhanced wear resistance. , Save the effect of a long validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

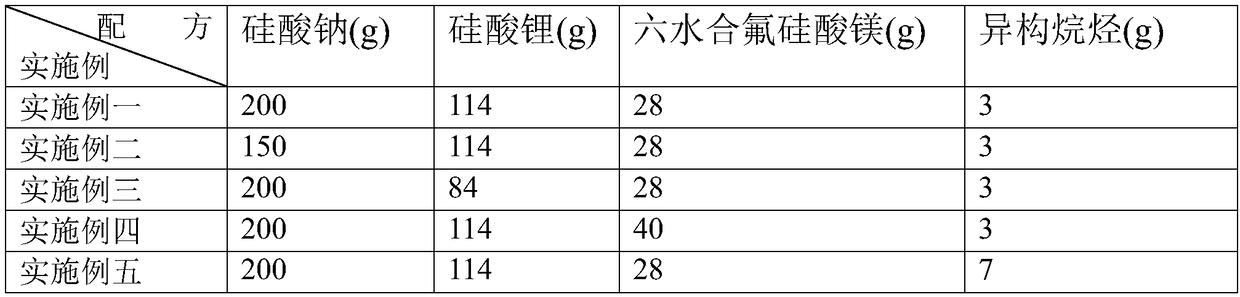

[0054] A special curing agent for indoor cement floor, which contains sodium silicate, lithium silicate, magnesium fluorosilicate hexahydrate and isoparaffin, in the form of white dry powder.

[0055] Its specific formula is 200 parts of sodium silicate, 114 parts of lithium silicate, 28 parts of magnesium fluorosilicate hexahydrate, and 3 parts of isoparaffin.

[0056] Wherein magnesium fluorosilicate hexahydrate (mass fraction ≥ 75%) is produced by oneself, and the reaction steps are as follows,

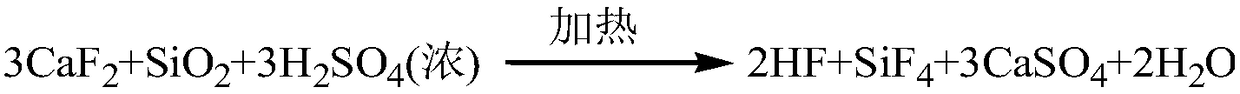

[0057] Fluorosilicic acid is made by heating reaction of fluorite powder, silica sand and concentrated sulfuric acid. Calcium fluoride, the main component of fluorite powder, and silicon dioxide, the main component of silica sand, react with concentrated sulfuric acid to produce hydrogen fluoride and tetrafluoride as raw materials for preparing fluosilicic acid. SiO, the main reaction is

[0058]

[0059] Calcium sulfate is slightly soluble in water and will form precipitates. ...

Embodiment 2

[0066] A special curing agent for indoor cement floor, the difference between embodiment two and embodiment one is that 84 parts of lithium silicate are added in its specific formula.

Embodiment 3

[0068] A special curing agent for indoor cement floor, the difference between embodiment three and embodiment one is that 150 parts of sodium silicate are added in its specific formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com