Hazardous chemical substance-free magnesium-aluminum fluoride system alkali-free setting accelerator without hazardous chemical substances and preparation method thereof

A technology of magnesium fluoride and accelerator, which is applied in the field of building materials, can solve problems such as lack of magnesium fluoride and aluminum compounds, impact on workers' health, and damage to workers' health, so as to achieve superior quick-setting effect, shorten initial setting and final setting. The coagulation time and the effect of sufficient component reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

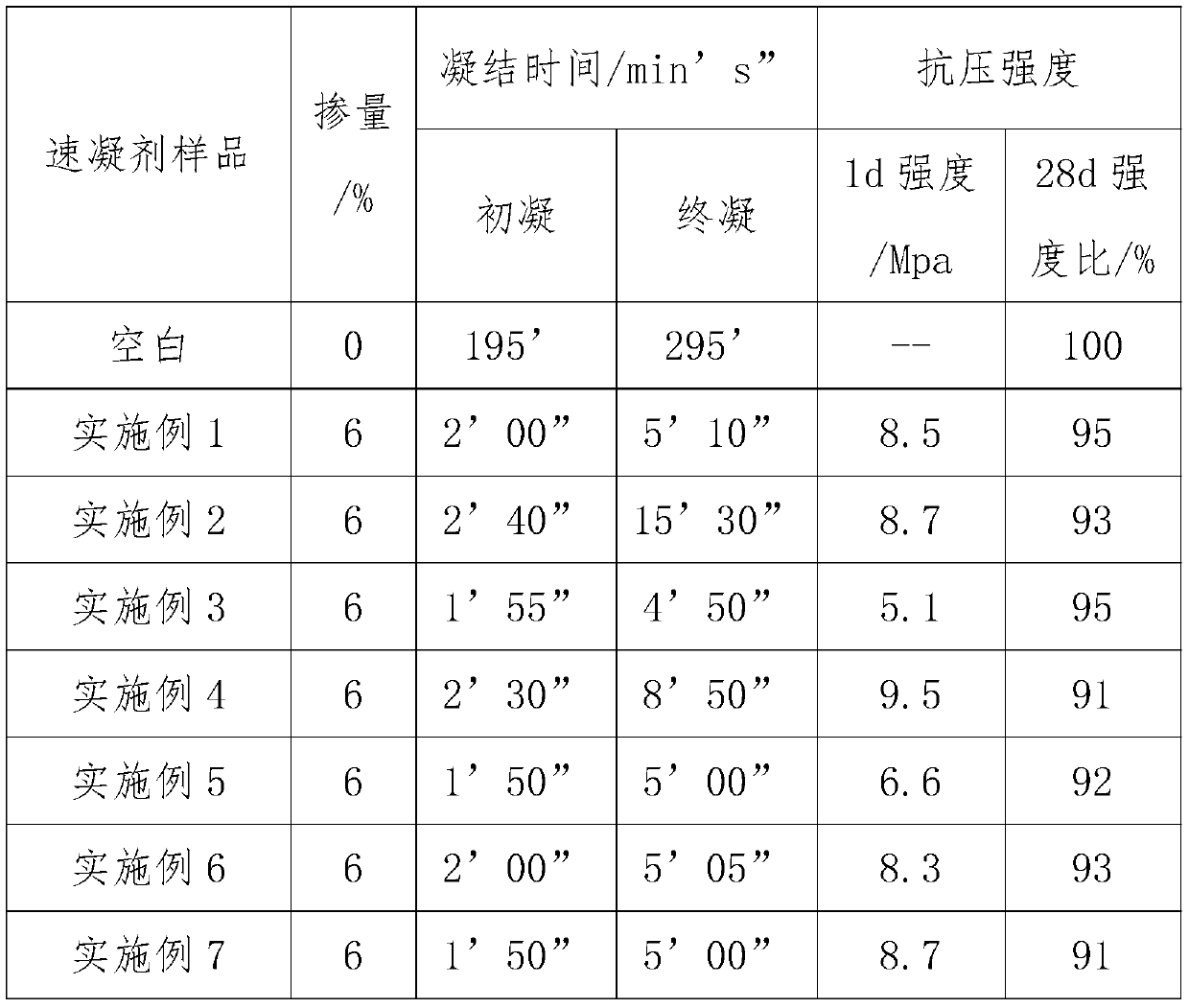

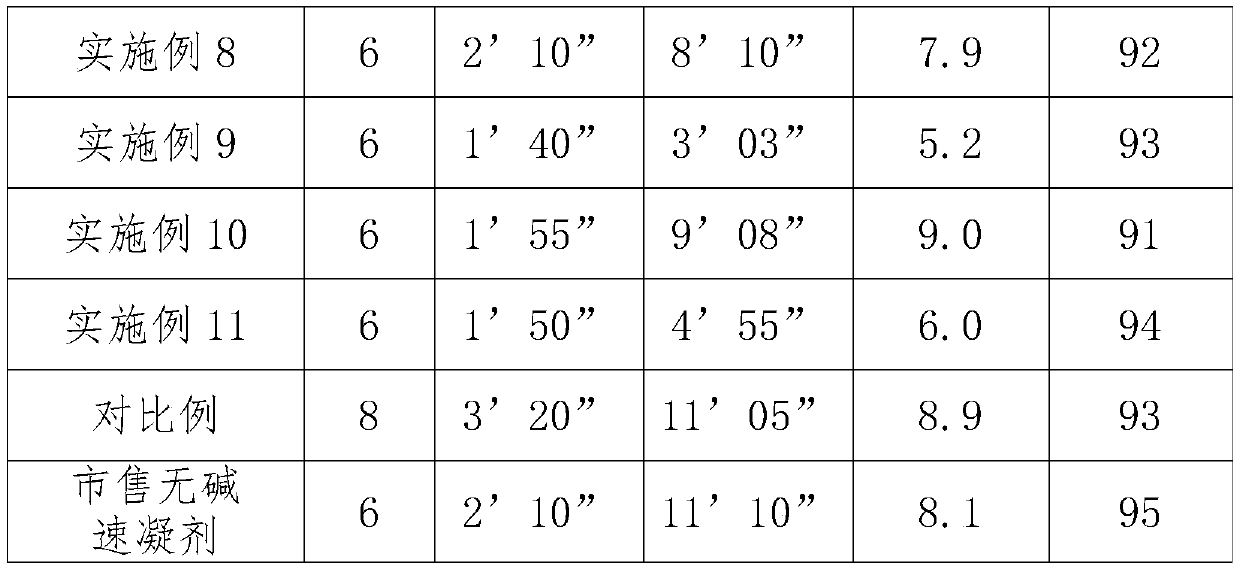

Examples

Embodiment 1

[0046] A non-hazardous chemical-free magnesium-aluminum fluoride system alkali-free quick-setting agent, comprising the following components, calculated in parts by weight, 47 parts of aluminum sulfate, 6.5 parts of magnesium fluorosilicate, 2 parts of cryolite, and 10 parts of magnesium sulfate, 1 part of magnesium hydroxide, 0.1 part of polyethyleneimine, 2 parts of urea, 5 parts of diethanolamine, 26.5 parts of water.

[0047] Preparation:

[0048] S1: Mix and heat water, urea, magnesium hydroxide, polyethyleneimine and magnesium fluorosilicate to 40-45°C, and stir for 30 minutes;

[0049] S2: Put aluminum sulfate, magnesium sulfate and cryolite into S1, heat to 60-65°C, and stir for 30 minutes;

[0050] S3: pump diethanolamine into S2, and stir at a constant temperature of 60-65°C for 1.5 hours to obtain a non-hazardous chemical-free magnesium-aluminum fluoride system alkali-free accelerator.

Embodiment 2

[0052] A non-hazardous chemical-free magnesium-aluminum fluoride system alkali-free accelerator, comprising the following components, calculated in parts by weight, 47 parts of aluminum sulfate, 3 parts of magnesium fluorosilicate, 2 parts of cryolite, and 10 parts of magnesium sulfate, 1 part of magnesium hydroxide, 0.1 part of polyethyleneimine, 2 parts of urea, 5 parts of diethanolamine, 30 parts of water.

[0053] Preparation:

[0054] S1: Mix and heat water, urea, magnesium hydroxide, polyethyleneimine and magnesium fluorosilicate to 40-45°C, and stir for 30 minutes;

[0055] S2: Put aluminum sulfate, magnesium sulfate and cryolite into S1, heat to 60-65°C, and stir for 30 minutes;

[0056] S3: pump diethanolamine into S2, and stir at a constant temperature of 60-65°C for 1.5 hours to obtain a non-hazardous chemical-free magnesium-aluminum fluoride system alkali-free accelerator.

Embodiment 3

[0058] A non-hazardous chemical-free magnesium-aluminum fluoride system alkali-free accelerator, comprising the following components, calculated in parts by weight, 47 parts of aluminum sulfate, 8 parts of magnesium fluorosilicate, 5 parts of cryolite, and 10 parts of magnesium sulfate, 1 part of magnesium hydroxide, 0.1 part of polyethyleneimine, 2 parts of urea, 5 parts of diethanolamine, 25 parts of water.

[0059] Preparation:

[0060] S1: Mix and heat water, urea, magnesium hydroxide, polyethyleneimine and magnesium fluorosilicate to 40-45°C, and stir for 30 minutes;

[0061] S2: Put aluminum sulfate, magnesium sulfate and cryolite into S1, heat to 60-65°C, and stir for 30 minutes;

[0062] S3: pump diethanolamine into S2, and stir at a constant temperature of 60-65°C for 1.5 hours to obtain a non-hazardous chemical-free magnesium-aluminum fluoride system alkali-free accelerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com