Alkali-free accelerator as well as preparation method and application thereof

A technology of accelerators and accelerators, applied in the field of accelerators, can solve the problems of not being able to store for a long time, the performance of accelerators is ineffective, and not stable enough, it is not easy to achieve later strength, improve strength, and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

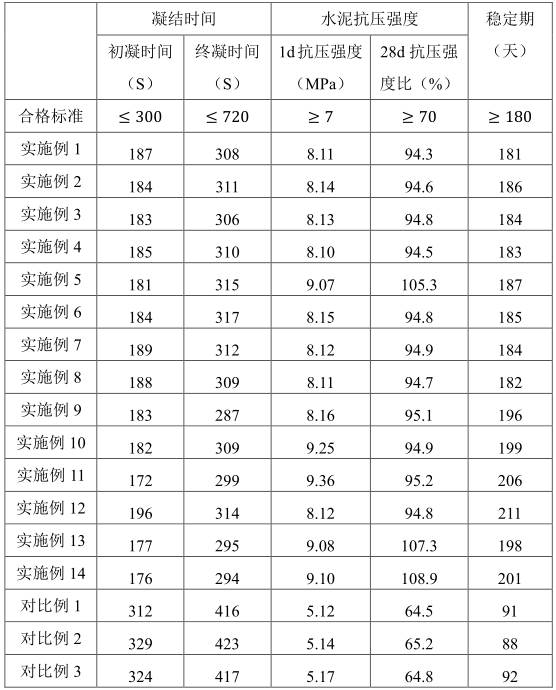

Examples

Embodiment 1

[0039] The present embodiment discloses an alkali-free setting accelerator, which is composed of the following raw materials:

[0040] Aluminum sulfate; Magnesium fluorosilicate; Phosphoric acid; Sodium sulfate; Alcohol amine; Coagulant; Xanthan gum; Water.

[0041] The present embodiment also discloses a preparation method of an alkali-free setting accelerator, comprising the following steps:

[0042] (1) Add water, sodium sulfate and coagulant according to the amounts in Table 2, and stir evenly at a rotating speed of 180 r / min to obtain a premix;

[0043] (2) Then the reaction kettle was heated to 48°C, and magnesium fluorosilicate, aluminum sulfate and xanthan gum were added to the premix (the dosage is shown in Table 2), and the stirring was carried out at a speed of 150 r / min. Continue to stir for 15min;

[0044] (3) The reaction kettle was heated to 65°C, and phosphoric acid and alkanolamine were added dropwise to the reaction kettle (see Table 2 for the dosage), and ...

Embodiment 2

[0047] The difference from Example 1 is:

[0048] In step (2), the reaction kettle was heated to 52°C, magnesium fluorosilicate, aluminum sulfate and xanthan gum were added to the premix material (see Table 2 for the dosage), and the mixture was stirred at a speed of 150 r / min while adding. Continue to stir for 25min after completion; in step (3), the reaction kettle is heated to 70°C, phosphoric acid and alcohol amine are dropped into the reaction kettle, and stirring is added while dropping at a speed of 100r / min, and the temperature is kept for 45min after dropping.

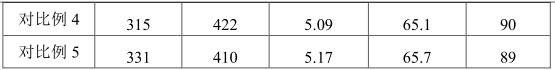

[0049] The consumption of each raw material in the embodiment 1-4 is shown in Table 2, and the unit is kg.

[0050] Table 2

[0051]

[0052]

Embodiment 5

[0054] The difference from Example 4 is that triethanolamine and diethanolamine are mixed in a mass ratio of 7:15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com